Home >

Suppliers Companies

> Sepro Mineral Systems Corp. >

Products

> > Screening > SEPRO-ATALAY SIZING SCREENS > Application

Sepro Mineral Systems Corp.

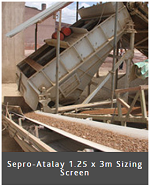

SEPRO-ATALAY SIZING SCREENS

Application:

SEPRO-ATALAY SIZING SCREENS APPLICATIONS

|

|

|

|

- Aggregates – Crushed Stone, Sand and Gravel

- Construction – Clays, Concrete and Asphalt Sands

- Coal – Sizing Hard Coal and dewatering fine Coal Slimes

- Silica Quartz and ‘Frac’ Sand

- Metallurgical – Mineral Sands and Magnetite

- Forestry – Pulp, Paper, Wood Chips and Pellets

- Recycling – Concrete, Glass, Plastic, Metal and Electronics

A truly versatile classifying solution for fine particles, the Sepro-Atalay Sizing Screen line is ideal for applications within the Mining, Industrial, Oil and Gas, Construction and Civil Works industries. The Sepro-Atalay Sizing Screen line excels in difficult fine particle separation and can be fine-tuned to meet demanding product specifications. Our Sepro-Atalay Sizing Screen line can successfully screen material previously deemed too difficult for conventional screening systems.

Controlled by a Variable Frequency Drive, the vibration needed for separation is generated by two low-powered electric vibromotors attached to the screen frame. The patented Vibro-Flex Exciter™ mechanisms are mounted directly beneath the screen deck and are used to absorb, enhance and focus all of the vibration energy directly to the screening surface and not the supporting structure. The VFE™ mechanisms create a chaotic frequency that promotes high speed particle acceleration, dynamically stratifying the material bed for efficient and effective high frequency screening.

Fine Screening is as much an art as it is a science. Simple adjustments to the angle of inclination and motor frequency can be combined with a multitude of screening media options to further customize a Sepro-Atalay Sizing Screen to your exact separation specifications.

Featured Products