Derrick Separation Technology

Improved Grinding Circuits

• Increase mill capacity and production rate

• Reduce power consumption per ton

• Minimize overgrinding of valuable minerals, improving the performance of downstream processes and increasing grade and/or recovery

• Concept proven in numerous worldwide mining operations

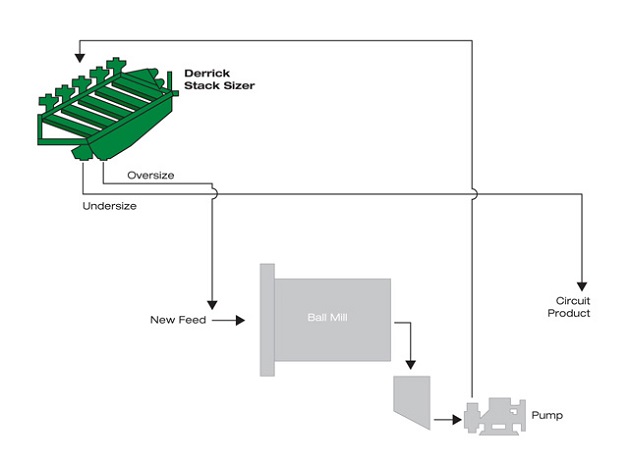

The unique combination of the high capacity Stack Sizer and fine urethane screen surfaces now makes fine wet screening a practical reality. Many mineral processing operations have taken advantage of this new technology to increase the efficiency of their grinding circuits. Replacing hydrocyclones with Stack Sizers can result in increased mill capacity and production rates, reducing power consumption per ton. Improved classification also minimizes overgrinding of valuable minerals, improving the performance of downstream processes. In many cases, closing a grinding circuit with a true particle sizing device results in a shift of the grade/grind relationship such that the same grade can be obtained at a coarser grind. This has been clearly demonstrated at multiple iron ore operations in Russia and several polymetallic operations in Peru. Depending upon the actual screen panel opening, the capacity of a five-deck Stack Sizer typically can typically range from 100 to 350 t/h.

The unique combination of the high capacity Stack Sizer and fine urethane screen surfaces now makes fine wet screening a practical reality. Many mineral processing operations have taken advantage of this new technology to increase the efficiency of their grinding circuits. Replacing hydrocyclones with Stack Sizers can result in increased mill capacity and production rates, reducing power consumption per ton. Improved classification also minimizes overgrinding of valuable minerals, improving the performance of downstream processes. In many cases, closing a grinding circuit with a true particle sizing device results in a shift of the grade/grind relationship such that the same grade can be obtained at a coarser grind. This has been clearly demonstrated at multiple iron ore operations in Russia and several polymetallic operations in Peru. Depending upon the actual screen panel opening, the capacity of a five-deck Stack Sizer typically can typically range from 100 to 350 t/h.

Closed Grinding Circuit Flow Diagram

Chromite in Turkey

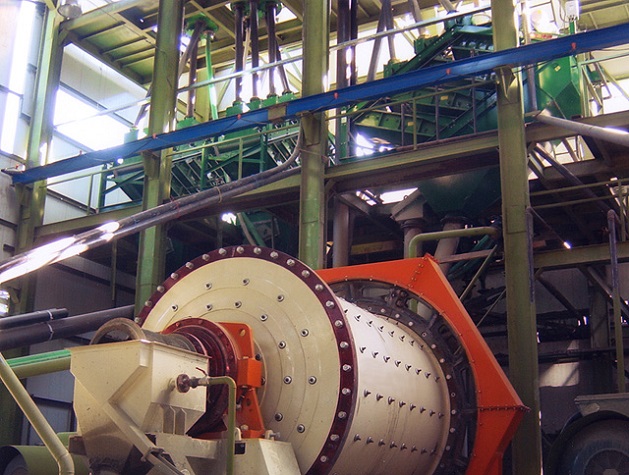

Installation in Russia

Fertilizer in Russia

Source: http://www.derrick.com/webmodules/catCatalog/dtl_Product.aspx?ID=66

|

Join Us

Derrick Corporation, the world's leading manufacturer of fine screening technology, is always looking for special people who might enhance our capabilities and improve our team. We understand that good people are the foundation for good business.