Orbit Garant Drilling Services

Equipment

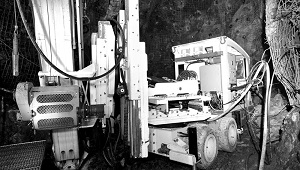

PERFORMANCE, RELIABILITY AND EXTREME ADAPTABILITY

Our ability to manufacture specialized and customized drill rigs to meet our customers’ specific needs gives us a strong competitive edge.

Soudure Royale, our manufacturing subsidiary, enables us to add value for our customers by providing optimal equipment for their needs, in addition to reduced costs and shorter turnaround times for drills and specialized equipment. We design and manufacture customized equipment that is ideally suited to the terrain and logistics of any project.

Working with our Engineering Department, we design or modify specialized equipment such as heli-portable drill rigs, and we also manufacture and supply support equipment, such as water recirculation systems, heat recovery systems, efficient fuel systems, and drill rod and core barrel handlers.

We also manufacture conventional drill rigs for third parties, which provides us with another revenue stream. Our manufacturing plant in Val-d'Or provides comprehensive maintenance services for our drills – maintaining performance quality, safety and reliability. We also stock spare parts, to reduce on-site downtime.

NEW TECHNOLOGIES

Our success rests on delivering results for our customers through innovation in drilling technology and processes. Innovation is transforming our industry – providing new tools that add new levels of value. It follows that leadership in our field over the long term – and through every stage of the cycle -- requires leadership in this area. Since the inception of Orbit Garant, we have made research and development a key priority to support our goal of continuous innovation.

Exciting breakthroughs in recent years have provided us with the opportunity to deliver new service levels. Most significant is the potential of our drill rigs with computerized monitoring and control technology. In utilizing this technology, our customers are able, in real time, to monitor our progress, view core samples, and access detailed performance reports on demand, all via the internet. From an operating standpoint, we achieve improved accuracy and consistency of results, enabling our experienced drillers to significantly increase productivity, while less experienced drillers can move faster along the learning curve compared to learning on conventional drill rigs.

In deployments on customer projects to date, we have achieved more than 30 percent greater productivity compared to conventional drilling and have reduced the duration of some customers' drilling programs by up to 50 percent. In turn, this increased efficiency means that far fewer consumables are being used and rig components are lasting longer. Each of these factors contributes to enhanced customer value, improved operating performance and strengthened competitive advantage.

Computerized control and monitoring technology is only part of the story: at Orbit Garant, we have taken innovative approaches with all the equipment we develop and utilize. For example, our team has also developed and manufactured:

- Movable surface drills equipped with rubber traction, to maximize mobility while limiting the impact on the environment;

- Large, modular, heli-portable surface drill rigs, capable of drilling to depths of 3,000 metres;

- Water recirculation and filtration systems for drilling that enable greater flexibility on project sites where water use is limited or restricted due to regulatory controls; and

- Heat exchange systems for cold climate drilling, that enable the transfer of heat from the drilling motor to the heating systems for the driller's shelter

With every advance, we see a range of benefits including greater productivity, fuel efficiency, enhanced safety features and lower environmental impact. The bottom line is better results for our customers. By staying at the forefront as an innovator, Orbit Garant is establishing leadership for the long term.

Source: https://orbitgarant.com/en/equipment/

|