IAMGOLD purchases the participation royalty from Barrick Gold, reducing cash costs by approximately

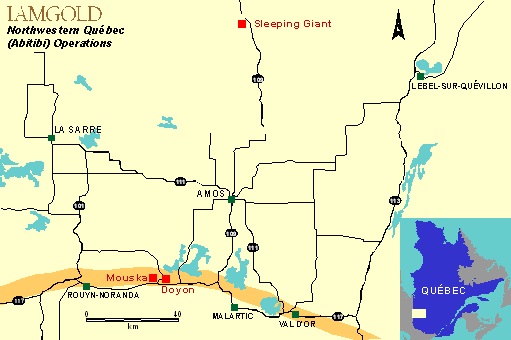

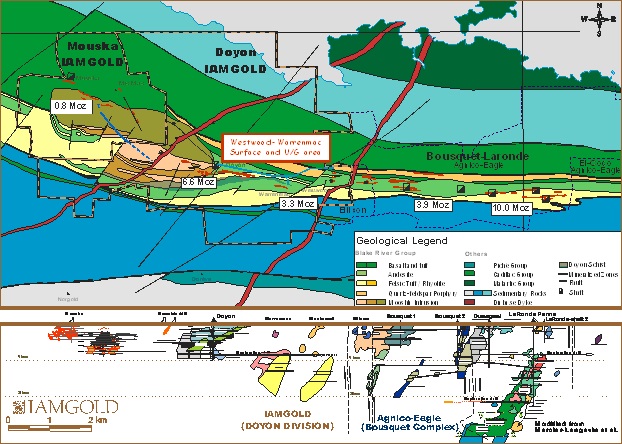

The Westwood Project is part of the Doyon-Bousquet-LaRonde (DBL) mining camp. The project is located within the southern Abitibi Sub-Province, in Archaean volcanic and intrusive rocks of the Bousquet Formation (2701-2696 Ma). The DBL mining camp hosts two world class deposits: the Doyon and LaRonde-Penna mines and is by far the largest Au-Cu-Zn-Ag producing district in Québec.

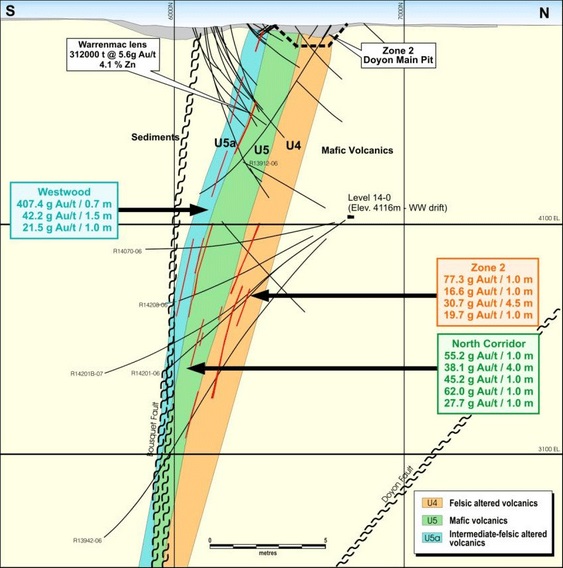

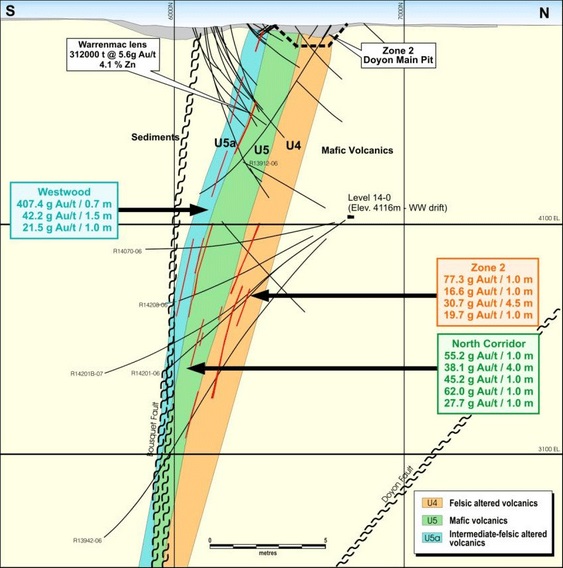

The Westwood Project area is underlain by meta-volcanics of the Blake River Group and partly by meta-sediments of the Cadillac and Kewagama Groups. Stratigraphy generally strikes east-west (100-110°), dips steeply to moderately (70-80°) towards the south and is interpreted to have a southerly facing direction. The Mooshla intrusive, a synvolcanic differentiated pluton, intrudes the volcanics in the western part of the property. Gold bearing VMS and disseminated sulphide zones occurring in the eastern part of the claims are known as the Warrenmac and Westwood showings, respectively to the west and to the east of the Bousquet Fault. Rocks hosting the Warrenmac-Westwood mineralization are lithologically and geochemically similar to the host rocks of the main sulphide lenses at the LaRonde-Penna mine. The regional foliation strikes east-west, parallel to the stratigraphy, with dips varying from sub-vertical to 70° towards the south. Regional metamorphism is transitional from greenschist to lower amphibolites facies.

Mineralization

Mineralization observed in the DBL camp is mainly associated with units #4.2, #4.3, #4.4, #5.1, and #5.2 of the Bousquet Formation. These units host gold-rich VMS-type mineralization at the Bousquet and LaRonde, deposits and gold-sulphide vein-type mineralization in Zones 1 and 2 at Doyon.

Three distinct mineralized envelopes are identified in the Westwood area. The first two zones (Zone 2 Extension and North Corridor) consist of quartz – pyrite ± chalcopyrite ± sphalerite veins and veinlets within a matrix containing 2 to 10% disseminated pyrite. The vein systems are orientated 085-095°/60-70°S, which is slightly discordant to the regional foliation in both strike and dip. These zones are located within felsic volcanic units #4.3 and #4.4, and associated with a proximal sericite-pyrite-garnet alteration assemblage.

The third envelope delineates the Warrenmac-Westwood mineralized corridor, which is located at the same stratigraphic contact on each side of the Bousquet Fault. Both consist of gold-rich pyrite-sphalerite stringers or concentrations with local massive sulphide bands (5-20cm) and minor gold-bearing sulphide-rich quartz veins/veinlets, all enveloped by a disseminated pyrite-rich alteration halo. Occasional black quartz veins with chalcopyrite traces return gold values, but not systematically. East-west sub-horizontal quartz-tourmaline (pyrite) veins are also present but rarely anomalous in gold. The Federal Government is in the final stages of an important multidisciplinary study that aims to better understand the geological and hydrothermal evolution of the DBL camp. The goal is to determine whether the Westwood mineralized zones represent a transitional system and hydrothermal link between the syn-magmatic Au-Cu veins of the Doyon deposit to the west, and the volcanogenic sulphide veins, stockworks and disseminations of the Bousquet 1 mine to the east.

Mining

Basic rock mechanics studies have been performed using data from the adjacent Doyon mine. A geotechnical drilling campaign is underway to help optimize stope dimensions, sequencing and the location of underground infrastructures. The production rate will be 2,200 tpd obtaining 200,000 ounces or 800,000 tpy in order to reach profitability. The mine start-up is scheduled for early 2013 and should be in production for at least 16 years, based on currently identified resources. The current mine plan postpones extraction of the base metal-rich zones until the end of the project to reflect the current deflated base metal prices.

Processing

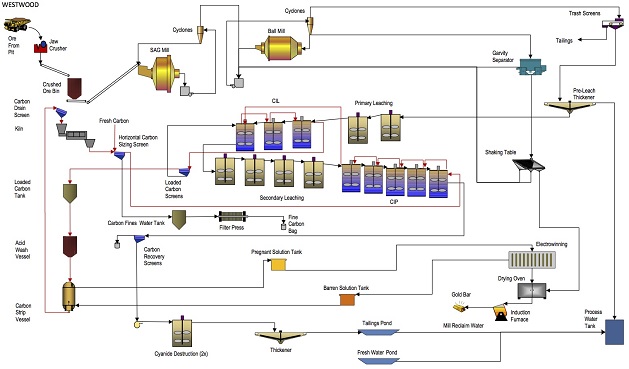

Ore processing will be carried out at the existing Doyon carbon-in-pulp (“CIP”) mill complex. However, the project will be split into two phases.

In the first phase, only the gold mineralization will be treated at the mill. During the first year of operation the Westwood mineralization will be processed at a rate of 700,000 tpa. Subsequently, the tonnage will be increased to a capacity of 800,000 tpa. The Mouska copper circuit will be temporarily converted to a desulphuration circuit. Cyanide destruction capacity will be increased to treat the generated tailings.

In the second phase, the capacity of the existing copper flotation circuit will be increased. A zinc flotation circuit will be added and a new desulphuration circuit will be set up to begin tailings reclamation.

The ore will be hauled to the Doyon mill (two kilometres away) to be crushed and ground. The ore grinding circuit will utilize the existing SAG mill and a 1,000 HP ball mill

The current Mouska flotation circuit will be used for copper flotation in the second phase of the project. Three tanks, Cell (1+2), will be added to increase the retention time and the current copper concentrate thickener (3.6 metres) will be upgraded (6 metres) in order to meet the higher demand. A new circuit will be installed for zinc flotation. The paste backfill plant will be moved closer to the Westwood shaft allowing the paste to be distributed by gravity when required by the underground infrastructure. The Doyon mill produced up to 250,000 ounces of gold per year in the 1990’s. The existing gold recovery circuit will have more capacity than required to recover the annual gold production from Westwood.