Goodwin International Limited

Minerals Processing

Leaching

Due to the nature of many processes that are used in processing minerals and ore refining there are some extremely demanding applications found, which are ideal for the Goodwin Submersible Slurry Pump. Although our standard pump is made with a highly abrasion resistant “wet-end” and a ductile iron body for the pump, this is sometimes not suitable due to process conditions that are sometimes used in leaching.

By these “process conditions” we are referring to extremely Acidic or Alkali process media which would be totally unsuitable for the standard materials of construction. Our standard operating pH range is 4 – 10. If the pH of the slurry to be pumped is outside the standard operating range we can offer a pump constructed of suitable materials that will be resistant to the chemical attack of the pump encompassing all parts in contact with the slurry.

High Temperature Digesters

Goodwin submersible slurry pumps are utilised for pumping the processed ore slurry normally at high temperatures up to 90°C and concentrations up to 2.8 Kg / litre from digester tanks.

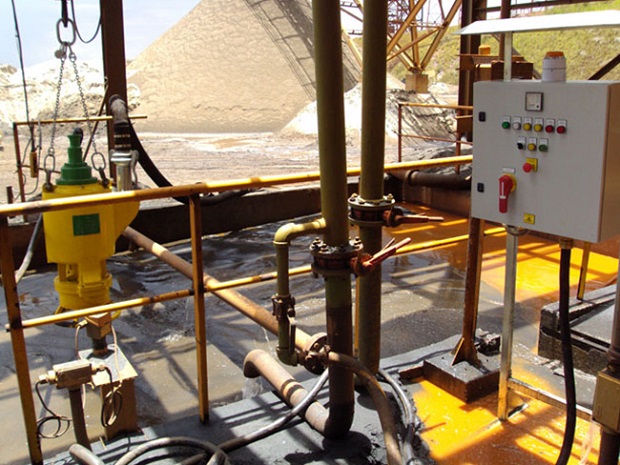

Froth Flotation Plants

For maximum effectiveness of the froth cells, there is an absolute need for good homogeneous water / solids slurry mix to feed the cells. The Goodwin submersible is used because the agitator prevents solids settling in the tank and provides consistent product to the froth cells. With the use of a bypass line and pinch valves, the flow rates can be adjusted to the requirements of the froth cells. It has been proven that the froth cells operate more efficiently with the Goodwin submersible supplying the product rather than small horizontal stationary pump units.

Cyclone Plant Centrifuge Effluent

Centrifuge Effluent is a relatively clean product to pump, but with the Goodwin Submersible installed, it is possible to combine floor clean-up sumps with the centrifuge effluent sump, negating the need for additional pumping equipment and buffer tanks or sumps. The 25-30 m3/hr of centrifuge effluent can be diverted as extra dilution into the wash down sump with good effect.

Pumps with good particle handling capabilities are needed in this application, as centrifuge baskets do fail and product up to 12 mm in size is deposited in the sump with high solids concentration.

Tailings Filter Presses

Fast filling the filter press chambers is an ideal application for the Goodwin submersible pump. It has already shown higher productivity of the presses and a saving in operating costs. The feed product to the presses is the flocculated tailings from the thickener. Without further dilution, this product is pumped from the thickener buffer tank directly to the filter press. A pressure of 3.8 bar can be generated in the filter press with the Goodwin submersible pump. When the press chambers are full, a positive displacement pump takes over to generate the higher pressure of 8 bar at which the filter cake can be discharged at 30% moisture.

The press cycle time is reduced as the press is fast filled with a higher concentration product. The positive displacement pump will run only for a fraction the time it would when fast filling with conventional pumps, so extending its operational life.

Goodwin submersible pumps supply more concentrated product to the filters and the Goodwin submersible are many times more reliable than horizontal pumps in this application as it operates with more stability over a larger portion of the characteristic curve.

Filter Press Filtrate Sumps

When filter cloths become damaged a very heavy slurry is dropped into the sump. There is a requirement for a slurry pump to be installed at this location, and this sump can be combined with floor clean-up sumps to reduce the number and type of pumps on the plant ‑ as with centrifuge effluent.

Concentrators

With ore cleaning and concentration processes they are invariably wet processes that produce large amounts of waste material that is separated from the ore. Goodwin submersible slurry pumps handle both the concentrate and waste generated, minimising water consumed and maximising efficiency by pumping slurries with up to 65% by weight concentration (2.8 kg / Litre). Because of the heavy duty nature of the Goodwin submersible slurry pump it can handle clay / silica / grit and any abrasive material that is present because of its highly abrasion resistant ‘wet end’ - handling particles up to 40mm.

There are a host of additional features that contribute to the reliability of this Submersible Slurry Pump in the most demanding environments, some of which are shown on other application examples, to see all of them please contact us so that we can send a full brochure and arrange to come and visit you.

Source: https://www.goodwininternational.co.uk/pumps/en/industry

Magazine

No information