Canadian Shield Consultants

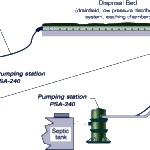

Canadian Shield Consultants offer a complete line of decentralized wastewater treatment products and services. The PSA-240 and PSA-240L pumping stations are pre-assembled and ready for plug-in. Both models are available for every possible application. Their one-piece, polyethylene construction ensures the units are watertight, eliminating the risk of seepage and infiltration.

The Effluent Filter by Premier Tech Aqua combines the principles of lamellar settling and physical filtration. This innovative solution guarentees superior treatment levels to protect the environment.

Benefits:

• Low-cost solution

• Longer life of any soil absorption system

• Higher treatment levels to protect the environment

• Quick and easy installation

• Simple maintenance

PFS-200 to PFS-1000 Pressurized Flow Dividers

Canadian Shield Consultants offers a complete line of decentralized wastewater treatment products and services. The PFS-200 to PFS-1000 pressurized flow dividers are suitable for any septic installation requiring division of effluent flow.

Description

Premier Tech Aqua’s PFS-200 to PFS-1000 Pressurized Flow Dividers divide a pumped effluent flow into equal portions, according to installation needs. They enable cluster installation of several Ecoflo® ST-650 Biofilters in high wastewater flow applications.

Operation principle

The unit divides the effluent flow using pressure generated by the pump and then distributes the effluent to the treatment units through gravity flow pipes. This way, the length of the piping systems is irrelevant. All liquid must be pumped out of the enclosure before the next dosing. If the installation design does not enable this, then measures must be taken to protect the system from freezing.

Advantages

• Division of effluent flow into equal portions;

• Low-cost solution;

• Quick and easy installation;

• Easy access to all components;

• Virtually maintenance free.

Features

• PVC and polyethylene construction;

• Operation pressure: 7 kPa (1 psi) minimum and 28 kPa (4 psi) maximum.

• 2 and 3 outlets pressurized flow dividers

• Discrepancy of less than 5%;

• Fits flexible inlet pipe, 38 mm (1.5″) inside diameter;

• PVC outlet pipe, 100 mm (4″) – dr 35, 108 mm (4.25″) outside diameter.

• 4 to 10 outlets pressurized flow dividers

• Flow discrepancy of less than 8%;

• Contained in 600 mm (24″) polyethylene casing;

• Fits flexible inlet pipe, 51 mm (2″) inside diameter;

• PVC outlet pipe, 100 mm (4″) – DR 35 outside diameter.

Operation

Installation requires nothing more than connecting the outlet end of the pumping station to the inlet of the pressurized flow divider;

Gravity outlets are connected to 100 mm (4″) PVC pipes that are connected directly to Ecoflo® ST-650 Biofilters or any soil absorption system;

The casing lid must be accessible at all times to enable annual system inspection and maintenance (or as needed).

The technology we use from Infiltrator Systems Inc. is the Equalizer 24 Chamber. This technology is the optimal choice for narrow trenches and bed applications.

Benefits

• Easy assembly and installation

• Inspection port option for easy access to leachfield, with no site disruption

• Solid-topped chambers that need no geotextile

• The Infiltrator Equalizer 24 Chamber is the number-one septic leachfield chamber system in the onsite industry. There are more than 600,000 systems installed, with over 20 million units in-ground in all 50 states and 13 countries.

During field surveys, the Infiltrator chambers system have been measurably more resistant to hydraulic failure than stone and pipe systems.

Specifications

Size (W x L x H) = 15″ x 100″ x 11″

Weight = 23 lbs.

Storage Capacity = 34 gal./4.6 ft3

Louvered Sidewall Height = 9.25″

The Polylok PL-122 Effluent Filter

Polylok’s filters are unique to the industry and are totally modular. By cutting out the designated flow panel on the back of the filter housing, the filters snap together to provide the maximum filtration possible. Polylok’s filter housing is engineered to provide years of maintence free service no matter what external forces arise during operation or service. The housing is equipped with a gass deflection/shutoff ball that not only deflects total suspended soilds from entering the filter, but it stops the flow of unfiltered effluent from escaping to the field when the filter cartridge is removed for service.

Features

• Provides double the area compared to units of similar size

• It comes with a flow control ball that shuts off the flow of effluent when the filter is removed for cleaning

• It has it’s own gas deflector ball which allows the effluent to enter the filter from the sides, deflecting the solids away

• A built in passive warning system which alerts the homeowner of potential problems months in advance as the filter matures

• Easy to install on new tanks, or retrofit in existing systems

Canadian Shield Consultants offer a complete line of decentralized wastewater treatment products and services. The PSA-240 and PSA-240L pumping stations are pre-assembled and ready for plug-in. Both models are available for every possible application. Their one-piece, polyethylene construction ensures the units are watertight, eliminating the risk of seepage and infiltration.

Description

Premier Tech Aqua’s PSA-240 Pumping Station is engineered to lift wastewater to the Ecoflo® Biofilter or any other type of septic installation. Another model, the PSA-240L, is especially designed to handle effluent from the Ecoflo® STB-650 Biofilter with Submersible Collecting Bottom.

Operating principle

Installed downstream from the septic tank, the PSA-240 pumping station sends septic tank effluent to the treatment system in controlled doses (adjusted using on/off floats). The PSA-240L is always installed downstream from the Ecoflo® Biofilter with Submersible Collecting Bottom, as close to the Biofilter as possible. Treated effluent enters the tank, where it can be pumped to either an absorption field or a tertiary treatment unit.

Advantages

• Pre-assembled and ready for plug-in;

• Lightweight, robust and durable construction;

• Easy access to internal components;

• Easy and secure access;

• Unmatched after-sales service.

Features

• Polyethylene (PE) construction;

• Audio/visual alarm system;

• 0.4 HP effluent pump;

• Weight: 40 to 46 kg (90 to 101 lb.) depending on model.

|

|

|

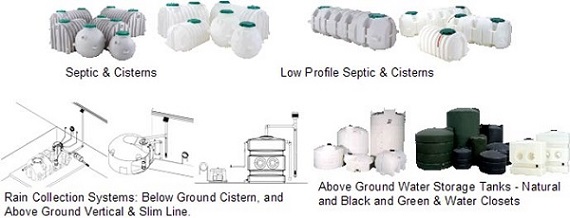

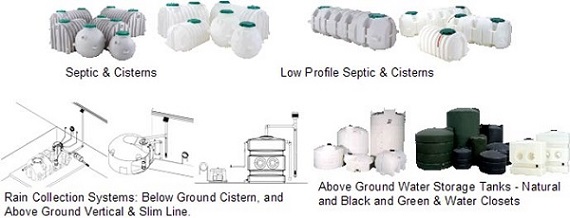

For many years, rotational molding has proven to be the ideal method of producing a seamless one-piece tank that minimizes the risk of leaking. In addition, polyethylene, because of its excellent corrosion resistance and chemical compatibility is the ideal material for on-site applications. And when properly molded, polyethylene can readily endure the stresses imposed by installation and burial loads.

At Snyder, we were not content to just develop a line of polyethylene tanks for the on-site/water markets. We developed designs to further enhance the leak proof properties of the tank(s) and improve the structure to minimize deformation of the tank(s) and maximize tank life.

The result is the best performing tanks available in the marketplace. That is why Snyder is the growing choice for on-site, water and rainwater harvesting applications.

For more than 50 years Snyder has been a leader in building plastic tanks that are lighter, stronger and more cost effective than other materials. In developing our water tank line, Snyder engineers studied the demands of each application and used computer enhanced design to strategically shape and strengthen tank walls to withstand stress.

Snyder can meet your water tank needs from five rotational molding plants. This enables faster delivery and keeps freight costs low. Most popular sizes are stocked at all locations.

From raw material analysis to stringent final inspection, the quality of Snyder’s Water Storage tanks is monitored every step of the way.

This is a high-performance polyethylene septic tank from Premier Tech Aqua, it was developed in response to the ever-growing needs of the decentralized wastewater treatment industry. Polyethylene marries lightness and easy shipping/handling to enable installation on hard-to-access sites. Thanks to it’s unique construction the high-performance septic tank is the strongest tank on the market. Its seamless design makes it air and watertight, eliminating the risk of water infiltration or leaks and minimizing odours. Its easy access for inspection and servicing ensures compliance with even he most stringent industry and government standards and requirements.

Advantages

• Air and watertight

• Lightweight, robust construction

• Easy handling and transportation

• EFT-080 Effluent Filter Casing incorporated

• Strongest tank on the market, 40% above CSA requirements

• Guaranteed leak proof, each tank is individualy tested at productin site

• Cast to allow easy installation of an EFT-080 Effluent Filter

| Model | PST-420 | PST-500 |

|

Working Capacity Total capacity Liquid level (outlet) Inlet height Length Width Height |

800 imp. gal (3600 L) 950 imp. gal 4200 38 1/2 in (978 mm) 41 3/4″ (1060 mm) 140 1/4 in (3560 mm) 49 1/4 in (1250 mm) 52 3/8″ (1330 mm) |

950 imp. gal (4300 L)

1100 imp. gal 5000 L

51 1/2 in (1310 mm)

55 3/4″ (1415 mm)

124 1/4 in (3160 mm)

49 1/4 in (1250 mm)

68 1/8″ (1730 mm)

|

Canadian Shield Consultants carry a complete line of decentralized wastewater treatment products and systems. The filter container, septic tank adapter, access risers and lid are all compatible, lightweight and easy to handle.

The TLF-240 Filter Container is especially designed to hold the EFT-080 Effluent Filter of 190 mm (7.5″) to allow safe, easy access for filter inspection and maintenance. It is also designed to serve as a sampling chamber or an acces hole. The TLF-240 should be installed as close to the septic tank as possible so that heat from the tank helps prevent freezing.

The TAD-240 Septic Tank Adapter allows access to existing septic tanks. Its unique design retrofits all residential septic tanks currently on the market.

The PSR-060 and PSR-140 Risers are designed for the TAD-240 but are also compatible with the TLF-240 Filter Container and the PSA-240 Pumping Station and come in heights of 150 mm to 700 mm (6″ to 28″). The PSR-060 can also be used as an access opening for septic tanks, in which case it is cast in concrete tanks during manufacturing. The LID-240 Access Lid fits all the above components (TLF-240 Filter Container, PSR-060/140 Risers, TAD-240 Adapter and PSA-240 Pumping Station). It is lightweight, secure and easy to handle.

Advantages

TLF-240 Filter Container

• Suited for all types of installation;

• Four flat surfaces for easy pipe connection;

• Can be used as a sampling chamber an access hale;

• Easy installation and access;

• Watertight.

Features

• Polyethylene construction;

• Standard height of 1015 mm (40″) and diameter of 680 mm (26.75″);

• Capacity of 200 L (53 gal US, 44 Imp.gal./d);

• One-piece design.

Advantages

• PSR-060-140 Risers

• Easy to install;

• Corrosion-resistant.

Features

• PSR -060

• Height of 152 mm (6″);

• Serves also as a septic tank adapter (cast in concrete tank).

• PSR – 140

• Height of 356 mm (14″)

Advantages

• TAD-240 Adapter

• Compatible with all septic tanks;

• Allows access to septic tanks.

Features

• TAD-240 Adapter

• Polyethylene construction;

• 530 mm (21″) opening

• LID-240 Access Lid

• Easy to install;

• Blends nicely with the landscape.