Alamos Gold Inc

Young-Davidson Mine

Ryan Clarke

General Manager

Matachewan, Ontario Canada

Young-Davidson Mine Site

Hwy 566, 3 km West of Matachewan

Matachewan, Ontario, Canada

P0K 1M0

TEL: 705-565-9800

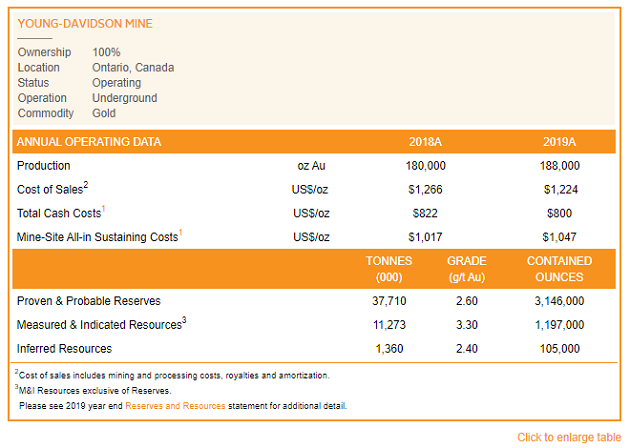

Young-Davidson is a low-cost, long-life operation and one of Canada’s largest underground gold mines. With a large Mineral Reserve base and strong ongoing free cash flow generation, Young-Davidson will serve as Alamos’ foundation for growth for many years to come.

Young-Davidson is one of our flagship operations and among Canada’s largest underground gold mines. With growing production and a large mineral reserve base, Young-Davidson is a long-life gold mine that will serve as the Company’s foundation for growth for many years to come.

OVERVIEW

Young-Davidson is a large, low-cost, bulk tonnage underground mine located in Northern Ontario. The Young-Davidson property consists of contiguous mineral leases and claims totaling approximately 11,700 acres. With a large Mineral Reserve base, Young-Davidson is a long-life operation with significant Mineral Resources and exploration potential to support mine life extension.

A multi-year expansion of the operation was completed in July 2020. The completion of this lower mine expansion has been driving production higher and operating costs lower through a number of productivity improvements. Combined with declining capital spending, this is expected to drive strong free cash flow growth going forward.

LOCATION

The Young-Davidson gold mine is located near the town of Matachewan, approximately 60 kilometres west of Kirkland Lake in Northern Ontario, within the southwestern part of the Abitibi Greenstone Belt. The mine is centrally located between Timmins, Kirkland Lake, North Bay and Sudbury and accessed by paved highway.

The Young-Davidson gold mine is located near the town of Matachewan, approximately 60 kilometres west of Kirkland Lake in Northern Ontario, within the Abitibi Greenstone Belt. Young-Davidson is centrally located between Timmins, Kirkland Lake, North Bay and Sudbury, Ontario – a region well-known for servicing the global mining industry.

HISTORY

The initial discovery of gold in the project area was made by prospector Jake Davidson in 1916 on what became the former Young-Davidson mine. This sparked a staking rush that resulted in a second discovery by Samuel Otisse on what became the MCM Mine property. Surface prospecting, trenching and outcrop stripping continued intermittently for the next several years and a joint venture was established between Hollinger Corporation and Young-Davidson Mines Limited which led to initial underground production in 1934. Between 1934 and 1957, one million ounces of gold was produced from the Young-Davidson and MCM Mine properties. Following closure of the mines, the properties remained dormant for a number of years before seeing some exploration and other activities in the 1980s and 1990s. In 2002, a private company vended the asset into Young-Davidson Mines Limited, the same company that had discovered the property, and exploration activities were re-initiated. In late 2005, Northgate Minerals amalgamated with Young-Davidson Mines Limited, and proceeded with surface exploration, environmental and engineering studies and underground exploration and development. In 2011, AuRico Gold, a predecessor of Alamos Gold, acquired Northgate Minerals which included Young-Davidson.

Open pit mining operations commenced in November 2011 and the first gold pour was achieved in April 2012. In October 2012, the first two underground stopes came into production and on October 31, 2013, the underground mine achieved commercial production following the commissioning of the shaft hoisting system. In 2015, AuRico Gold merged with Alamos Gold.

GEOLOGY AND MINERALIZATION

The Young-Davidson gold deposit, located in the southwestern Abitibi Greenstone Belt of Ontario, Canada, is a significant mineral resource hosted within a structurally complex Archean terrane. This region is renowned for its prolific gold endowment, with historical production exceeding 160 million ounces.

The deposit is characterized by gold mineralization associated with a syenite intrusion emplaced within a sequence of metamorphosed volcanic and sedimentary rocks. Gold occurs within a stockwork of quartz veinlets and narrow veins, typically less than a few centimeters in width, enveloped by a broader halo of disseminated pyrite and potassic alteration. This mineralization style is indicative of hydrothermal fluid flow associated with the syenite emplacement.

Notably, the mineralization at Young-Davidson extends to depths greater than 1,500 meters and remains open, suggesting considerable resource potential. The deposit exemplifies the role of magmatism and structural controls in generating significant gold concentrations within Archean greenstone belts.

Further investigations, including detailed petrographic and geochemical analyses, are crucial to fully understand the genesis of the deposit and optimize exploration and resource development strategies.

MINING AND PROCESSING

The Young-Davidson mine is a highly efficient, bulk tonnage gold operation designed for low-cost production. Utilizing two shafts and a ramp system, the mine accesses ore at depths reaching 1,500 meters. It employs modern, large-scale equipment and advanced mining techniques, including long hole open stoping and paste backfill, to maximize productivity. Ore extraction and transport are optimized through a system that minimizes re-handling, with scooptrams loading material directly into an ore pass system for hoisting to the surface.

A significant expansion project, completed in July 2020, transitioned the mine to a new, higher-capacity infrastructure. This state-of-the-art infrastructure boasts an 8,000 tonne per day (tpd) capacity, exceeding the previous 6,000 tpd limit, and incorporates advanced automation technologies. This upgrade has resulted in a substantial increase in gold production and a corresponding decrease in operating costs.

Ore processing is carried out through an 8,000 tpd single-stage semi-autogenous grinding circuit, followed by flotation. Gold is extracted from both the flotation concentrate and tailings using carbon-in-leach (CIL) circuits. The operation adheres to responsible environmental practices, employing the SO2/Air method for cyanide destruction in tailings.

Young-Davidson exemplifies a modern, high-throughput mining operation. Its strategic focus on technological advancement, process optimization, and environmental stewardship positions it as a leader in the gold mining industry.

Source: https://www.alamosgold.com/mines-and-projects/producing-mine/Young-Davidson/#overview

|

Development Boomtruck Operator

- Safely move material as directed. Report and document all material moved accurately to his/her Supervisor;

- Accurately report to supervisor the material needed in storage areas U/G

Rock Breaker Operator

- Operate rock-breaker;

- Perform pre-op and post-op inspections on equipment

Scissordeck Bolter

- Install ground support as per company standard;

- Install and maintain services;

- Load development rounds

Ground Control Engineer

- QAQC of shotcrete, ground support installation, grouting, ground support auditing and paste fill;

- Document inspections of underground stoping and development;

- Rock mass characterisation and classification

Mine Engineer

- Assist with blast improvement investigations;

- Look for opportunities to improve efficiencies;

- Provide guidance to EIT’s

Construction Miner - Transmixer

- Operate equipment such as transmixer and shotcrete sprayer;

- Assist in installation, modification and repairs of UG infrastructures

Geological Technician/or Junior Geologist

- 3D digitizing of underground geological mapping and integration into 3D mining software.

- Digitize geological surface geological mapping lithology, structure and mineralization

- Digitize chip sampling of ore development headings as required

Mill Operator/Labourer

- Works and ensure all workers work in compliance with the Occupational Health & Safety Act, Regulations for Mines and Mining Plants and all other applicable government standards and regulations;

- Adheres to and enforces all safety and environmental considerations

Document Control Coordinator - Phase III

- Implement document and data management solutions with a primary focus on workflow, document control, information security and records management.

- Provide ongoing training and support to end users in the use of the document management system.

- Ensure project and operations teams comply with the document management requirements and procedures

Project Controls Manager - Phase III

- Development and implementation of project controls systems and procedures.

- Working with accounting personnel to ensure accurate reporting and approval of accruals, forecasts, and project status.

- Early identification and notification of deviations and variances to project baseline schedule and spend