Trojan Tire

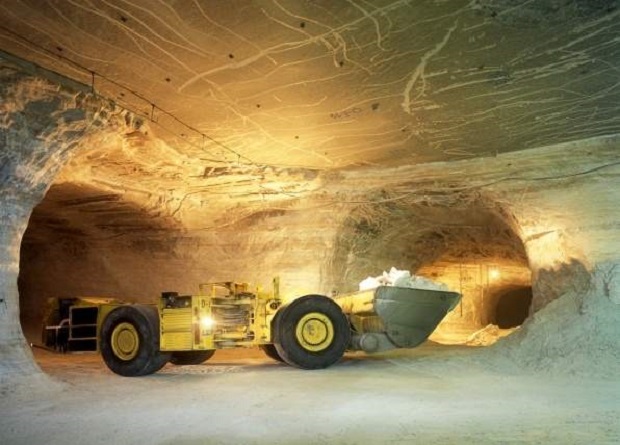

Underground Mines

Underground Potash Mine – Western Canada

Machine Type - Scoop/Loader LHD (4 yd.)

Tire Size & Type - 17.5R25 (14.00) – Radial Tire

Site Conditions - Smooth ground conditions. Machines travelling long distances and at high speeds.

Tire Problem

Mine uses the scoop as a load-and-carry vehicle. Load and carry distances up to 25km (15mi.) and high speeds up to 15 kmph (9 mph). Solid tires and polyurethane (foam) filled tires were not able to withstand the heat generated by the long runs and high speeds. Solid Tires would de-laminate and foam fill would revert to liquid. These tire problems had a significant impact on mine production and tire cost per hour.

Trojan Solution

Installed Trojan SO Soft Core in the 17.5R25 radial tire

Success / Outcome

Trojan SO Soft Core has made it possible for the mine to wear out their tires and reuse the Soft Core. The tire wear-out, Soft Core reuse and longer running hours has sharply decreased the customers tire and labor costs as well as significantly increased production. Trojan Soft Core has allowed the mine to achieve by far the lowest cost per hour versus any competing product.

Underground Hard Rock Gold Mine ‐ Central Canada

Machine Type - Scoop/Loader LHD (1.5 yd.)

Tire Size & Type - 9.50-20 (7.50) L5S Bias Tire

Site Conditions - Harsh underground mining conditions with rough floor including sharp rock debris, water and heat

Tire Problem

Site conditions often lead to cutting, penetrations and tearing. L5S bias tires with polyurethane (foam fill) were destroyed by underfoot conditions or urethane would revert to liquid due to heat and load which increased tire spend. Frequent underground tire changes incurred significant labor costs and lost production. On average a urethane filled L5S would only last 200 hours.

Trojan Solution

Installed Trojan HD Soft Core into a L5S bias tire.

Success / Outcome

Trojan Soft Core increased running hours by up to 300% per tire. This has dramatically decreased the customer tire and labor costs as well as increased production. The HD Soft Core has averaged 4 uses. This combined with the 300% increase in tire life has allowed the mine to achieve by far its lowest cost per hour versus any competing product.

Underground Coal Mine – Southeast US

Machine Type - Shuttle Car

Tire Size & Type - 14.00-20 Bias Tire

Site Conditions

Harsh underground mining condition with rough floors, steep grades, big ribs and wet conditions.

Tire Problem

Tires are up to 25% overloaded. Tires with polyurethane would start to break down and spin on the wheel, especially when on the grades. This would result in tires usually being changed with 50% tread remaining. Tires would also rib prematurely, destroying the tire and polyurethane fill.

Trojan Solution

Installed Trojan HD Soft Core in the bias tire

Success / Outcome

In most cases, the mine is now wearing out their tires. Trojan has increased the mines tire life by as much as 300-400%. Trojan has also eliminated spinning on wheels. Also, when they do rib a tire, the mine is now able to reuse the Trojan Soft Core – saving huge money!

Source: https://trojantire.com/examples/#underground-mines