Metals & Minerals

Copper

Our copper assets in Canada consist of the Horne Smelter and the Canadian Copper Refinery (CCR), both based in the province of Quebec.

- Our CCR copper refinery in Montreal is the only copper refinery in Canada.

- The CCR refinery is conflict-free gold certified, meeting standards that show we do not cause, support or benefit unlawful armed conduct or contribute to human rights abuses.

- Horne Smelter is one of the few plants in the world that also responsibly recycles end-of-life electronics and other copper bearing materials.

Nickel

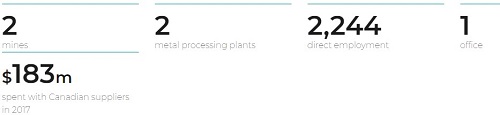

Our nickel assets in Canada consist of Raglan Mine and Sudbury Integrated Nickel Operations (Sudbury INO), based in the provinces of Quebec and Ontario, respectively.

- We have been mining nickel-copper ores in the Sudbury area of northern Ontario since 1929. Our facilities are spread throughout the 60-kilometre-long geological formation known as the Sudbury Basin.

- Our Raglan Mine is located at the extreme limit of Northern Quebec and operates some of the richest resource base-metal mines in the world.

- Raglan Mine was the first mining company in Canada to sign an Impact and Benefit Agreement (IBA) with an Indigenous population with our Raglan Agreement in 1995.

Zinc and Lead

Our zinc and lead assets in Canada consist of Bracemac-McLeod, CEZinc Refinery and General Smelting (all three based in Quebec) and Kidd Operations (based in Ontario).

- At nearly 10,000 feet, the Kidd Mine is the deepest base metal mine in the world.

- Kidd Operations was the first mine in North America to use fully automated loaders which are controlled from surface.

- The Bracemac-McLeod Mine is the 12th mine in the Matagami Camp and the camp has been in operation for more than 50 years.

Source: https://www.glencore.ca/en/What-we-do/Metals-and-minerals/Nickel

|

Sous la supervision du contremaître d’entretien électrique et instrumentation, le titulaire évoluera dans un environnement multi-métiers dans lequel il sera appelé à effectuer les tâches de technicien en électricité et en instrumentation.

Relevant du Spécialiste senior, Gestion de talent et rémunération, vous serez basé à Montréal pour supporter le recrutement pour le groupe Zinc au Canada (Services techniques Zinc, Groupe commercial, opérations et installations Zinc).

Reporting directly to Head HSEC Excellence, the HSEC Excellence Specialist provides support to HSEC Excellence Management Team.

Working at our Sudbury Operations, the successful candidate must adhere to our core values on safety performance in the workplace.

We are currently seeking a sales administrator to support our metal trading team in their daily activities. This is a full-time permanent position based in our downtown office in Toronto.

Reporting to the General Manager, the Metallurgist is responsible for developing and executing a lineup of activities aimed at improving and optimizing metallurgical processes and drafting the related procedures in order to meet company objectives and support the production department in ensuring consistency in product quality.

Reporting to the Operations General Foreman - Logistics, the Logistics Supervisor is accountable for the supervision of an underground Cage, Crusher, Tramming, material movement crew so that safety and production targets are met or exceeded.

Reporting to the Electrical Supervisor - Surface Services, you will perform the preventive maintenance and execute corrective maintenance, including the diagnosis, troubleshooting and repairs.

- Safe and efficient installation, maintenance, troubleshooting, inspection, and repair of a range of industrial machinery, electrical systems, controls and ancillary equipment;

- Supporting the operation in preventative, corrective and reactive maintenance work processes and providing feedback to optimize plant reliability

- Safe and efficient maintenance, troubleshooting, inspection, and repair of a range of traditional and sophisticated mining equipment.;

- Supporting the operation in preventative, corrective and reactive maintenance work processes and providing feedback to optimize reliability