Carriere Industrial Supply is a global manufacturer of industrial equipment and wear-parts that are engineered to outlast and outperform. We deliver innovative solutions, backed by best in class equipment management software and service. Meaning timely response to customer requirements, reliability in meeting deadlines and a value proposition appreciated by our customers. When you work with Carriere Industrial, your business prospers.

Carriere Industrial Supply is a global manufacturer of industrial equipment and wear-parts that are engineered to outlast and outperform. We deliver innovative solutions, backed by best in class equipment management software and service. Meaning timely response to customer requirements, reliability in meeting deadlines and a value proposition appreciated by our customers. When you work with Carriere Industrial, your business prospers.

Carriere Industrial Supply is a global manufacturer of industrial equipment and wear-parts that are engineered to outlast and outperform. We deliver innovative solutions, backed by best in class equipment management software and service. Meaning timely response to customer requirements, reliability in meeting deadlines and a value proposition appreciated by our customers. When you work with Carriere Industrial, your business prospers.

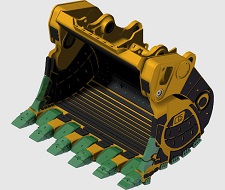

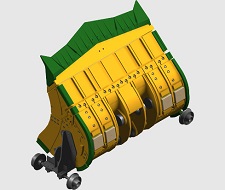

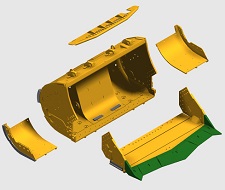

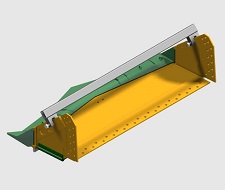

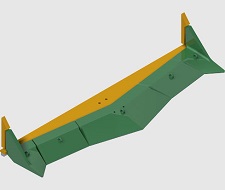

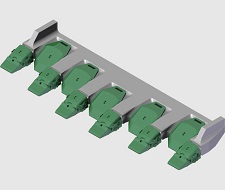

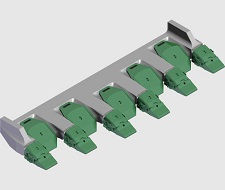

| Product Description |

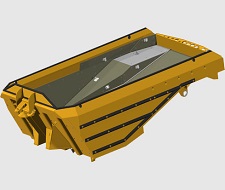

| Carriere Industrial will manufacture, upgrade or rebuild to suit your application. Our hydraulic face shovels are engineered to withstand the harshest conditions, with better productivity, greater strength and longer wear life. |

| Market Differantiator |

| With down time costing thousands of dollars per hour, Carriere Industrial specifically addresses key wear areas on the face shovel to mitigate the chance of failure and prolong the bucket wear life. Bolt on wear components on the door and clam opening can be replaced in hours as opposed days of welding on the traditional OEM design. Wear components are placed in strategic areas to protect the lip, the most critical asset on the face shovel. Liner packages are also specifically designed with weight in mind to allow for maximum capacity. Custom solutions are available for many Face Shovels available on the market. |

| Application |

|

| Related Case Studies |

| CIS Triples the Service Life of 28 m³ Face Shovel |

|

|

|

|

|

|

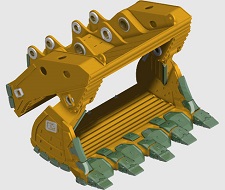

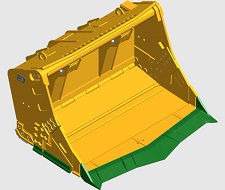

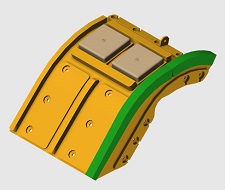

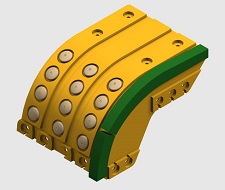

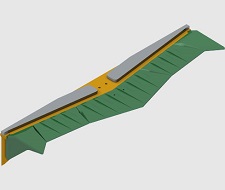

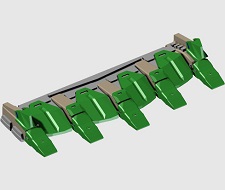

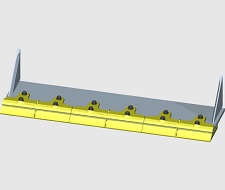

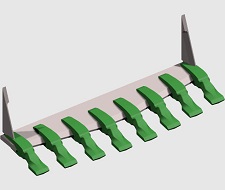

| Product Description |

| Carriere Industrial designs and manufactures bolt together LHD buckets that can be modularly assembled onsite without welding. These modular components are specifically designed to meet customer’s wear requirements and are available for most LHD models. A mechanical bucket increases bucket availability by reducing rebuild turnaround time, maintenance costs and spare buckets in the fleet. Rebuilding a bucket in less than 6 hours without any welding will reduce your overall costs and make your operation safer and more productive. |

| Market Differentiator |

| Several customer concerns lead to the development of the mechanical bucket with replaceable wear components. Today’s mines are going deeper and need increased equipment availability with minimal downtime for maintenance. Deeper mines leads to higher ventilation costs and many mines want to minimize welding underground. To increase bucket availability our design team paid attention to high wear areas of the bucket such as lips fronts, the basket area of the bucket and the spill guard. These components are produced independently from the back end bucket and are mechanically attached in a fraction of the time required than a traditional welded rebuild. The use of collet style pins and proper lubrication will allow the back end of the bucket to remain on the boom as components are changed while eliminating costly align boring and further reducing rebuild turnaround time. Mechanical components can be changed at the same time as the loader is scheduled for regular service. Other designs have been developed to ease the logistical transportation of these critical components using the mine’s current infrastructure. The elimination of costly weld repair, customized wear packages and the user-friendliness of the mechanical bucket increases LHD availability. The mechanical bucket addressed our customers’ concerns by increasing productivity through better machine availability while reducing welding and rebuild maintenance costs and the need for costly inventory of spare buckets due to shorter rebuild cycle time. |

| Application |

|

| Related Case Studies |

| Addressing Customer Bucket Issues for Underground Mines |

|

|

|

|

|

|

|

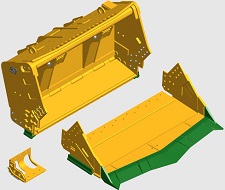

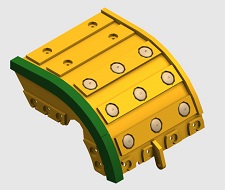

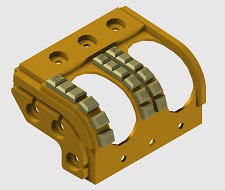

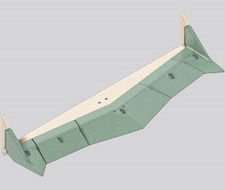

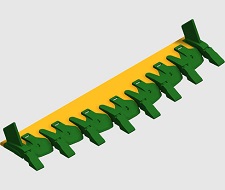

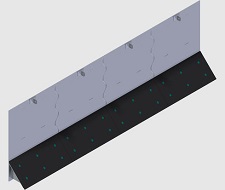

| Product Description |

| Pioneered through extensive field testing for over 15 years, Carriere Industrial designs mechanical LHD components for quick replacement and durability. The mechanical components are specifically designed based on the customer’s wear and space requirements with many different options and styles available. The use of mechanical components greatly reduces the amount of spare buckets required to operate an LHD fleet due to the quick turnaround of the bucket rebuild. No welding, higher machine availability and lower maintenance costs lead to a winning combination. |

| Market Differentiators |

| Development of replaceable wear components was done in order to address several customer concerns. Focus was placed in high wear areas such as lips fronts, the basket area of the bucket as well as the spill guard assembly of the bucket. These components are produced independently from the back end of the bucket and are mechanically attached in a fraction of the time of a traditional weld repair. Enhanced designs have been developed to ease the logistical transportation of these critical components in the mine using their existing infrastructure. This mechanical concept allows the mine to quickly load the equipment for transportation eliminating slinging of components down the shaft and a complete change out of mechanical components can now be performed by maintenance personnel in less than 6 hours at the face. |

| Application |

|

| Related Case Studies |

| Addressing Customer Bucket Issues for Underground Mines |

|

|

|

|

|

|

|

|

|

|

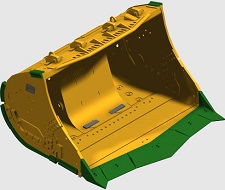

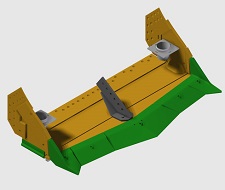

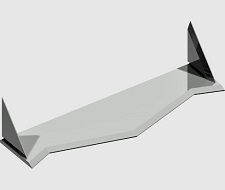

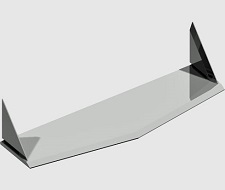

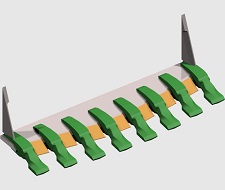

| Product Description |

| The most critical wear component of the bucket, Carriere Industrial’s welded cast LHD lip system offers the ultimate balance of penetration, durability and low weight. The time tested design allows the lip to stay continually sharp throughout its wear life while maintaining maximum payload of the bucket. Our welded cast LHD lip system will increase your loaders’ productivity and reduce your loaders operating and maintenance costs. |

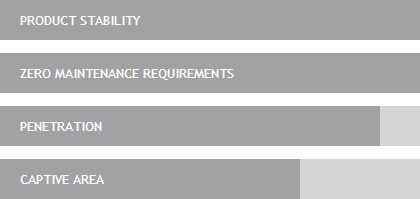

| Market Differentiator |

| Using one of the hardest cast steel alloys available on the market, the welded cast LHD lip has mucked hundreds of millions of tons of ore. The innovative welded design offers superior mucking performance compared to typically blunt bolt on lip shrouds and is a leading performer in some of mining’s most abrasive environments. To further extend the life of the lip abrasion resistant skid bars are installed to base plate to protect the back edge of the lip casting during any back blading. Superior alloy, ease of penetration, self-sharpening and ultimate durability, Carriere Industrial’s welded cast LHD lip system will increase your mine’s productivity and reduce your loaders operating and maintenance costs. |

| Application |

|

| Related Case Studies |

| Achieving Over 4 Times Wear Life of Teeth in Slag |

|

|

|

|

| Product Description |

| The most critical wear component of the bucket, Carriere Industrial offers lip systems specifically designed for use on front end loader (FEL), underground loader (LHD), excavator, hydraulic face shovel (HFS) and shovel dipper buckets. Lip systems are designed for ultimate penetration, durability and low weight based on the application required with many different styles and options available. |

| Market Differentiator |

| Carriere Industrial’s lip systems are designed for various applications and uses in the field. Our experienced technical staff will assess your specific application and specify the ideal base plate, adapter system, shroud and point style required for your equipment. In specific high wear applications such as slag, chromium carbide overlay is applied to the point in strategic areas, greatly improving wear life. Using the best alloys available and unique hammerless retaining systems for shrouds and points, Carriere Industrial’s lip systems offers leading wear performance, lower maintenance costs and improved safety. |

| Application |

|

| Related Case Studies |

| Achieving Over 4 Times Wear Life of Teeth in Slag |

|

|

|

|

|

|

|

|

|

|

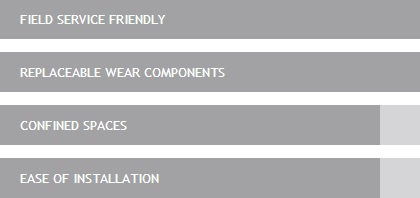

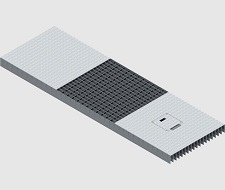

| Product Description |

| Whether on mobile or fixed assets, the appropriate wear liner material will protect the critical muck handling equipment used to move ore within the mine. Carriere Industrial’s vast experience will assist your technical and maintenance personnel in making the right decision for your operation. Along with our wear management software your operation will appreciate the increased productivity and availability of your equipment, lower maintenance downtime and ensure the long term reliability and integrity of your valued material handling assets. |

| Market Differentiator |

| Carriere Industrial is a market leader in wear liner design, supply and wear management services for the mining, aggregate and process industries. Our experienced technical staff will assess your specific wear application and specify the ideal material, thickness, grade best suited for your operations. Carriere Industrial carries a full line of heat treated plate from 400 to 600 Brinell Hardness (BHN), carbide overlay plate, rubber, rubber ceramic, epoxy ceramic, silicon carbide, UHMW and many others to meet your operations specific wear problems. Carriere Industrial will also install engineered and approved lifting lugs to ensure ease of installation and all liners are individually identified with the part number, equipment and location to facilitate installation and improve maintenance turnaround time. Using our wear liner systems along with Linerwear, a fully interactive management software tool used to monitor wear parts performance, your mining operations will realize greater productivity along with lower costs and inventories and increased asset integrity. |

| Application |

|

| Related Case Studies |

| Fine Ore Feeder High Wear Floor Liners |

| Bin Throat Liner |

|

|

|

|

|

|

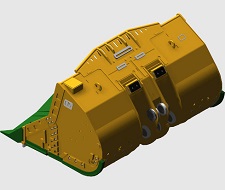

| Product Description |

| Carriere Industrial provides rock and ejector truck bodies for most OEM underground trucks. Our innovative designs are structurally reinforced in the high impact loading area to match your loading equipment and conditions and also include a customized wear liner system to meet your material characteristics. Choosing our truck bodies will increase production and reduce maintenance costs and is an investment that will outlast the life of your truck and one that will be available for use on the next one. |

| Market Differentiators |

| The design of the truck body was achieved to address several customer concerns. Our customers’ required a truck body that was designed to meet the tough application of underground mining along with increased longevity. Traditional truck bodies require major overhaul due to the structural damage incurred during loading leading sometimes to the purchase of a new truck body. Carriere Industrial truck bodies meet the challenge of today’s tough mining environment by increasing the structural strength of the body while ensuring that the design does not decrease payload. Heavy duty castings are strategically placed in critical areas of the body and the floor is reinforced structurally to mitigate impact damage in the loading zone. Bolted in liner packages are designed to reduce body floor, fender and side wall wear and carry back. These features lead to a stronger and tougher body requiring less maintenance downtime leading to lower costs. For many customers without ramp access, Carriere Industrial truck bodies are designed to be assembled underground with the greatest ease. |

| Application |

|

|

|

|

|

|

|

|

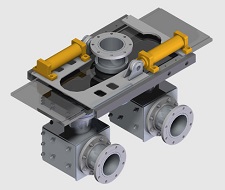

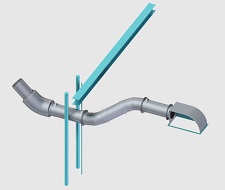

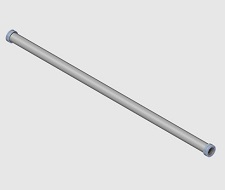

| Product Description |

| Carriere Industrial offers a complete line of mine piping solutions for hydraulic backfill, tailings and slurries applications. Depending on your operating environment pipe linings such as rubber, ceramic, poly lined (UHMW), bimetallic with weld overlay and induction hardened pipe are available to meet mining abrasive and erosion wear challenges. A complete line of hydraulic slide diverter valves for all pressure requirements are also available. Carriere Industrial will assist you making the correct material selection for your operation to ensure the best value for your specific application. |

| Market Differentiators |

| Carriere Industrial mine piping systems represent various technologies to meet mining abrasion-resistant piping requirements. There are many alternatives available, each possessing unique properties and have their distinct advantages and disadvantages. Proper selection of piping material is imperative to ensure your investment will meet your mine piping objectives. Our technical staff will assist you in your piping project and will provide the options best suited for your application. Our product line of silicon carbide, ceramic matrix, or chromium carbide welded overlay lined pipe are designed for extreme abrasion and our rubber lined product works best in fine particle wet slurries. Induction hardened pipe and bends for high wear lines are designed to meet customer non-destructive testing requirements. A complete line of hydraulic diverter valves offer easy pipe diversions during operating or emergency situations. CIS has piping available for both low pressure and high pressure requirements and can be supplied with various mechanical pipe joining systems. |

| Application |

|

|

|

|

|

|

|

|

|

|

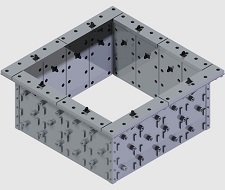

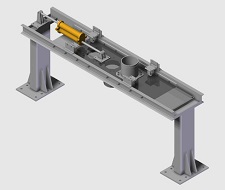

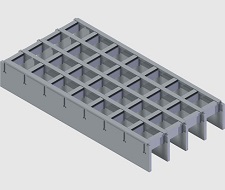

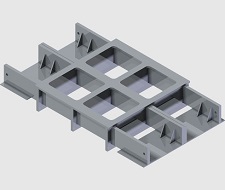

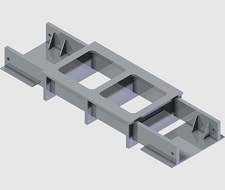

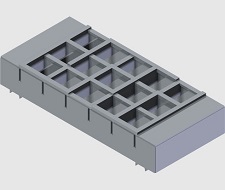

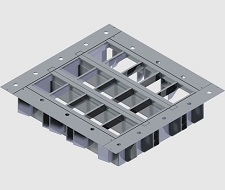

| Product Description |

| As an integral part of the muck circuit, Carriere Industrial grizzlies are designed and manufactured with longevity in mind. Custom designs meeting various applications and sizing requirements, Carriere Industrial grizzlies include easily replaceable components to limit maintenance down time. Designed and built to last, our grizzlies will provide long lasting value to your operations. |

| Market Differentiator |

| Grizzlies are used in extreme environments and need to withstand various material loading conditions and the damage caused by the hydraulic impact hammers. Carriere Industrial has improved the traditional design to relieve and reduce stresses and modified assembly design for ease of maintenance. Designed and built to the highest quality standard, and if so required for extreme conditions, grizzlies may also be heat treated to stress relieve the assembly. High impact and hardness wear bars are added to further extend the life of the grizzly. Designed and built mining tough, many customers choose Carriere Industrial grizzlies as their standard for their operations. |

| Application |

|

|

|

|

|

|

|

|

|

|

|