Tru-Flo Pumping Systems

Mining

See Mining products

| Setting The Standard |

| Quality. Dependability. Innovation. Ruggedness. These are words that embody the philosophy of the Tru-Flo Pumping Systems team.Since 1946, the Tru-Flo Vac-Assist product has stood for exceptional reliability and performance, and has continued setting the standard for premium quality and efficient pumps.Our products are engineered to be rugged, durable, and dependable. |

| Energy Efficient |

| Tru-Flo Vac-Assist Pumps are designed to deliver best in class efficiency. Depending on operating hours, fuelant, and horsepower required, you can save $3,000 per year (or more) in energy costs.The Tru-Flo Vac-Assist range of pumps offer features like no other manufacturer. Every model is designed for reliability, providing major advantages over our competitors. Built tough, these pumps will out-perform every time. |

| TRU-FLO Features & Benefits - Leading The Industry In Innovation |

| Features: |

|

• 12 month warranty • Cycloseal® • Hydraulic Balance Line • Double Volute Design • Run-Dry™ System • Redi-Prime® System • Delicate Material Handling • Various Materials of Construction • Modular Bearing Frame Design • Heavy-walled Castings • Heavy-duty Shafts • Replaceable Shaft Sleeves • Replaceable Wear Rings • Heavy Duty Bearings • Immersible Motors • Immersible Bearing Frames |

| Benefits: |

|

• Confidence in the product • No seal flush, vent line ot lubrication required • Reduction of Axial thrust plus debris flushing • Mechanical Seal protection • High Hydraulic efficiencies • Reduced product damage • Materials of construction for your application needs • Flexibility in System Design • Ruggedness • Durability • Low maintenance and repair costs • Extended service life • Easy to service; designed to run submerged • Exceptional shaft and bearing life |

| Fitted with the fastest, strongest priming system ensures rapid priming every time. This means extremely long suction lines are achievable providing unique solutions to many applications. |

| Join the ever growing list of major mining companies world wide that are finding the Tru-Flo Vac-Assist Pump the “best pumps we have”. |

|

| Innovation, Cutting-Edge Engineering and R&D |

| Tru-Flo Pumping Systems in known for innovative designs at the leading edge of technology. Many Tru-Flo innovations have evolved from our commitment to our markets and the ongoing effort to work with people in their industries to solve pumping problems. A number of unique and innovative 'firsts' have resulted from Tru-Flo's willingness and ability to adapt to changing requirements in the market. We use sound engineering practices and aggressive research and development to maintain leadership in the marketplace. Our pump designs are produced with sophisticated, state-of-the-art Compter Aided Design (CAD) and finite element analysis tools.Tru-Flo is committed to producing new designs every year to keep up with new pumping demands. We constantly strive to improve and expand our range of highly-engineered products. |

| Customer Driven Made To Order Products |

| We belive in our products and services. We work hard to develop a one-to-one relationship that will carry you through your purchase experience and continue to support your after market needs. With an eye on quality, we build products the way you want them. From stock pumps that meet your most common demands, to one-time made-to-order designs for special applications, chances are if you need it,, we can supply it. |

| Manufacturing |

| Tru-Flo Pumps are top quality, with each part machined and built to our exacting standards. Our team of exceptional machinists, craftsmen and assembly mechanics work with some of the most modern manufacturing machinery and hydraulic testing equipment in the world to bring customers a state-of-the-art product. |

|

|

|

|

|

Tru-Flo slurry pumps are recommended for pumping liquids containing small or large suspended solids. A slurry is a harsh mixture of liquid and solid particles. This combination of corrosive and erosive materials means centrifugal pumps for pumping slurries must be specially designed to resist wear and remain highly efficient. Tru-Flo can deliver a pump suitable for every slurry requirement, ranging from light duties through to the heaviest and most demanding needs. From pumping open-cut mining slurry, dredging work to pumping harsh and corrosive chemical. |

| Slurry pumps are used wherever a solid liquid combination requires pumping. |

| Typical Applications: |

|

• Coal washing plants • Mining • Oil and gas • Sand and gravel plants • Dredging for mineral sands • Ash handling facilities attached to power stations |

|

|

|

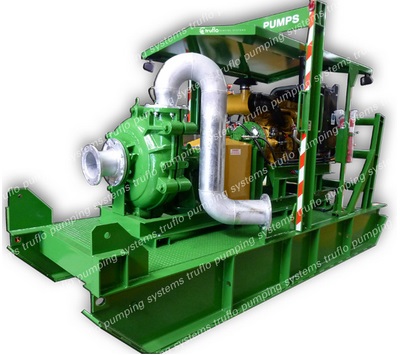

Tru-Flo Auto Prime Pumpsets are available in sound enclosed canopies or as open skid Pumpsets. Three award winning models are available in the Auto Prime range - TF30/30, TF50/30 and the TF120/25. |

| All models come standard with an 18cfm reliable compressor prime system, Tru-Flo’s renowned Cyclo Seal system, SAE close coupled and dependable Caterpillar engines. |

| The sound proof canopies are class leading at 58dba at 7m. These Pumpsets are quiet achievers providing reliable pumping solutions for contractors and councils alike in permanent and temporary pumping situations. Large lockable hinged access doors ensure easy entry into canopy for maintenance personnel when required. |

| Open skid Pumpsets include a canopy with a central lifting beam as standard to protect your asset from the elements. These skid frames are designed for all conditions including mining, civil works, contractors and hire companies. |

Sound Enclosed Flyer 2013 (pdf) Sound Enclosed Flyer 2013 (pdf) |

|

|

|

|

|

|

TF 30/30 Data Sheet TF 30/30 Data Sheet |

TF 50/30 Data Sheet TF 50/30 Data Sheet |

TF 120/25 Data Sheet TF 120/25 Data Sheet |

| TRU-FLO continues its commitment to provide quality products, system solutions and after-sale support and service to national mining companies. |

| The TRU-FLO product has been designed to offer exacting footprint specifications, parts interchangability, flange/pipe-work compatibility and improved performance on helical rotor pumps previously installed into mine dewatering applications. |

|

| Body Components: Discharge port/end cover fabricated from stainless steel to improve corrosion and erosion resistance and longer life at the stator seal point. Suction chamber extension is fitted with a stainless steel insert at the stator seal for extended seal life in corrosive applications. All external hardware is manufactured from stainless steel. The unique split ring design improves serviceability by removing the cumbersome tie bar arrangement previously used. Flexible Shaft Joint: Having no wearing parts and without the need for lubrication, the rotor adaptor offers high reliability and lower maintenance. This simplistic joint provides optimal serviceability. |

| Flexible Drive Shaft: The flexible drive shaft is manufactured from toughened materials and is now covered with an improved thickness of chemically inert, abrasive resistant Halar coating. |

| Heavy Duty Bearing Housing: The TRU-FLO range employs labyrinth-bearing seals at the DE and the NDE of the bearing housing to provide maximum bearing protection in the moist, corrosive and dusty environments experienced in underground mining. The pumps are fitted with tapered roller bearings, which have been selected for long life and continuous operation in the most arduous of applications. A triple greasing point system is used for the bearing housing body for bearing lubrication and at the DE and NDE labyrinths. The bearing cover is sealed with Loctite 5370 to prevent contamination of bearing lubricant through end cover joint. Bearing lubrication is a lithium based high temperature, high performance (EP) grease. |

| Rotor: All rotors are manufactures from 316+410 stainless steel for maximum corrosion and abrasion resistance. |

| Stator: TRU-FLO Natural rubber double bonded resilient synthetic stators offer maximum abrasion resistance. |

| Rotor Coating: The TRU-FLO range has increased the HCP coating from 0.25mm to 0.4mm and improved the chrome quality by using the MAHC chrome technology. This provides benefits such as extra hardness and improved frictional properties for extended life when pumping highly corrosive and abrasive liquids. |

| Shaft/Flexible Shaft Joint: Having no wearing parts and without the need for lubrication, this joint offers high reliability and simplified maintenance. The tapered joint allows removal of the bearing housing assembly without the need for dismantling the pump or disconnecting the pipe-work. |

| TRU-FLO Shaft Sleeve Sealing as Standard: The TRU-FLO range offers soft packed gland running on the unique tough, wear resistant coated shaft sleeve as standard. The shaft sealing on a helical rotor positive displacement pump is performed on the suction side, which makes this system ideally suited for high head abrasive liquid transfer. Split stainless steel gland follower (3 piece) for simplified gland packing access and maintenance. |

|

|

|

TF 082 Pump Data Sheet TF 082 Pump Data Sheet |

TF 084 Pump Data Sheet TF 084 Pump Data Sheet |

TF 088 Pump Data Sheet TF 088 Pump Data Sheet |

TF 102 Pump Data Sheet TF 102 Pump Data Sheet |

TF 103 Pump Data Sheet TF 103 Pump Data Sheet |

TF 104 Pump Data Sheet TF 104 Pump Data Sheet |

TF 106 Pump Data Sheet TF 106 Pump Data Sheet |

TF 4 Pump Data Sheet TF 4 Pump Data Sheet |

| Tru-Flo stock and distribute WILDEN Air operated diaphragm pumps. The WILDEN range of air pumps are renown for their reliability and performance. |

| Applications: |

|

• Chemical processing • Mine dewatering • Adhesives & resins • Paints & viscous liquids • Flammable and hazardous areas |

| Features: |

|

• Self Priming, dry running • Rugged construction • Metallica & Non-metallic construction • Various elastomer options • Anti-freeze/anti-stall & lube free air distribution systems |

|

| TRU-FLO PUMPS offer a complete range of hardware required for mine dust suppression. |

| This includes: |

|

• SIME Rainguns • Poly Pipe and Fittings • High Pressure Layflat Hose assemblies and fittings • Diesel Pumps • Electric Pumps • Rubber Suction Hose Assemblies |

|

|

When it comes to boosting water pressure, Tru-Flo have you covered. With many years of experience in this field, you will feel comfortable dealing with the team at Tru-Flo. |

| Water Boosting applications by Tru-Flo include: |

|

• Process Water Systems • Water Supply to drilling rigs and continues miners • Mine potable water pumping systems • Fire systems • Mine outbye in-line boosting • Dust suppression boosting systems • Washing and cleaning systems • Swimming baths • Seawater Systems |

|