Primero Mining Corp.

San Dimas Mine

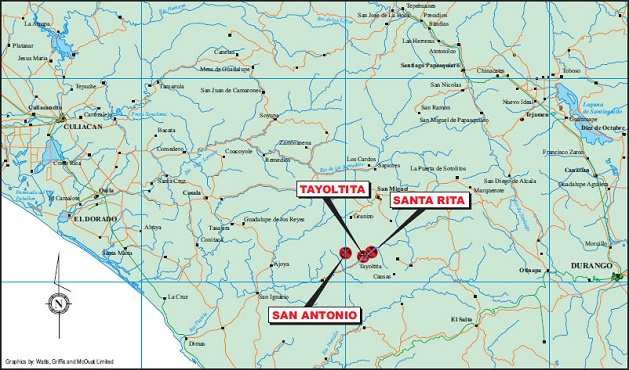

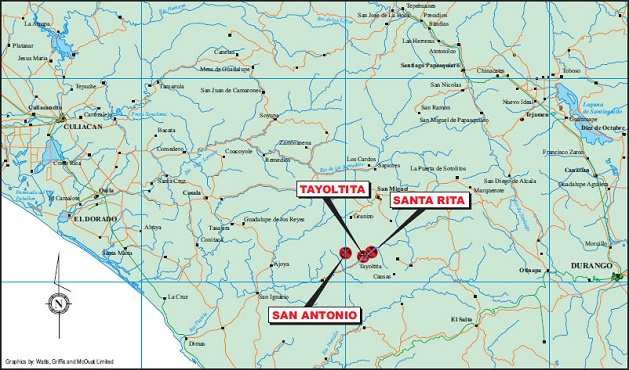

The San Dimas mine is located on the border of the States of Sinaloa and Durango, some 125 kilometres northeast of Mazatlan in central west Mexico. The site is accessed via a 45 minute flight from either Mazatlan or Durango, or by road through a ten hour drive from the city of Durango. Most of the personnel and light supplies for the San Dimas mines arrive on regular flights from Mazatlan and Durango. Heavy equipment and supplies are brought in by road from Durango.

Tayoltita is the most important population centre in the area with approximately 8,000 inhabitants, including mining company personnel. The population outside the mining town is sparse.

Water for the mining operations is obtained from wells and from the Piaxtla River. Water is also supplied by San Dimas to the town of Tayoltita from an underground thermal spring at the Santa Rita mine.

Electrical power is obtained from a combination of San Dimas owned power systems and the Federal Power Commission’s supply system. San Dimas operates hydroelectric and back-up diesel generators which are interconnected to the Federal Power Commission system.

The San Dimas region is mountainous. Elevations range from 2,400 metres on the high peaks to 400 metres in the valley floor of the Piaxtla River. Pine, juniper and scattered oak trees grow on the higher ridges while the lower slopes and valleys are covered with thick brush, cactus and grasses. Mining, subsistence farming, ranching and timber cutting are the predominant activities in the region.

San Dimas consists of five ore zones or blocks: San Antonio West, Sinaloa Graben, Central Block, Tayoltita and Arana Hanging Wall block . The San Dimas properties are surveyed and contained in a contiguous block that covers an area of 22,468 hectares. All mine production is processed through the Tayoltita mill.

All of the San Dimas mines are underground operations using mechanized cut-and-fill mining methods. After milling, cyanidation, precipitation and smelting, dore bars are poured and then transported to refineries in the United States. Over the last ten years Wheaton River and then Goldcorp invested in a major capital program that has significantly upgraded tailings management, will increase production and achieve a lower cost structure in the future.

The San Dimas gold-silver deposit is one of the most significant precious metal deposits in Mexico in a very large (15 km x 15 km) mining district. Historical production from the San Dimas district is estimated at 11 million ounces of gold and 582 million ounces of silver, affirming it as a world class epithermal mining province.

The Tayoltita mine is the oldest operating mine in the San Dimas area. The main access is a 4.4 kilometre tunnel from a portal approximately three kilometres to the northeast of the Tayoltita mill site. The Santa Rita mine main access is by adit approximately three kilometres to the northeast of the Tayoltita mill site.

Geology and Mineralization

Geology and Mineralization

The San Dimas deposit occurs in the central part of the Sierra Madre Occidental volcanic pile which contains rocks reflecting two separate periods of magmatism which were active between 100-45 million years ago and 32-23 million years ago. The veins are contained within rhyolitic, andesitic and granodioritic rocks of the older magmatic episode.

Regionally, the geological setting at San Dimas shows two major volcanic successions and a number of intrusive events. The Eocene aged Lower Volcanic Group (LVG) is predominantly composed of andesitic and rhyolitic flows and tuffs, and is intruded by a number of bodies including the dominant Piaxtla Granite (part of the Sinaloa composite batholith).

The Tertiary aged Upper Volcanic Group (UVG) is composed of a lower andesitic horizon capped by rhyolitic ash flows and tuffs, and is separated from the LVG by an erosional and depositional unconformity. Subsequent rhyolitic and basic dykes intrude both the LVG and UVG.

Structurally, the San Dimas district lies within an area of complex normal faulting along the western edge of the Sierra Madre Occidental. Compressive forces first formed predominantly east-west and north-northeast tension gashes that were later cut by transgressive north-northwest striking slip faults. The strike-slip movements caused the development of secondary north-northeast faults, with right lateral displacement.

Locally, ore is contained in over 120 gold/silver epithermal veins characterized by low sulphidation and adularia-sericitic alteration, and formed prior to deposition of the UVG. Veins pinch and swell and commonly exhibit bifurcation, horse-tailing and cymoidal structures. The veins vary from a fraction of a centimetre in width to over 15 metres, but average 2 metres. They have been followed underground from a few metres in strike-length to more than 2 kilometres.

Mineralization is typical of epithermal vein structures with banded and drussy textures. Three major stages of veining have been recognized in the district, each containing variable amounts of mineralization. The second stage produced the bulk of the ore deposits, itself having three sub-stages characterized by distinct mineral assemblages, quartz-chlorite-adularia, quartz-rhodonite, and quartz-calcite. Sulphide minerals include pyrite, sphalerite, chalcopyrite and galena as well as lesser amounts of argentite, polybasite, stromeyerite, native silver and lectrum.

The ore deposits are typically found in what is referred to as the ‘Favourable Zone’, analogous with the boiling zones. Strike length of these Favourable Zones can exceed 2,000 metres and dip length can exceed 300 metres. Exploration generally relies on a combination of structural geology, geochemistry, and fluid inclusion studies to identify the Favourable Zone. Historical reconciliation has shown that, once the Favourable Zone is defined, over 30% of the vein material contained within the zone will be classified as ore.

Mining and Mineralization

Mining and Mineralization

Underground gold and silver mining operations are carried out at the different ore zones in the district. The operations employ underground cut-and-fill and long-hole stoping techniques, with LHD equipment feeding trucks to the mills. Primary access takes advantage of the topographic relief, with adits driven at river level to intersect the veins at depth.

The ore is transported from the mining areas to the processing plant in Tayoltita. The current operations employ approximately 1,100 people.

TAYOLTITA AREA

The Tayoltita area includes the oldest operating mine in the San Dimas area. The main access is a 4.4 kilometre tunnel from a portal approximately 400 metres northeast of the Tayoltita mill.

The mining method employs mechanized cut-and-fill mining on vein mineralization using waste rock as backfill. The veins vary from 1 to 3 metres in width and generally dip at 75-80 degrees. Production drilling is largely completed with jackleg drills depending on the vein thickness. Ore is hauled from the stoping areas using LHD equipment, then by rail haulage to surface through the main access tunnel. Tayoltita has the lowest overall operating costs and cut-off grade in the area mainly due to the efficient ore transport system.

The development of the San Luis tunnel to connect the San Antonio area to the Tayoltita area enabled the development of several additional veins of variable width dipping at 75 degrees. This area is currently being developed as an important new source of ore for Tayoltita.

ARANA HANGING WALL AREA

Main access to the Santa Rita mine is by an adit located three kilometres to the northeast of the Tayoltita mill site. The vein dip varies from sub vertical to as low as 35 degrees which allows for a room and pillar mining operation in some of the flatter lying areas. Ore is hauled by LHD equipment to either an internal shaft or directly to rail haulage on the main access tunnel. The shaft employs a double drum hoist with 2.2 tonne skips. San Dimas plans to connect the rail haulage to the Tayoltita tunnel, which will considerably reduce ore transport costs. Currently, ore is loaded at the portal for surface haulage to the Tayoltita mill.

CENTRAL BLOCK AREA

The Central Block area, currently the main mining area at San Dimas, is located 2 kilometres northwest of Tayoltita. It is linked to it by the San Luis Tunnel, which provides easy access to the area, as well as integration of support services.

Mining operations at Central Block vary according to the width of the veins, since they range from one to six metres. All are exploited by conventional cut and fill. Ore haulage is by a combination of LHD equipment and trucking.

Ore is to be transported through the San Francisco Tunnel, which was completed in the second half of 2009.

SINALOA GRABEN AREA

The Sinaloa Graben area, a recently discovered high-grade exploration area, is located 2 kilometres west of the Central Block. The tunnels that serve as the main haulage levels for the Sinaloa Graben and Center Block areas were completed during the first quarter of 2010.

Exploration results to date indicate that the Sinaloa Graben could contain higher grade mineralization than the adjacent Central Block and with larger widths. Primero is focused on increasing the known mineralization in the Sinaloa Graben, which represents the future of the San Dimas mine.

PROCESSING

Milling operations are carried out at Tayoltita. The Tayoltita mill processes ore from throughout the district and has a current throughput capacity of 2,100 tonnes per day. The mill facility is a conventional operation that employs cyanidation and zinc precipitation for recovery of gold and silver.

The Tayoltita mill has undergone a series of plant expansions over its operating life. In December 2005, crushing capacity was increased to 2,100 tonnes per day, as well as improvements to the chemical treatment / leaching area.

The Tayoltita mill employs fine crushing and single stage ball milling to achieve a fine grind before passing into the leach circuit. Leaching is completed in a series of tanks providing 72 hours of leach residence time. The pregnant solution is recovered in a CCD circuit with the gold and silver recovered from solution in a zinc precipitation circuit.

Tailing is pumped by a newly installed single stage pumping station to the tailings impoundment area in a box canyon east of the mill site. The gold and silver precipitate is refined using an induction furnace to produce 1,000 ounce gold and silver dore bars.

Source: http://www.primeromining.com/Operations/San-Dimas-Mine/Overview/default.aspx