Triple R America Group

Perfectly Clean Oil

TRIPLE R bypass oil cleaners handle the total oil contamination problem by

- Removing up to 99% of all solid contaminants ( NAS 5 or better ),

- Reducing the water concentration to less than 100 PPM, and

- Eliminating resins and oxidation products.

This unique cleaning efficiency results in a tremendous package of benefits:

-

An important reduction in erosion, fatigue, abrasive wear and wear of critical clearances, which results in:

- √ No blocking of narrow passages i.e. leading to valve malfunction.

- √ Completely reliable (servo-) valves and pumps; no more pump problems.

- Stabile oil viscosity and acidity and perfect lubricating properties.

- Increased fluid life by up to 10 years or 35.000 hrs.

- No coating and corrosion of metal surfaces and no generation of rust.

- No blocking of full flow filters when starting with cold oil (the famous Monday Disease), and 2 to 4 times extended life.

- Best possible operation of the heat exchange of the oil coolers.

These technical benefits all have a direct and important impact on the machine running costs :

- Increased machine performance, controllability, system efficiency, reliability and machine life.

- Reduced power consumption.

- Longer life for hydraulic components (pumps, valves, cylinder seals and other spare part)

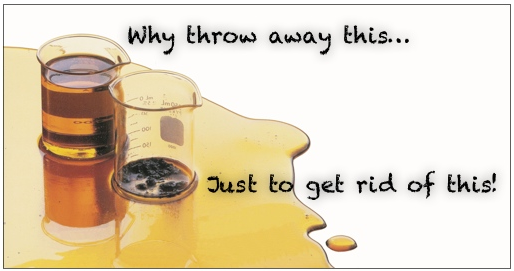

- Significant reduction of oil consumption and oil disposal cost

- An important decrease of machine down time, manpower and production loss.

- 2 to 4 times lower use of expensive full flow filter cartridges.

Conclusion

TRIPLE R turns preventive maintenance into PRO-ACTIVE MAINTENANCE.

TRIPLE R is the perfect tool to set up PRO-ACTIVE SERVICES

Source: http://www.triple-rrr.com/benefits/perfectly-clean-oil.html