3D-P Evtech Solutions Ltd

3D-P Production Load Assist

Optimize Your Load Operations with Real-Time, Accurate Payload and Center of Gravity

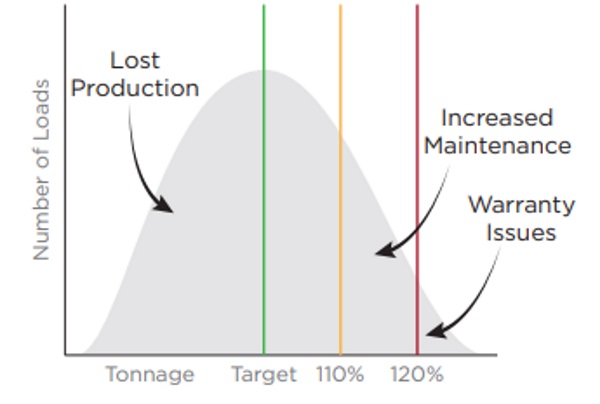

Poor machine utilization has a direct impact on productivity - under-load your truck and you are below productivity and under utilizing your assets; overload it and you risk increasing maintenance costs, tire failure, spillage and road wear.

Poor machine utilization has a direct impact on productivity - under-load your truck and you are below productivity and under utilizing your assets; overload it and you risk increasing maintenance costs, tire failure, spillage and road wear.

Poor load distribution also increases wear in your vehicle through asymmetrical stresses, increased spillage, and the resulting tire damage and required road maintenance.

The 3D-P Production Load Assist Tool enables real-time display of load pass, total tonnage, BCM, material and center of gravity data directly to both the excavator (or loader) and truck display, assisting with optimal loading of your trucks every time.

Load data is automatically collected from the truck’s on-board strut sensors, center of gravity calculated and transmitted in real-time to the excavator for immediate operator control. Tonnage/BCM data is rechecked as the truck moves off via the second gear rear-weigh, and is retransmitted to the excavator to ensure the operator receives the most correct payload value. The real-time center of gravity data enables the excavator operator to load the truck in an optimal way, ensuring that the load is as close as possible to the truck’s center of gravity, for minimized wear and tear.

Trucks automatically “pair” with the excavator based on GPS proximity and the truck’s operating state, requesting minimum effort from the operator.

|

Excavator on-board

display using the

3D-P Production

Load Assist

|

Optimal Truck Loading...

During standard truck loading, the difference between the excavator bucket and the truck payload measurements make it difficult for the operator to be 100% accurate. The second gear truck payload is also often different form the measurement at loading.

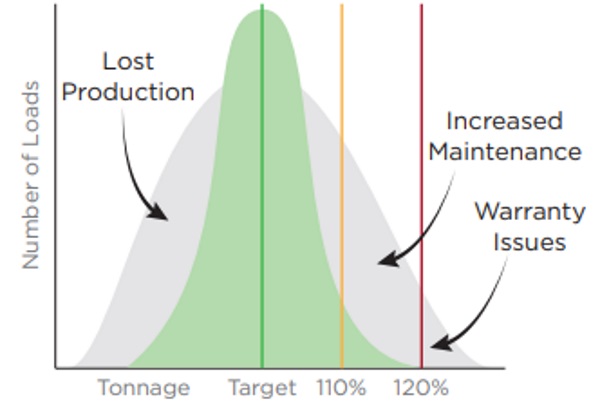

To solve this problem, the 3D-P Production Load Assist enables the accurate visualization of the load distribution and payload to bring loading significantly closer to second gear reweigh.

By implementing this enabling technology, you can increase asset utilisation or even reduce the number of assets required to achieve your production targets.

Standard Truck Loading

Optimal Truck Loading

using 3D-P Production Load Assist

...for Increased Production

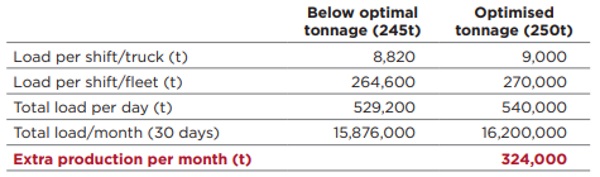

Let’s take this real-life example of a customer’s 250t truck fleet consistently under-loaded by an average of 5 tonnes (only 2%).

MINE SPECIFICS:

- 15 min load cycle (4 cycles/hr/truck)

- 2 shifts/day

- 9 hr working shift (36 loads/shift/truck)

- Fleet of 30 trucks

In this instance, the 3D-P Production Load Assist allows the mine site to produce an extra 324,000t/month.

Source: https://3d-p.com/wp-content/uploads/2018/08/3D-P-Production-Load-Assist-Product-Sheet.pdf

|

Technical Lead

The Technical Lead manages the installation of wireless network infrastructure and 3D-P proprietary Intelligent End Point solutions and third-party communication devices, and provides onsite and occasionally remote support to our existing customer base using internal best practices and business knowledge as required.

Technical Solution Advisor

3D-P’s Technical Solutions Advisor is responsible for accelerating revenue growth within the assigned region or within specific accounts, by developing, maintaining and effectively managing those customer accounts.