Hydro Tech Inc. have successfully completed two of six thrust bearing installations

|

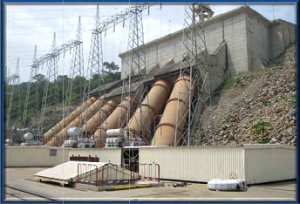

| Akosombo GS, Ghana |

Akosombo is a 6 x 170 Mega-Watt (1020 MW total) generating station that has been experiencing recurring thrust bearing damages which required frequent repairs, and in some severe cases caused bearing failure necessitating replacement of the Babbitt bearing pads. The bearing failures were attributed to turbine runner upgrades which had increased the loading on the thrust bearings. Under the increased loading, original thrust bearings were slowly deteriorating to eventual failure. Several attempts were made, by the Original Equipment Manufacturer to correct this problem by modifying various parts of the thrust bearing with only partial, temporary Akosombo GS, Ghana success followed by eventual bearing failure.

|

|

PTFE Bearing Pads, Russia

(Kenneth Arthur, Volta River Authority)

|

The thrust bearing has eighteen spring supported PTFE bearing pads. The bearing pads consist of a PTFE surface with a steel backing plate supported by a bed of precision manufactured thrust springs. The thrust runner plate is divided into four segments, which are supported by a thrust block and held in place with radial keys and eight vertical bolts holding the runner plate securely to the thrust block. The runner plate segments are tightly bolted and keyed together, then machined to provide a solid, smooth and polished running surface. The new bearing design has reduced the operating temperature (to ambient) by approximately 25% to 30%, and increased thrust load capacity by more than 70%. The new thrust bearing supports 1132 imperial tons of thrust load.

|

|

Turbine Bearing Runner Plate, Canada

(Mike Dupuis, Hydro Tech Inc.)

|

Hydro Tech Inc. provides services for medium to large hydroelectric generating companies. Services include: thrust bearing design; maintenance programs and schedules for generators and turbines; troubleshooting specific mechanical problems or malfunctions; increasing generator/turbine efficiency and reliability; completing overhauls and repairs; and condition assessment.

Source: http://www.cbb.ca/downloads/akosombo-announcement.pdf