Russell Industries

Gudgeon Thermfire International

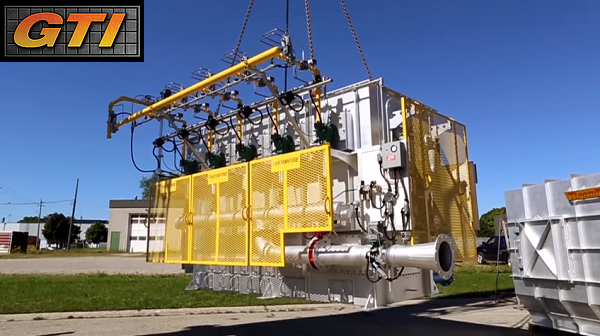

Compact, Efficient, Low N0x Gas Fired Thermal Sand Reclamation Systems

The close of WWII found a young William G. Gudgeon working as a Pattern Maker in London, Ontario, Canada. His 3 brothers, Art, Ted and Jack returned from the war and were trained for the Pattern Making trade and Gudgeon Brothers Ltd. was formed in 1949.

The boys were darn good pattern makers and they specialized in tooling for shell core and molding. As the business evolved they started to become involved with a new foundry process; chemically bonded sand molding and core making. Gudgeon Bros Ltd were appointed as the exclusive Canadian agents to promote Fordath No-Bake Foundry Equipment in the early 1960's. A relationship with Shalco Shell Core Equipment was also established to promote shell molding and core making machines.

The company was very successful and they introduced the chemically-bonded molding process from coast-to-coast in Canada capturing the continuous mixer, core making and mechanically reclamation market for over 2 decades.

The sons of William G. Gudgeon joined the Company with Brent starting in 1978 and William joining in 1982. The first generation of Gudgeon Brothers gradually retired from the company as the second generation came on-board. William Sr. remained as President until 1998.

During the 80's Gudgeon Brothers worked with Fordath's old thermal sand reclaimer It was an expensive, high maintenance machine that was in repair mode as often as it was in operation. Thermal sand reclamation was an exotic option for foundries and the Gudgeons wanted to develop a machine that was compact, unique in design with a low thermal mass, fuel efficient, easy to maintain and affordable.

Out of this ambition Thermfire was born. The Company invested in a prototype and installed it in their London plant. It was a small, stacked bed thermal reclaimer that required 3 years of development to take it from a concept to a prototype.

The jump from prototype to commercialization of the Thermfire was made in 1991 with a 3000 lb/hr thermal reclaimer sold to Cunningham Foundry in St. Catharine's, Ontario, Canada. Other orders followed and GTI Inc. learned the intricacies of building thermal reclaimers for iron, steel, aluminum and magnesium foundries that were using the entire spectrum of no-bake, chemically bonded binder systems. Today there are over 100 Thermfire systems operating all across North America, South America and India.

Since 1991 the Thermfire line of thermal reclaimers have been evolving and improving. Whether it be innovations in combustion technology, PLC controls, improved energy efficiency or boundary pushing installation concepts, GTI Inc. is the standard by which all the competitive equipment is measured.

THERMFIRE ADVANTAGE

3D CAD is mainly used for detailed engineering of 3D models and/or 2D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components. It can also be used to design objects. Furthermore many CAD applications now offer advanced rendering and animation capabilities so engineers can better visualize their product designs

All Thermfire System designs are digitized to take advantage of rapid customization of equipment clusters that support a thermal reclamation system within your plant layout. Not only will you be able to impose the selected Thermfire unit into your plant layout digitally, your will also be able to discover physical restrictions in your pouring processes in full raster animation. Feeds like power, fuel and Internet, and support equipment like shakers, conveyors and pathways to storage silos will all benefit from 3D CAD digitization before a single bolt is turned.

Source: http://www.gudgeonthermfire.ca/

Magazine

No information