MLT

FAQ

Is it more efficient to use rivets or screws with a mechanical fastener ?

A mechanical fastener with screws is faster to install. It allows a very strong clamping.

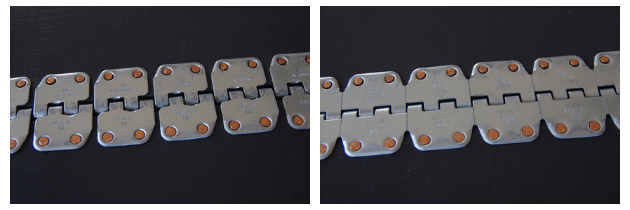

When a belt is troughed with a 30% constraint, which side of the fastener should be on top?

If a belt is troughed with a 30% constraint, the continuous face,should be on top.

This applies to rivet fasteners, Self-Lock®, Mini-Record, Record V6, les agrafes G 2000 / 2001 /2003, MS®.

"Spare" face Continuous face

Can one use a stainless steel MS® fastener with galvanized screws ?

Yes, it is possible to use galvanized screws with stainless steel MS® fasteners (if food an amagnetic qualities are not required).

Are the Super-Screw® compatible with metal detectors ?

Some Super-Screw® are available with stainless steel amagnetic screw and inserts/plates. To check the feasibility, lay some Super Screw with some screws while passing under the detector, and monitor the result of the detector.

How to prevent the connecting pins from sliding off ?

There are 2 types of connecting pins :

- Pin with a polyamide cover : after some natural wearing off, a corresponding shape of the cover at the location of the fastener loops, will prevent the sliding.

- Non coated connecting pin : both extremities can be crushed ;

Generally, when both belt sides are under tension, the sliding off is stopped.

For the rivet fasteners and the MS fasteners, connecting pins with ring and embout goupille are available.

Source: https://www.mlt-lacing.com/en-imp/frequently-asked-questions-and-experiences