Schauenburg Industries Ltd.

Fans & Fan Silencers

The Fan Silencers have been developed over the years by improving on a basic concept. With noise reduction, strength, long lasting and ease of maintenance as criteria, our design offers the optimum in fan noise suppression.

Centre Core Section

We have strengthened the centre core section by manufacturing with expanded metal mesh. This maintains as smooth an inner surface as possible for maximum air flow with little pressure drop, but still allows the silencing medium to achieve desired properties. With the center core kept rigid, the ventilation line is not disturbed during scheduled maintenance of the silencer.

Silencing Medium

The packing consists of a fiberglass insulation selected for maximum silencing properties. We start with 6” fibreglass and compress it to 3”. This is held in by a fiberglass screen between the insulation and the expanded metal mesh.

Outer Skin

On the outer portions we have selected fiberglass to achieve the lightweight, strong, noise dampening qualities sought in fan silencers. As mentioned we design our silencers with maintenance in mind and the outer skin is flange fitted for quick removal. The silencing medium is then exposed for a complete change with the fan and the ducting kept intact by way of the centre core.

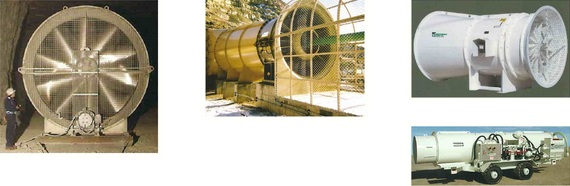

Spendrup Fan Company specializes in building customized mining fans. For 38 years, Spendrup has built thousands of mining fans that are delivering dependable, continuous operations with minimal downtime.

Tri-Metal Fans manufactures its own line of CSA-NRTL approved axial fans for hazardous and non-hazardous locations, and EMR approved axial fans for coal mine applications. Fans come in sizes up to 60 inches in diameter with air moving capacities ranging from less than one hundred cubic feet per minute to in excess of one hundred twenty thousand cubic feet.