Goodwin International Limited

Installation

Best Operating Practice

To ensure that you get the best performance from your Goodwin Submersible Slurry Pump, we recommend that you follow the best practice procedures laid out on this page.

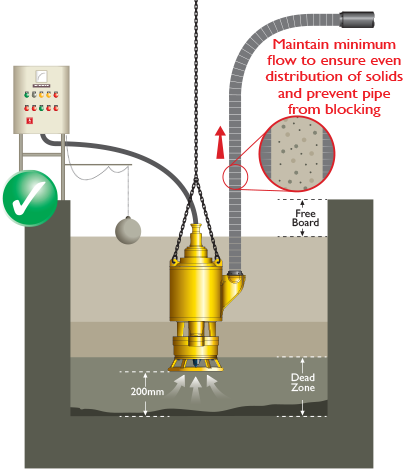

Best Installation Example

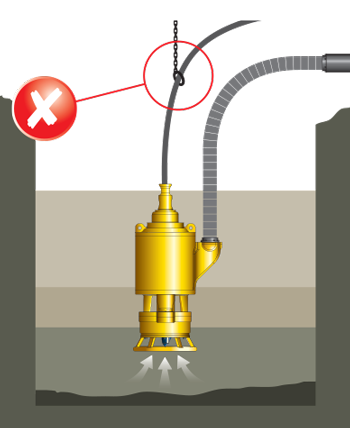

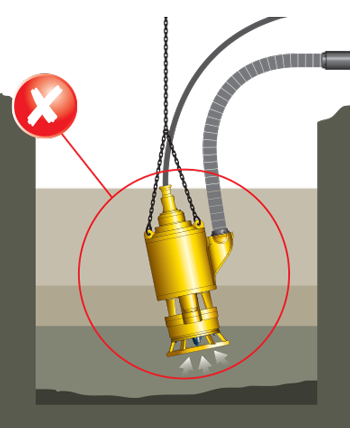

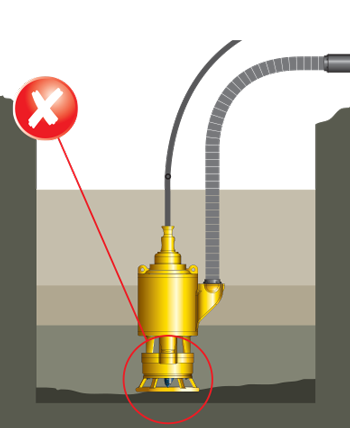

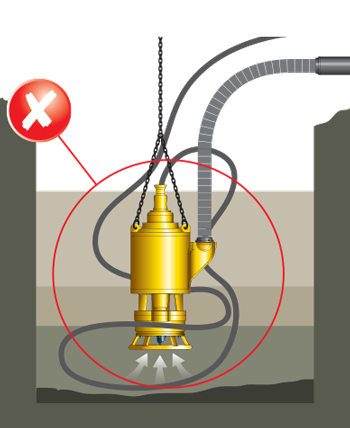

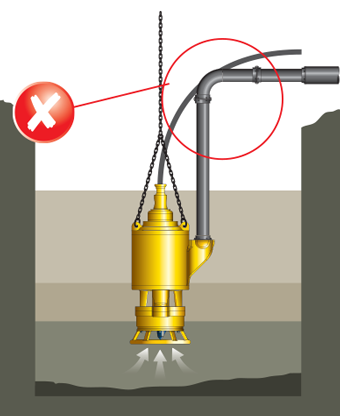

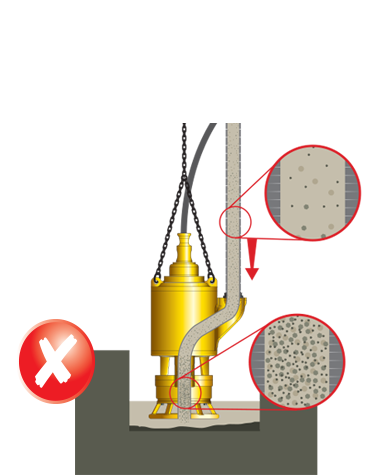

Poor Installation Examples

Correct Lifting

When moving or suspending the pump, always use certified lifting equipment. Never lift or suspend the pump using the power cable.

Vertical Positioning

For the best operation of the pump and inducer, ensure that the pump is suspended in a vertical position.

Pump Positioning

When pumping heavy slurries, always suspend the pump with the certified lifting equipment 200mm minimum above the bottom of the sump. Do not let the pump sit on the bottom of the sump.

Cable Protection

Make sure the cable can not be damaged by the rotating shaft by not allowing too much cable to be released into the slurry.

Heavy Duty Flexible Hose Usage

When pumping heavy slurries, always suspend the pump with the certified lifting equipment 200mm minimum above the bottom of the sump. Do not connect the pump directly to a rigid pipe.

Small Sumps

Small sumps lead to excessive wear and blocked pipes. The pump will quickly remove the slurry from the small sump, causing it to snore. As soon as it starts to snore, the pipe velocity reduces to zero. With no velocity in the pipe, all the heavy slurry particles settle out in the and fall back down the pipe, to the pump’s impeller. If the pump is not switched off when snoring occurs, the 'Wet-End' will wear out very quickly as it is grinding and not pumping.

- A good water to slurry ratio

- Sump level control - If the sump empties, the pump should switch itself off via the automatic control panel. The pump will switch on via a float switch or timer when the level rises.

- Pump should not exceed 20 starts per hour.

- The pump should be suspended by chains at least 200mm from base of the sump to ensure maximum concentration of solids pumped.

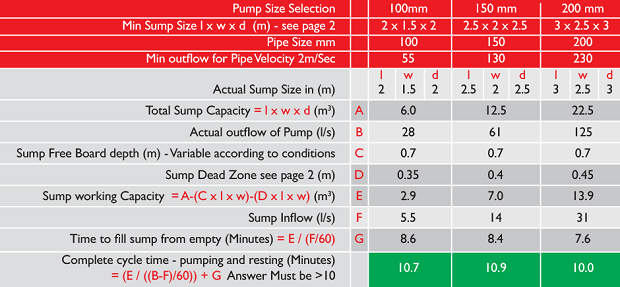

- Correct sump size - The minimum sump sizes need to be adhered to in order to obtain maximum life from the pump parts and to prevent pipeline blockages. Sump sizes are calculated based on, and are relative to:- pump size, inflow, outflow, sump working capacity and a maximum of 20 pump Stop/Starts permitted in 1 hour.

Example of how to size a sump

*If assistance is needed for sump sizing, please contact your local representative

Power Supply & Servicing

Always ensure that the pump is correctly connected and protected by using the Goodwin Fully Automatic Control System which has Earth Fault Leakage Protection.

The pump should be inspected as per the recommendations in the operating and maintenance manual.

Source: https://www.goodwininternational.co.uk/pumps/en/installation

Magazine

No information