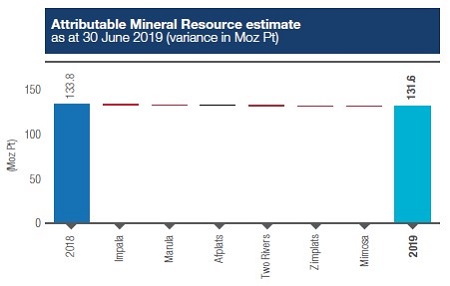

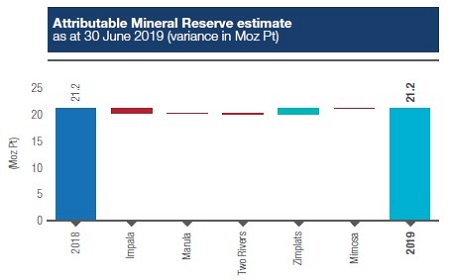

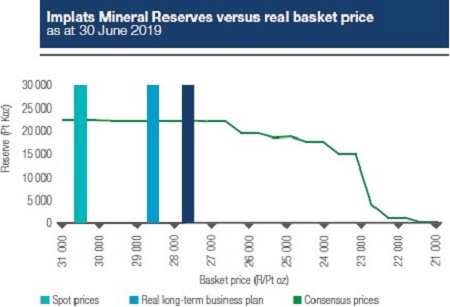

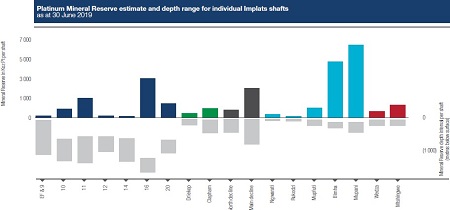

Mineral Resources and Reserves

Source: https://www.implats.co.za/mineral-resources-and-reserves.php

|

Reporting directly to the Planning/Reliability General Foreman, the Electrical Maintenance Planner is responsible for liaising between Engineering, Operations and Maintenance groups to ensure the maximum use of Maintenance resources while minimizing interruptions to Operations and Production.

Working a fourteen (14) day on fourteen (14) day off rotation at the mine site, the successful candidate will be responsible for leading and directing the Fixed Plant Maintenance Crews, while ensuring they work in a safe and productive manner at Lac des Iles Mine.

LDI mine is looking for a motivated individual to join our Safety team. Reporting to the Safety Superintendent, you will work an 8 days on / 6 days off schedule at the Lac des Iles Mine site.

Reporting to the Technical Services Manager, working a four (4) day on three (3) day off rotation or an (8) day on six (6) day off rotation at the mine site, the successful candidate will be in charge of Lac des Iles Mine’s medium to long term planning and scheduling.

Reporting to the Mill General Foreman on a 14 days on, 14 days off rotation, the successful candidate will be responsible for leading and directing the Mill Operations Crews, while ensuring they work in a safe and productive manner at Lac des Iles Mine.

- They must demonstrate the skills to prepare for long-hole blast following cleaning and loading prints, selecting blasting agents, operating loading equipment, loading holes, determining firing sequence, blasting the face and perform other duties as required and assigned by the supervisor.

- They must demonstrate the skills to operate and maintain various LHD’s on remote control, inspecting Draw-Points “Safe Limit Lines”, Remote Stands, handling oversize muck, secondary blasting and perform other duties as required and assigned by the supervisor.

- They must demonstrate the skills to operate and maintain various LHD and haul trucks and perform other duties as required and assigned by the supervisor.

- Maintain, troubleshoot, and repair all on-site mobile equipment (surface heavy equipment, underground equipment and all service vehicles).

- Service, repair and perform routine preventative maintenance on all stationary equipment on site, including hoisting and underground

- Direct and troubleshoot irregularities and malfunctions with all plant related equipment