The project remains on care and maintenance since the fall of 2017 to allow the geological team to focus its attention on the Eagle River Complex and Kiena Complex.

Unless stated otherwise, the information in this section is based upon the NI 43-101 technical report (the “Moss Lake Technical Report and PEA”) entitled “Technical Report and Preliminary Economic Assessment for the Moss Lake Project”, prepared by Sylvie Poirier, Eng., of InnovExplo, along with Pierre-Luc Richard, M.Sc., P.Geo., Julie Palich M.Sc., and Gary Patrick B.Sc. and having an effective date of May 31, 2013.

Geology and Mineralization

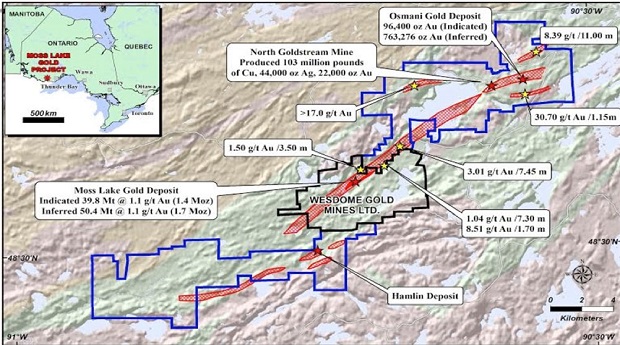

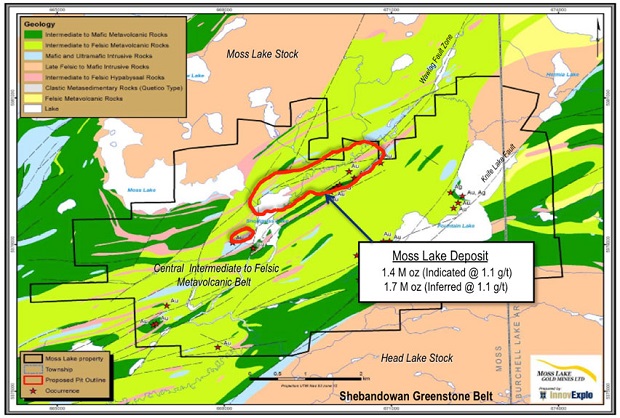

The Moss Lake property lies about 2 to 3 km southeast of the boundary between the Quetico and Wawa subprovinces, in the westernmost Ontarian part of the Wawa Subprovince. A considerable portion of the Moss Lake property is underlain by intermediate to felsic volcaniclastic rocks of the northeast-trending, fault-bounded Central Felsic to Intermediate Metavolcanic Belt (“CFB”) (Osmani, 1997), a subunit of the Shebandowan Greenstone Belt, itself part of the Wawa Subprovince of the Superior Province.

Gold mineralization in the Moss Lake deposit, between Snodgrass Lake and Span Lake, occurs in sheared intermediate to felsic metavolcanic rocks and in sheared and fractured diorite to gabbro or feldspar and quartz-feldspar porphyry bodies emplaced within intermediate to felsic metavolcanic rocks of the CFB. Gold mineralization in the Snodgrass Lake area has been described in detail by Chorlton (1987) and Harris (1970). At the Moss Lake deposit, the diorite to gabbro bodies, the quartz-feldspar and feldspar porphyries, and the felsic metavolcanics are all cut by the Snodgrass Shear Zone, a steeply dipping ductile shear zone up to 4.5 m wide and striking NE (N040) to ENE (N060-N075).

Mineralization appears as disseminated sulphides, quartz-albite veining and flooding, as well as late faulting. Alteration minerals related to mineralization consist mainly of silica, albite, sericite, carbonates, and sulphides (pyrite and minor chalcopyrite). Other alteration minerals not necessarily associated with mineralization are chlorite, hematite and epidote. Other anomalous gold values were also obtained from fractured diorite, sheared feldspar porphyry, and a moderately deformed, pink-weathering quartz-amphibole-phyric intrusion. This relatively late porphyry dyke or sill intrudes the diorite and felsic schist. In hand specimen, the quartz-amphibole-phyric intrusion is said to show a strong resemblance to the syenogranitic rocks of the Moss Lake Stock, suggesting both may be related to the same magmatic event.

Previous reports agreed that a model for the Moss Lake gold deposit implies an “intrusion-related gold deposit”. Although some authors have favoured a porphyry-style deposit, others have thought of it as a hybrid model between porphyry and more classical orogenic models.

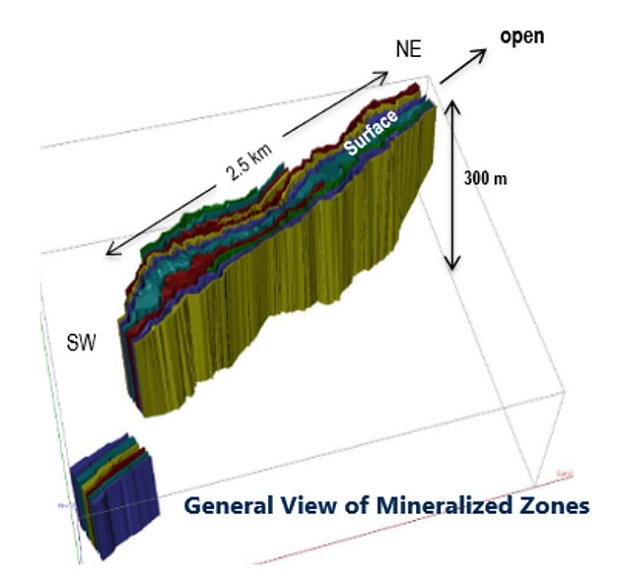

In order to conduct accurate resource modeling of the Moss Lake Project, InnovExplo constructed a mineralized-zone solid model delimiting the geologically defined extent of the mineralized zones using a 3,200-m strike-length corridor measuring 1,200 m wide and extending down to 750 m below surface. The mineralized-zone model was constructed to outline zones of continuous mineralization. Interpretation of the mineralized zones was also constrained by the presence of historical mine workings (ramp and drifts). Overall, eighteen (18) mineralized zones have been interpreted along a steep, roughly northeast trend.

3D model showing 18 mineralized zones comprising the Moss Lake deposit (looking north).

Mining Operations

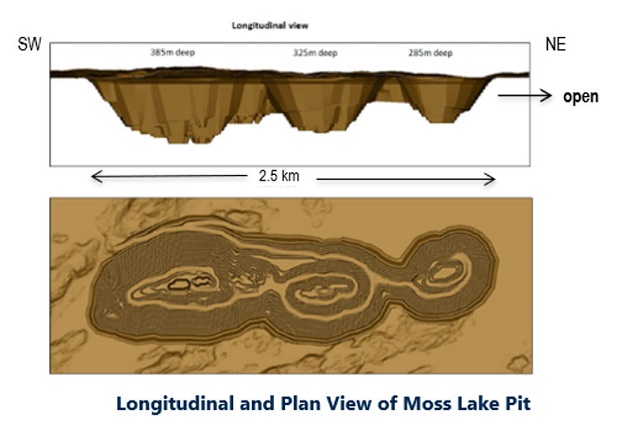

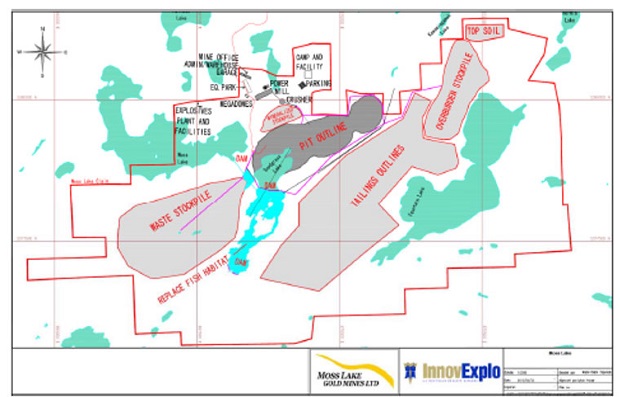

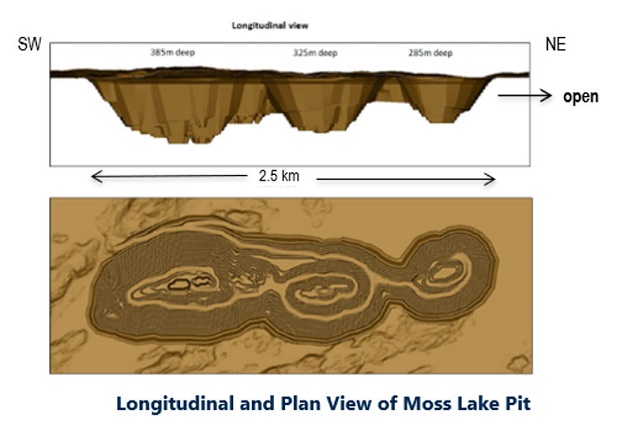

Mining of the Moss Lake deposit has been designed as an open pit with a planned production of 13,400,000 tonnes per year (13.4 million tonnes per year), or 40,000 tpd of mineralized material processed at the mill for an average of 335 days per year of mill operation and 350 days per year of mine operation.

The mine design parameters are:

-

Maximum capacity of 225 metric tonnes for off-road haul trucks;

-

10 m high mining bench;

-

Double bench at final walls;

-

Ramp gradient of 10%;

-

30 m wide ramp – double-lane traffic;

-

20 m wide ramp – single-lane traffic;

-

One-way ramp for the last two (2) permanent benches on the east side of the pit; and

-

Temporary ramp for the last two (2) benches.

Processing and Recovery Operations

The proposed Moss Lake Process Plant design is based on well-known and established Gravity/CIL technology, which consists of single stage crushing, SAG milling, ball milling, gravity recovery of free gold followed by leaching/adsorption of gravity tailings, detoxification of tailings, elution & gold smelting and tailings disposal. Services to the process plant will include reagent mixing, storage and distribution, water, and compressed air services.

Infrastructure, Permitting and Compliance Activities

New infrastructure for the Moss Lake operations will be required:

-

Crusher and mill complex;

-

Office, garage, camp and associated services buildings;

-

New electrical main line, site substation and site electrical distribution installations;

-

Pit dewatering system, surface water management and water treatment plant; and

-

Access roads to the site and on the site.

The waste stockpile will be large, covering a surface area of approximately 2.68 M m2. The overburden stockpile will be smaller than the waste stockpile. Its surface area will be approximately 1.07 M m2. Low-grade mineralized material will be transported to the stockpile to eventually be milled. The proposed stockpile will have a capacity of 15 M tonnes.

There are no protected areas within the Moss Lake Project area; the nearest protected area is the Quetico Provincial Park located 20 km west of the Property. According to regional land cover mapping, the Property is predominantly covered by wooded areas and lakes. Several low-lying areas have been mapped as wetlands around Snodgrass and Kawawiagamak Lakes and may require special consideration in any permitting and planning activities. Towards the southern property boundary, the ground cover trends more predominantly to wetlands and herbs.

The Moss Lake property comprises three named lake systems: Moss Lake, Snodgrass Lake, and Kawawiagamak Lake and several smaller open water bodies. Drainage is south into Quetico Provincial Park through a series of stream/creek and lake systems. Development of the open pit will necessitate diverting Wawiag River, which drains an upstream watershed of 143 km2, and drainage of Snodgrass Lake, which is only 2â€'4 m deep. A fish habitat replacement area, comprising 51 ha, has been incorporated into the initial project design immediately downstream of the open pit. Detailed evaluation of the hydrology, fish habitat and aquatic environment in this area will be necessary to facilitate permitting of these activities.