Continental conveyor idlers are for continuous operation, high capasities, and heavy, abrasive materials where lump size is limited by the width of the belt. Troughed belt idlers may be fumished with end rolls inclined at 20o, 35o or 45o, the latter rwo handling a volume of materials limited only by the construction of the belt.

lt is with great pleasure that Continental presents this Screw Conveyor Catalogue and Engineering Manual which covers our complete line of screw conveyors and accessories. The information compiled in this manual is the result of many years‘ experience in the design and manufacture of bulk material handling equipment and is thereby your assurance of the best in both equipment and recommendations.

With the help of this manual. the screw conveyor user is given sufficient design information with which to effectuate a sound selection of both single components and complete screw conveyors alike. All Continental screw conveyors and components are designed and built in accordance with the standards established by the industry and are therefore completely interchangeable with equipment of other recognized manufacturers.

Continental's production facilities have also kept pace with inherent advancements in design. Numerous specialty machines have been designed and methods have been devised that help assure and control manufacturing tolerances, thus providing for interchangeability of parts, greater ease of assembly, smoother operation and longer life. We sincerely hope that you will find this manual complete in detail, easy to use and extremely helpful in fulfilling your screw conveyor requirements.

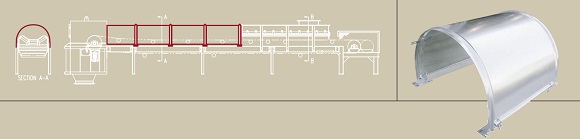

Conveyor covers are used to protect transported material and conveyor belting, idlers and structure. They effectively improve personnel safety, reduce loss of material to wind and stop grime and rain from damaging the idlers and belt. At Continental Conveyor we take pride in the manufacturing of our conveyor covers.

We focus on the entire conveyor cover solution by offering:

Our goal is to ensure that your material is protected and under cover.

Continental Conveyor & Machine Works limited have been manufacturing bulk material handling equipment to both CEMA and custom specifications in their Thetford Mines plant since 1963. The fully equipped, modern fabricating and machining facilities lend themselves well to the production of high quality, precision engineered products to serve the bulk material handling requirements of today's industry.

This catalogue is designed to aid the conveyor pulley user in selecting the proper pulley for their particular application while at the same time allowing the flexibility of the hub system of their choice, be it the CXTB, Dodge "taper lock" or a.D.

The pulleys described herein are those meeting standard specifications. They are by no means a limit to Continental's abilities in the engineered class applications as custom pulleys are designed and fabricated to meet customers individual requirements whenever necessary.

| BELT WIDTH | HOOD PART # | SUPPORT BAND PART # | |

|---|---|---|---|

| in. | mm | 22 GA. | 12 GA. |

| 18 | 457 | BCAG1H404571219 | BCAGGA0457 |

| 24 | 610 | BCAG1H406101219 | BCAGGA0610 |

| 30 | 762 | BCAG1H407621219 | BCAGGA0762 |

| 36 | 914 | BCAG1H409141219 | BCAGGA0914 |

| 42 | 1067 | BCAG1H410671219 | BCAGGA1067 |

| 48 | 1219 | BCAG1H412191219 | BCAGGA1219 |

| 54 | 1372 | BCAG1H413721219 | BCAGGA1372 |

| 60 | 1524 | BCAG1H415241219 | BCAGGA1524 |