Calhoun Super Structure

CC stands for compression coupler. This unique design combines a coupler and gusset which allows for a longer transfer of pressure over the connecting cords. This design allows us to achieve greater design capacity over the competitor's flat plate gusset design that transfers the pressure to the end of the tube only.

Built to Adapt.

Our CC series is built for both commercial and Agricultural use. And our versatile options allows for you to make the building right for your application.

Options

• Engineered Wood post

• Steel Legs with different height options 2’,4’,6’,8’ & 10’

• 4’ Eave Bunker Covers

• Roof Vent Support Systems

• Individual Keder panel system ILO one piece cover

• PVC available upon request

Foundations

• Wood posts

• I-Beam

• Concrete pier

• Pre cast Blocks & walls

• Poured in place Concrete walls

• Helical anchors

• Sea Containers

CC- Series Standard Features

• Hot Dipped Galvanized (HDG) Steel Frame

• Stainless Steel Cables

• HDG Hardware

• 12 oz High Density polyethylene (HDPE)

• One piece Cover (2 covers or more on building over 100’ long)

Widths 50’, 60’,65’, 72’ & 82’

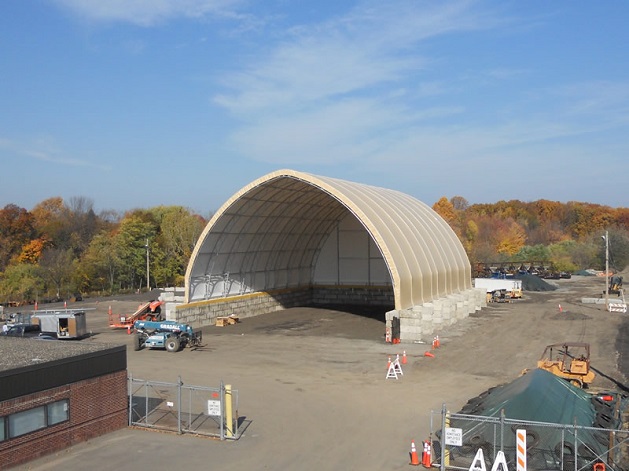

HT - stands for High Top. Our HT series uses the same unique compression coupler design as the CC series, but utilizes larger top and bottom cords and a deeper truss depth. The HT series comes standard with our individual Keder panel system. Our individual Keder panel system is added to all buildings over the width of 60’. Click here to see why.

The HT series brings you to greater heights!

The HT design is ideal for those customers looking for extra interior height in their structure. The extra height and clear span space makes unloading large trucks easy and worry free. The HT design also makes it a “tank” in heavy snow load areas, especially in the 50’ & 60’s.

Options

• Steel Legs with different height options 2’,4’,6’,8’ & 10’

• 4’ Eave Bunker Covers

• Roof Vent Support Systems

• PVC available upon request

Foundations

• I- Beam

• Concrete pier

• Pre cast Blocks & walls

• Poured in place Concrete walls

• Helical anchors

• Sea Containers

HT- Series Standard Features

• Hot Dipped Galvanized (HDG) Steel Frame

• Stainless Steel Cables

• HDG Hardware

• 12 oz High Density polyethylene (HDPE)

• Individual Keder Panel System

Widths from 30' to 200'

VP - stands for versatile product. The versatile design of our VP allows us to interchange the different series of truss's to make up any size of building for any type of application, anywhere in the world.

Distinctively practical.

The VP's distinctive, traditional look with 24' eaves finished in wood or steel, will leave you wondering if it is even a fabric building.Our rounded shoulder design finished in fabric offers a more practical and economical alternative for the VP series. The VP series is engineered to suit your needs.

Options

• Steel Legs with different height options 8' & 14'

• 4' Eave

• Roof Vent Support Systems

• PVC available upon request

Foundations

• I-Beam

• Concrete pier

• Pre cast Blocks & walls

• Poured in place Concrete walls

• Рelical anchors

• Sea Containers

VP- Series Standard Features

• Hot Dipped Galvanized (HDG) Steel Frame

• Stainless Steel Cables

• HDG Hardware

• 12 oz High Density polyethylene (HDPE)

• Individual Keder Panel System

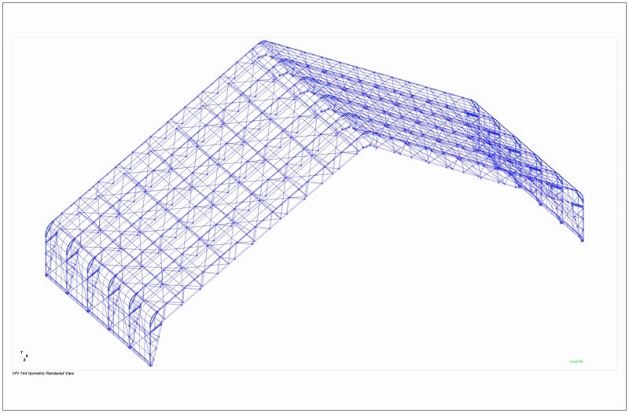

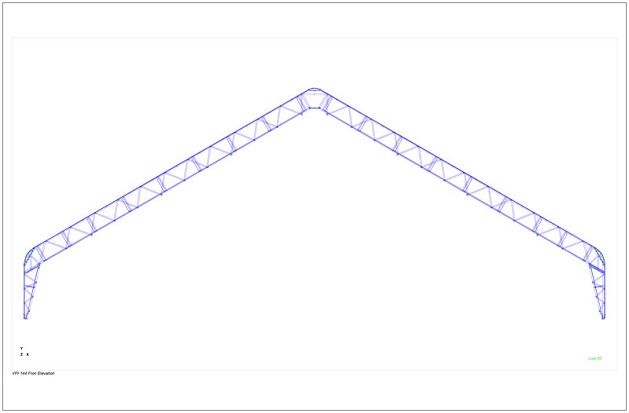

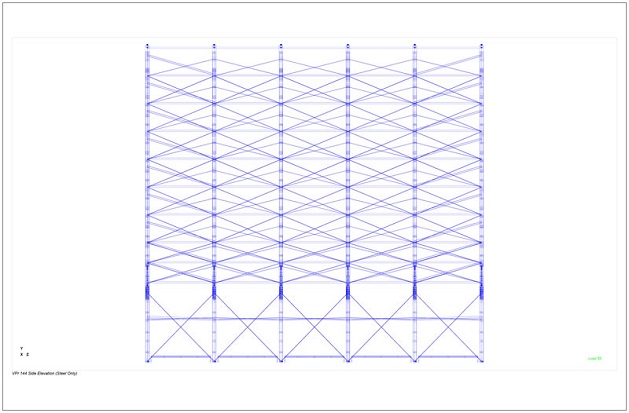

Calhoun Super Structures uses cutting edge technology when it comes to engineering your fabric tension building to your exact site loads, use and application. Being one of the only names in the industry to utilize 3D Finite Element Non-Linear Analysis, we can give detailed points of pressure or stresses on each specific area of your building. Knowing that each building, location and application is unique, we use only the most precise and premier technology currently available. Our team of highly trained Engineers, Designers and Detailers are what sets Calhoun Super Structures apart from the competition. They have made it their personal mission to ensure that your building is engineered to be the strongest, most reliable structure on the market.

Calhoun Super Structures- 3D Finite Element Nonlinear Analysis

The present standard of care (as established by the nature of the analysis typically completed in when assessing the adequacy of the structural elements in a tensioned fabric structure) involves a linear elastic portal frame analysis wherein the load is approximated and applied to a typical or critical frame in two dimensions. In this way, a linear elastic portal frame analysis reasonably predicts the vertical load carrying capacity of the frame in plane so long as the assumption holds that the frames remain in plane and the members providing sway stability have adequate stiffness to ensure this assumption remains true. Unfortunately, the behavior of the fabric cladding prevents this assumption from holding true in most cases and is never true in cases where the fabric is tensioned over the frame without direct mechanical attachment as is often the case. The portal frame analysis procedure must then rely upon hand calculations sourcing code specified alignment charts and still more approximations to estimate the out of plane (lateral) forces from the load and fabric response to the supporting elements. For these structures, the out of plane forces and load path are often quite complex and currently not broadly understood as there has been little or no full scale testing. Thus, these forces cannot be accurately predicted using proven and existing elastic approximation methods for approximating lateral forces as with other types of standard construction. Without an accurate method to conservatively approximate the out of plane forces, combined force checks cannot be thoroughly investigated. One consequence of relying on this approach and asserting the frames remain plane when in fact they do not is that the effective distance between bracing members for members in compression may be larger than the actual distance because these members lack adequate stiffness or pre tension initially or due to the fact that they are nearing their proportional limits in compression themselves. When this occurs even a conservative assumption regarding the effective distance between bracing equal to the actual distance may prove disastrous leading to catastrophic failures given the effective distances may have been grossly underestimated.

Calhoun Super Structures believes it is the duty of pre-engineered manufacturing to maintain high levels of both reliability and sustainability meaning that the structures provided should be the safest and most environmentally responsible structures possible while still maintaining cost efficiency. This is a difficult task given that these cornerstones are often scaled in opposing fashion. As such, a balance must be achieved between them in order to arrive at a design that satisfies each to above minimum standards.

In order to achieve this end, Calhoun Super Structures utilizes advanced 3D finite element nonlinear analysis to investigate thoroughly the load carrying capacity of their structures in response to the code specified loading. The advantage being that the complex nonlinear behavior of the fabric and three dimensional behavior of the system is fully addressed such that the approximations and estimates required when assuming plane frames are rendered obsolete. Given the reliability of the structural systems is derived from the standard of care which currently involves a series of approximations that do not hold true for these structures, the result is a structural system that exceeds the code specified safety limits while providing exceptional efficiencies in design. These efficiencies are then passed along to the customer completing the cycle.

The Hot-Dipped Galvanizing Process

The Hot Dipped galvanizing process means that Calhoun Super Structures last longer. Studies show that next to stainless steel, hot dipped galvanizing (HDG) is the best protection against rust and weathering. Hot dip galvanizing process makes our trusses strong and more reliable while creating a smooth surface that won't snag or tear the cover.

Here's how it works.

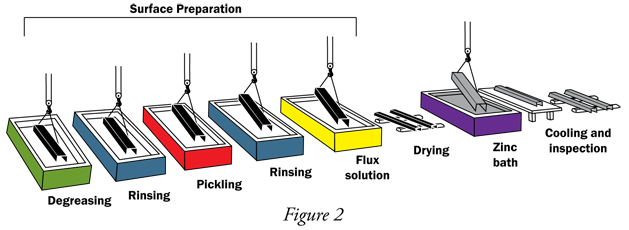

Surface preparation

Galvanizing involves bonding zinc to steel, and surface preparation is extremely important. If it is not done correctly, the zinc won't adhere to the steel and sections will be left uncoated. Our steel undergoes three stages of preparation.

Caustic Cleaning

A hot alkali solution removes organic contaminants, such as dirt, paint markings, grease and oil from the metal surface. Epoxies, vinyl, asphalt, or welding slag must be removed before galvanizing by grit blasting, sand blasting or other mechanical means.

Acid Pickling

Scale and rust are removed from the steel surface by pickling in a dilute solution of hot sulphuric acid or ambient temperature hydrochloric acid.

Fluxing

Fluxing removes oxides and prevents further oxides from forming on the surface of the metal prior to galvanizing. The steel is dipped into an aqueous solution of zinc ammonium chloride. The material is then dried prior to immersion in molten zinc.

Galvanizing

Each welded truss is completely immersed in a bath consisting of a minimum of 98% pure molten zinc at a temperature of about 840°F (449°C). The zinc metal then reacts with the iron on the steel surface to form a zinc/iron inter-metallic alloy. The trusses are then withdrawn slowly from the galvanizing bath, and the excess zinc is removed by draining and vibrating. Because the galvanization process involves total immersion, all surfaces are coated- providing protection for both the outside and the inside of the steel tubing used in the trusses.

Inspection

After the trusses have dried, the galvanizer closely scrutinizes the coating thickness and appearance. Through a battery of physical and laboratory tests, they determine thickness uniformity, adherence and appearance. Every Calhoun super Structure is galvanized according to long-established, well accepted and approved standards of ASTM, the Canadian Standards Association (CSA), and the American Standards of State Highway and Transportation Officials (AASHTO). These standards cover everything from minimum required coating thickness for various categories of galvanized items to the composition of the zinc metal used in the process.