Trinum

Mines and Metal

SELEINE SALT MINE – CHANGING THE TYPE OF BELT

LOCATION Îles-de-la-Madeleine, Québec

YEAR OF REALIZATION 2019

PROJECT TYPE OPEX

Seleine mines, a division of K+S Windsor Salt Ltd, is Quebec’s only salt mine. Over 1,300,000 tons of salt are extracted annually from underground reserves at a depth of over 400 meters. Two of the main salt conveyors have been operating with steel reinforcement belts for several years. As the maintenance for this type of belt is both difficult and expensive, the client sought to modify the equipment to be able to operate with fabric type conveyor belts.

TRINUM performed a complete audit of the conveyors. We then analyzed the tension and geometry required for the belt changes. The following modifications were made to the conveyors’ configuration:

- The two conveyors were joined to form a single conveyor.

- One of the take-up could be eliminated as well as a drive, pulleys, etc.

- The other gravity take-up was moved outward and its track was increased.

- Driving power was increased.

- Belt lifting problems at start-up were eliminated by correcting the conveyor bend radius.

- We selected for a new fabric belt

The new configuration greatly reduced maintenance work, the quantity of spare parts, etc.

DETOUR LAKE GOLD – MAGNETIC SEPARATION

LOCATION Ontario, Canada

YEAR OF REALIZATION 2020

PROJECT TYPE OPEX

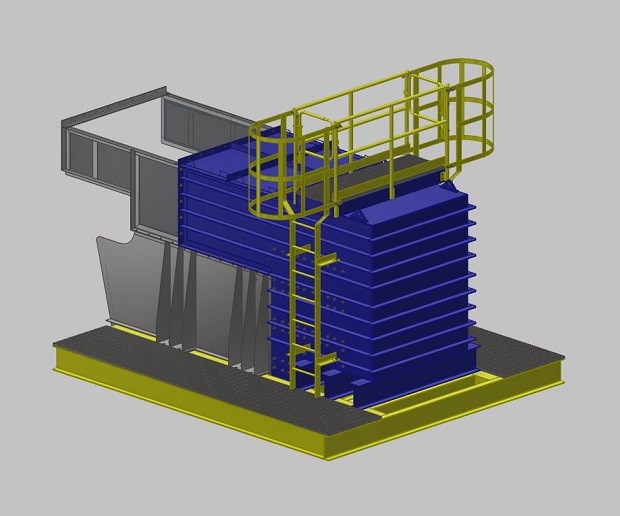

The Detour Lake open pit mine produces over 650,000 ounces of gold annually. To achieve this, more than 20 million tons of raw ore must be crushed. To avoid breakdown of various parts of the crushing and refining equipment, it is essential to remove any metal debris that could come from the mine and be transported along with the raw ore. The factory had a magnetic separator for this purpose. However, its effectiveness was considered low.

TRINUM completed an audit of the existing facilities and changed the factory configuration:

- Moving of the magnetic separator after the Apron Feeder

- Installation of a monorail

- Installation of a new debris chute

DETOUR LAKE GOLD MINE – APRON FEEDER

LOCATION Ontario, Canada

YEAR OF REALIZATION 2016

PROJECT TYPE OPEX

The Detour Lake open pit mine produces over 650,000 ounces of gold annually. To achieve this, more than 20 million tons of raw ore must be crushed. After a few years of operation, the primary crusher’s inlet chute had suffered a lot of wear and needed repair. Unfortunately, when the factory was constructed, it was not planned to build the entrance chute so that it could be replaced; it was embedded in the concrete structure of the building.

TRINUM designed a new primary entrance chute to replace the existing structure. The new chute is removable to facilitate future maintenance. We also provided a repair procedure for the damaged structure. Finally, we established the installation procedure for the new elements.

MINERAIS DE FER QUÉBEC – BELT REPLACEMENT SYSTEM

LOCATION Bloom Lake, Québec

YEAR OF REALIZATION 2019

PROJECT TYPE OPEX

After purchasing the Bloom Lake mine, Quebec Iron Ore upgraded the conveyors to improve their reliability and facilitate their maintenance. One of the critical conveyors was not designed to allow a belt change in a reasonable amount of time. In the event of a belt failure, all production would have to be shut down for over a day.

TRINUM’s mandate was to develop a method to be able to perform a belt change with minimal disruption to plant productivity. To this end, TRINUM proposed modifications to the conveyor’s structure. These changes have been implemented and detailed procedures are now available to the client’s maintenance team.

CARRIÈRES MIPO – SHIP LOADING – AGGREGATE

LOCATION Sept-Îles, Québec

YEAR OF REALIZATION 2019

PROJECT TYPE CAPEX

Our client, Les Carrières MIPO, holds the mining rights for a quarry of premium granite aggregate. The aggregates produced by this future quarry are intended for export to the southern United States. As the site is located 12 km from a major bulk port terminal, the project includes a conveyor system connecting the quarry with the port’s infrastructure.

Les Carrières MIPO commissioned TRINUM to conduct a feasibility study for the conveyor project. From the topographic surveys, we performed a complete study of the various possible conveyor routes. Preliminary quotes were also completed and presented to potential suppliers to complete a cost study. TRINUM also participated in discussions with port authorities and government agencies for permits.

CENTERA GOLD – CAPACITY INCREASE

LOCATION Prince-George, BC

YEAR OF REALIZATION 2020

PROJECT TYPE CAPEX

Centera Gold operates a large gold mine in Mount Mulligan, north of Prince George, BC. With the price of gold on the rise, the mining company sought to improve its production capacity. They wished to correct the grinding circuit, as it is a bottleneck in terms of capacity.

In collaboration with a local mining engineer, a detailed audit of the system was performed. TRINUM was commissioned to modify the sorting system of the crushing circuit to address problems such as chute blockage, spillage, dust and material accumulation. The ultimate goal is to unclog the secondary crusher and thus increase the plant’s processing capacity by 18%.

We modeled the sorting system with our specialized flow simulation software. Various solutions were investigated. Based on these digital studies, we designed a sorting and mobile chute system to better separate the different grain sizes and thus optimize crushing efficiency.

With the increase in tonnage produced by secondary crushing, the stacking conveyor at the exit was also modified to accept more material. TRINUM therefore completed the engineering required to modify the head chute and strengthen the structure.

Source: https://trinumexperts.com/en/type-realisations/mines-metal/#filter-realisations

Chargé de projet convoyeur Télétravail | Côte-Nord

- Conception de système électro-mécanique du secteur minier et forestier;

- Faire de la mise en plan ainsi que de la modélisation d'équipements de manutention avec Inventor et/ou Solidwork;

- Implanter les procédures qualité et en assurer le suivi

Dessinateur mécanique | Télétravail | Abitibi-Temiscamingue

- Faire de la mise en plan ainsi que de la modélisation d'équipements de manutention avec Inventor et/ou Solidwork;

- Conception de structure mécano-soudée et charpente métallique;

- Environnement de travail dynamique et stimulant

Dessinateur mécanique | Télétravail | Côte-Nord

- Faire de la mise en plan ainsi que de la modélisation d'équipements de manutention avec Inventor et/ou Solidwork;

- Conception de structure mécano-soudée et charpente métallique;

- Environnement de travail dynamique et stimulant

Chargé de projet convoyeur | Télétravail | Abitbi

- Conception de système électro-mécanique du secteur minier et forestier;

- Faire de la mise en plan ainsi que de la modélisation d'équipements de manutention avec Inventor et/ou Solidwork