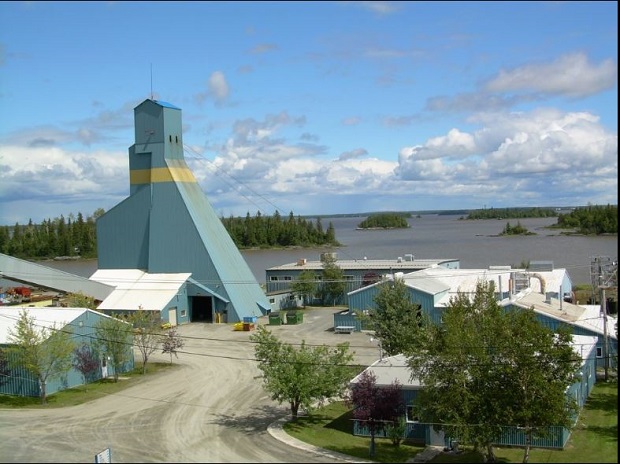

Mill Facility

Source: https://www.wesdome.com/operations/eagle-river-complex/mill-facility/

|

This position is responsible for supporting end-users primarily at our Eagle River Mine Complex.

This position is accountable for supporting accounting processes as well as the processing of accounts payable in a manner consistent with established policies and procedures.

Ensure that all buildings, and infrastructures on Wesdome property, as well as roads, culverts, & bridges are properly maintained Work in a safe, environmentally friendly, and cost-effective manner.

Heavy Equipment Mechanic is responsible, as part of a team, for maintaining the equipment and mechanical systems of the Eagle River Mine site to ensure smooth and continuous operation.

- Reporting to the Maintenance Projects, Mobile & Mine Fixed Plant Superintendent

- Ensuring compliance with health and safety and environmental regulations and policies is of primary importance with this position.

Reporting to the Eagle River Maintenance Planner or designate, the successful candidate will perform the maintenance and repairs of all surface, underground stationary equipment, long hole buggies, compressors rock breakers and pumps at the mine site.

Reporting to the Mine General Manager, the Manger of Asset Management & Reliability will be an inspirational and innovative leader responsible and accountable for operational performance excellence in the Asset Management and Reliability Department.

- The Millwright is responsible for doing the maintenance of the milling operation equipment.

- Reports to Lead hand Millwright and Mill General Foreman

The Chief Mine Geologist will be responsible and accountable for all work conducted by the Geology Department while ensuring the work is safe, cost effective and makes the most efficient use of manpower and materials.