Beka-Lube Products Inc

BEKA WIND

Central lubrication for wind converters

Wind converters are subject to high mechanical loads. They have to work with absolute reliability. Break down due to lack of lubrication is an avoidable failure. A central lubrication system continuously supplies fresh lubricant to the connected lub points. The right quantity at the right time. That's why a reliable lubricant supply of a wind converter can only be realized with automatic lubrication systems. BEKAwind - customized lubrication systems for each type of wind converter.

The design of BEKAwind central lubrication systems is adapted individually to each wind converter and its operating conditions. All important components like bearings, toothings and adjustment devices are supplied with precisely metered quantities of lubricant at the right time. BEKAwind central lubrication systems offer highest operational reliability and low lubricant consumption. BEKAwind central lubrication systems consist of tried-and-tested components which are used in many other industrial areas all over the world. The label BEKA is a synonym for more than 75 years of experience with lubrication.

Application

To supply all lubrication points of wind converters, such as

• Blade bearings

• Generator bearings

• Yaw bearings

• Drive pinions

BEKAwind Central Lubrication System for Wind Converters

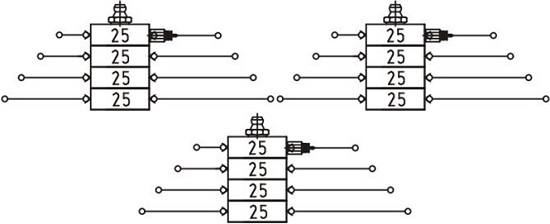

The first step towards central lubrication:

Summary of the lub points of each blade bearing

The lub points of each blade bearing are collected with a progressive distributor.

With this first step towards automatic lubrication no lub point will be forgotten.

An optical indicator signalizes the ending of a lubrication cycle.

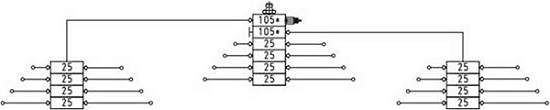

The second step towards central lubrication:

Summary to one lub point

The progressive distributors of the 3 blade bearings are collected to a so-called „one nipple system“. All lub points are supplied reliably by only one grease nipple. The grease nipple can be installed at a central point of the hub. An optical indicator signalizes the ending of a lubrication cycle.

Example of application:

Blade bearing with progressive system

consisting of progressive distributor, polyamide tubes, grease nipples and lubricant collectors.

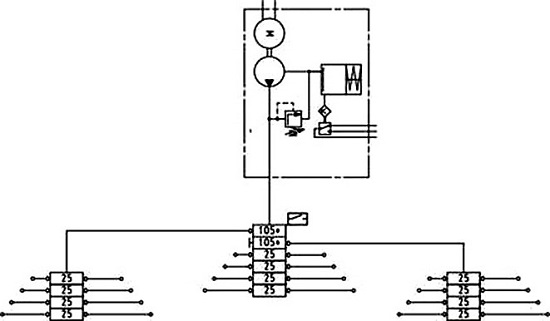

The third step towards central lubrication:

The fully-automatic central lubrication

The example shows a progressive system for 3 blade bearings with each 8 lub points.

The system consists of the following components:

• an electric piston pump EP-1R

• a progressive main distributor with 10 outlets

which is monitored by a proximity switch

• 2 progressive distributors with each 8 outlets

and the necessary fittings.

The lubrication system is controlled by the central controller of the wind converter. The lubricating pump is operated as long as the main distributor has passed the necessary number of cycles. The number of cycles and the monitoring of the distributor is made by a proximity switch which is integrated at the main distributor.

The device is protected by a pressure relief valve with return flow to the reservoir. The lubricant level in the reservoir is monitored by a level switch.

As an option, the distributors can be equipped with blocking control to ensure the function of the lubrication system even if a lub point is blocked.

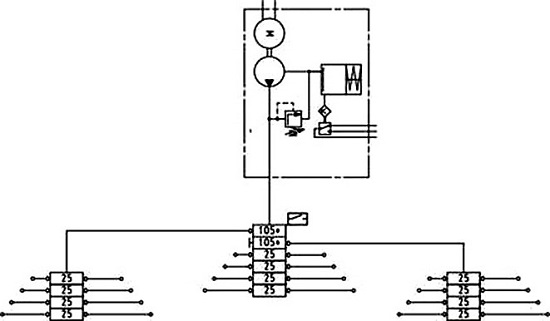

The drawing shows a BEKAwind SINGLE central lubrication system for 3 blade bearings with each 6 lub points.

The reliable and flexible lubrication system. For grease up to NLGI class 2. Easy monitoring. High operational reliability with blocking control. Application: Main bearings, blade bearings, yaw bearings.

For special lubricants with high solids contents. Very efficient, non-contacting technology. Lubrication even during intermeshing. Clean alternative to conventional gear lubrication