Barrie Welding & Machine Ltd.

Welding and Fabrication

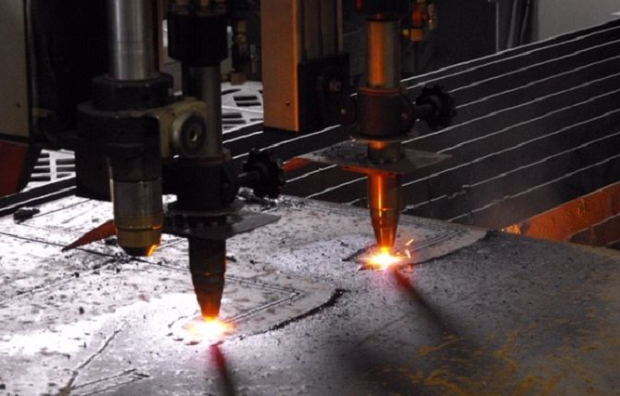

Barrie Welding & Machine (1974) Ltd is a fully equipped CWB and TSSA certified welding and fabrication shop, with years of experience in almost all industries. Serving a global customer base, our services cover everything from consumer repairs and modifications, to completely new designs, structural components, and heavy plate fabrication. Mobile welding units are also available for local projects. We have the expertise to meet your requirements in a wide variety of materials including mild steel, stainless, aluminum, cast iron, and more. Our in-house design team can even work with you to draw up a conceptual draft based on your specifications, which can then be built within our shops. Contact us today to request quotes.

WELDING PROCESSES

Our various welding processes include:

- SMAW (Shielded Metal Arc Welding)

- GMAW (Gas Metal Arc Welding)

- FCAW (Flux Cored Arc Welding)

- SAW (Submerged Arc Welding)

- GTAW (Gas Tungsten Arc Welding)

CERTIFICATIONS

Our certifications include:

- CWB W59 with qualifications under W47.1 certification of companies for fusion welding of steel and W47.2 certification of companies for fusion welding of aluminum.

- TSSA repair and alteration of boilers and pressure vessels in accordance with CSA standard B51, Power Piping ASME B31.1, Process Piping ASME B31.3, and Refrigeration Piping ASME B31.5

EQUIPMENT CAPACITY

Our equipment includes:

- Manual and CNC brake presses up to 600 ton x 16 feet long

- Laser, water jet, plasma and flame cutting up to 8″ thickness

- Plate and sheet metal rolls up to 10 feet in length

- Weld positioners up to 40,000 lbs capacity

- A variety of tank rolls up to 100 ton rating

- Over 120 overhead cranes ranging in capacity from 2 to 100 tons

Source: https://www.barriewelding.com/services/weldingfabrication

LICENSED ELECTRICIAN

- Trouble shooting and problem solving electrial issues

- Multitasking and working with attention to detail and accuracy

- Basic PLC programming

AUTOMATION ASSEMBLY DEVELOPER

- Proficient hands on build and development of automation projects for custom built weld and assembly systems

- Coordination of resources throughout all phases of automation projects to onsite commissioning of equipment on customer's floor

- Apply skilled manufacturing practices for fabrication, machining and assembly

MECHANICAL DESIGNER

- Automation and industrial machine design

- CAD software modelling and detailing