Beka-Lube Products Inc

BEKA FLUILUBE

Wheel flange lubrication and rail head maintenance systems

Wheel flange lubrication and rail head maintenance systems

With rail vehicles, wear on the wheels and the rail itself is a major problem together with the noise generated.

FluiLube wheel flange lubrication systems reduce the wear of rail and wheel as well as the noise load in curves in a very efficient way. FluiLube wheel flange lubrication systems offer innovative technology with tried-and-tested components and best cost-benefit-ratio.

The application of a FluiLube system using thixotropic lubricating media with high solids content represents the solution to these problems.

The FluiLube wheel flange lubrication is desighned as single line system. There are no moving parts except the pump. This means: Little wear, little maintenance requirements and therefore low life-cycle costs.

The FluiLube system corresponds to statndard DIN EN 50 155 and 61 373.

Application

1. Wheel Flange Lubrication

1. Wheel Flange Lubrication

For all rail vehicles, light rail or heavy rail, such a:

• Streetcars

• Underground trains

• Trains

• Cranes

2. Industrial lubrication

2. Industrial lubrication

Minimal lubrication for anti-friction bearings and bearing seals, such a:

• Rolling Mill Stands

• Skin Passings

• Roller Tables

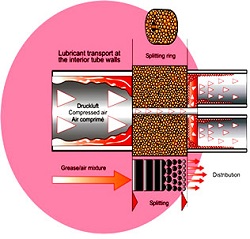

The Fluilube Procedure

The Fluilube Procedure

Compressed air transports the lubricant along the interior tube walls to the lub point. The special mixing distributor divides the lubricant precisely to the different lub pints.

Spray nozzles slightly moisten the wheel flange with a highly adhesive lubricating film, which is transferred to the following wheels by the contact with the rails and which cannot be thrown off even with very high speed. The whole process is controlled by an electronic control or the control unit of the vehicle.

Innovative wheel flange lubricants with high solids content guarantee a reliable lubrication even with extreme temperature variations. This reduces noise and wear - proven by many applications!

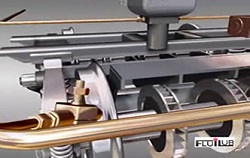

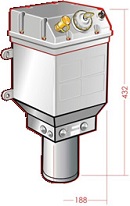

The Fluilube Pump

The Fluilube Pump

• Extremely rugged pneumatic pump, homologated according to DIN EN 50 155 and DIN EN 61 373

• Aluminium container

• Standard container size 5,81 and 81 (special versions possible, welded according to DIN 6700)

• Level monitoring with dipstick, optional electronic

• Steady mixing of the lubricant

• Delivery rate 0.05-1.0 cm'/pluse

• Special paint possible.

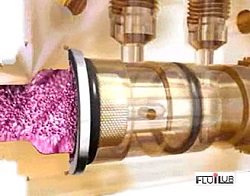

The Fluilube Pump Mixing Distributor

The Fluilube Pump Mixing Distributor

The patented splitting insert of the FluiLube mixing distributor divides the lubricant. A porous insert collects the liquid particles, splits them up to tiny droplets (0, 15mm or less) and distributes them like a drizzle to the airstream.

This principle guarantees a homogeneous mixing ratio even with several spary nozzels.

The Fluilube Spray Nozzles

The Fluilube Spray Nozzles

The FluiLube spray nozzles guarantee the lubrication of the wheel flanges even with very high velocities, without polluting other components like the brakes. The design of the spray nozzles depends on the application.

The Fluilube Сontrol Unit

The Fluilube Сontrol Unit

The FluiLube system is controlled by an electronic control unit. The compact and rugged controller allows the optimum adaption of the wheel flange lubrication to the operating conditions.

The optional curve sensor allows the curve-dependant control of the system. Conventional devices use inclination and centrifugal force, but the FluiLube sensor detects curves electronically. For even more security and rapidity.

The Fluilube Air Supply System

The air supply of the FluiLube system happens either by the pneumatic system of the vehicle or by an own compressor. All components are protected by a control cabinet.