Frontier Lithium Inc.

Our Lithium

Our unique deposit.

Frontier Lithium is working on a rare world class low-iron spodumene deposit that is the highest grade lithium deposit known in North America.

Low Iron, high-purity technical grade spodumene.

The PAK deposit shares the differentiating characteristic of being low-iron spodumene to the world-class Greebushes’ deposit in southwestern Australia. Spodumene is the most widely used lithium mineral because of its high lithium content and occurrence.

The deposit is outcropped at the earth's surface and is amenable to low-cost open pit mining. It is an LCT (lithium- cesium- tantalum) type pegmatite (coarsely crystalline granite or other igneous rock with crystals several centimeters to several meters in length). The deposit is a large intrusion, with internal zonation (defined mineralogical assemblages) and high concentration (PAK maintains the highest known grades in North America). These types of pegmatites have been the principal source of hard rock lithium, tantalum, rubidium and cesium ores mined in the world but there are few commercially-viable deposits.

Fast Facts

- Confirmation of suitability of the material to meet the most rigorous specifications of the lithium market.

- Spodumene technical grade is the most stringent specification to meet and is the second largest market segment for global lithium demand.

- Exceeds chemical grade requirements for further upgrading to produce compounds for the lithium-ion battery market.

Approved by Global Glass Producer.

In late summer 2017 Frontier's spodumene was approved as it satisfied product criteria by a leading global consumer of high purity lithium concentrates by completion of an industrial trial as part of a 280 tonne bulk sample of the PAK lithium deposit.

As the glass and ceramics industry is the second largest market segment for lithium demand, qualifying our company and material from the deposit with a global lithium user is a very important part of our strategy for successful development. These results, in addition to the completion of the Pre-Feasibility Study currently being conducted on the project to assess the economic viability and technical feasibility of producing lithium concentrates, will provide the support to advance off-take negotiations to supply lithium products in the future.

End-users in this lithium market segment require very low impurities (mainly iron levels) in order to maintain chemical stability, consistency, and avoid discoloration of glass, glazes, and frits.

Understanding Lithium.

Lithium (chemical symbol: Li) is the lightest of all metals. It does not occur as a pure element in nature but can occur in economic concentrations in salts from surface and subsurface brines (most of the world's supply), and in granitic pegmatites in the lithium minerals (from most relevent to least) spodumene, petalite, lepidolite, and amblygonite. Spodumene is the most widely used lithium mineral because of its high lithium content and occurrence.

Lithium and its chemical compounds exhibit a broad range of beneficial properties including:

-

Thermal expansion. An extremely high coefficient of thermal expansion.

-

Catalytic characteristics. Fluxing and catalytic characteristics.

-

Viscosity modifier. Acting as a viscosity modifier in glass melts.

-

Viscosity modifier. Acting as a viscosity modifier in glass melts.

As a result, lithium is used in numerous applications that can be defined in to two categories: technical applications and chemical applications.

Technical Applications.

Lithium products (Technical-Grade Concentrates) are used directly in technical applications, particularly where lithium products with low iron concentration are necessary to meet the highly specialized requirements of end users. Frontier Lithium's deposit will enable the production of low iron lithium products suitable for technical applications. Currently, the second largest global market for lithium is for use in glass and ceramics.

1. Glass Applications

Glasses such as container glass, flat glass, pharmaceutical glass, specialty glass and fiberglass may be designed for durability or corrosion resistance or for use at high temperatures where thermal shock resistance is important. The addition of lithium increases the glass melt rate, lowers the viscosity and the melt temperature providing higher output, energy savings and moulding benefits.

2. Steel Casting Applications

The addition of lithium to continuous casting mould fluxes assists in providing thermal insulation and lubricates the surface of the steel in the continuous casting process.

3. Ceramic Applications

For ceramic bodies such as frits, glazes and heat proof ceramic cookware, lithium lowers firing temperatures and thermal expansion and increases its strength. The addition of lithium to glazes improves viscosity for coating, as well as improving the glaze’s colour, strength and lustre.

4. Iron Casting Applications

In the production of iron castings, such as engine blocks, lithium reduces the effect of veining, thereby reducing the number of defective casts.

5. Specialty Applications

Lithium’s extremely high coefficient of thermal expansion makes products such as induction cooktops and cookware resistant to thermal shock and imparts mechanical strength.

Chemical Applications.

Lithium can be processed to form a variety of chemicals, including lithium carbonate, lithium hydroxide, bromide, lithium chloride and butyl lithium. The fastest growing and now largest market for lithium globally is for use in batteries.

1. Battery Applications

Lithium is an important element in energy storage. Iron-rich chemical-grade lithium concentrates must undergo further downstream hydro-metallurgical processing (leaching and precipitation via chemical plant) to produce lithium compounds which are ultimately used in lithium batteries. Energy storage technologies fall under the category of non-stationary, as in the case of Li-ion batteries used in electronic devices such as iPAds or electric vehicles, or stationary, like those used in electric grid applications.

2. Non-Rechargable Applications

Primary batteries include the round alkaline cells used in watches and calculators and non-rechargeable AAA and AA batteries, which are used in TV remote controls, flashlights, etc. Lithium batteries have a higher energy density compared to alkaline batteries, as well as low weight and a long shelf and operating life.

3. Chargable Battery Applications

Key current applications for lithium batteries are in powering cell phones, laptops, other hand held electronic devices, power tools and large format batteries for electricity grid stabilization. The advantages of the lithium secondary battery are its higher energy density and lighter weight compared to nickel-cadmium and nickel-metal hydride batteries.

4. Lubricant Applications

lithium greases make excellent lubricants as they adhere particularly well to metal, are highly water soluble and offer consistent properties over a range of temperatures.

5. Metallurgy Applications

Lithium compounds are used as brazing and welding fluxes and as welding rod coatings, as they reduce the flux melting temperature and surface tension of steel alloys. Lithium compounds are used to degasify and clean a number of metals, including aluminum, copper and bronze (improving their electrical conductivity). Lithium carbonate is used in the aluminum industry, 1.5-4% kilograms of lithium carbonate per tonne of aluminum produced, during metal processing. The lithium lowers the melting temperature of the molten electrolyte and increases the cell's electrical conductivity, which in turn decreases processing costs, particularly energy costs.

6. Air Treatment Applications

Lithium bromide and chloride are used in air conditioners. Both compounds have high hygroscopic capacity (i.e., high water absorbing ability), and thus can reduce the moisture of the air and other gases to very low levels. As water is removed from the air, it cools, offering a refrigeration effect. Lithium-based solutions used in air conditioning applications exhibit low vapor pressure, low viscosity, high stability and non-toxic properties. Lithium bromide and lithium chloride can also be used as desiccants (humidity absorbing material) in dehumidification applications.

7. Pharmaceutical Applications

Lithium is used in the treatment for bipolar disorder as well as in other pharmaceutical products.

8. Automotive Applications

The current issues surrounding global warming, peak oil prices and petro-dictatorship have driven policies in many industrialized nations that support the development of low carbon and renewable energy technologies. At the centre of the discussion is the role of the automotive industry and its impact on the environment and resource preservation. Electrification of transportation is strongly supported by governments around the world. The introduction of mass produced passenger electric vehicles has the potential to significantly increase the future consumption of lithium. There are three main categories of electric passenger vehicles: Hybrid Electric Vehicles, Plug-in Hybrid Electric Vehicles and Electric Vehicles.

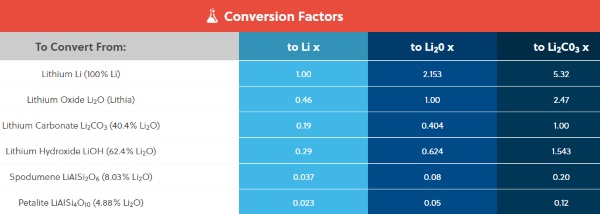

Lithium Conversion Factors.

The lithium content of minerals and compounds is referred to in 1 of 3 units depending on the source quoted and the end use referred to, including:

- Lithium (Li) content

- Lithium oxide (lithia, Li2O) content

- Lithium carbonate (Li2CO3) content or lithium

As a result, lithium is used in numerous applications that can be defined in to two categories: technical applications and chemical applications.

Source: https://www.frontierlithium.com/our-lithium.php