Hepburn Engineering Inc.

Hepburn Engineering Inc. designs and supplies state-of-the-art mine hoists and electrical controls for the full range of operating requirements, from shaft sinking and development up to the largest production capacities, as well as complete rebuilding or upgrading services for existing hoists of all types.

Hepburn Hoist Manager is a powerful state-of-the-art window to the hoist for monitoring and control. Designed to improve hoist automation, safety, maintenance and operating efficiency, this comprehensive and user friendly system can be retrofitted to existing hoisting plants as well as incorporated into new hoists.

Continuing a tradition of innovation, Hepburn has introduced the cutting-edge Hoist Reporter as a companion to the Hoist Manager. Using the Hoist Reporter, mine management personnel can get real time hoist status and production reports at their own desks, using standard web technology.

To ensure that your Hepburn Hoist operates at peak performance, Hepburn has now introduced Hoist Care, a secure remote access solution specially designed for online mine hoist support by Hepburn Hoisting specialists.

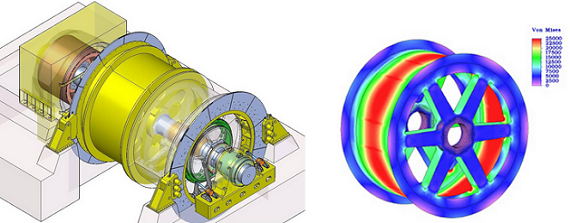

Hepburn Engineering designs, specifies and supplies the mechanical, hydraulic, electrical and control components for each hoisting system, new or rebuilt, to produce an efficient, integrated package best meeting the customers requirements. A variety of configurations, drive and braking arrangements are available and each hoist is tailored to the specific application.

HEI Mining group also supplies automated ore pocket weighing systems, head and deflector sheaves, retrofit electrical controls for existing hoisting plants, hoist inspections and field service, technical studies and a range of other hoist related equipment and services.

The efficiency of an underground mine and the safety of mine personnel are dependent upon the operation of the hoist. This demands materials, design and construction to very high standards.

Working with the latest CAD software and Finite Element Analysis techniques, Hepburn engineers use their skills and knowledge to produce efficient, reliable equipment with a solid basis in well proven designs.

This experience and expertise is also invaluable in assisting our customers in the evaluation of the best solutions for their hoisting requirements, whether it be for specifying a new hoist or the refurbishment or upgrading of an existing hoist.

HEI’s Mining group supplies hoists and controls for all types of applications including single drum, double drum, friction ( Koepe ) service or skip hoists, for single or multi-level hoisting. They are among the most technically advanced hoists available to the industry with full digital controls and automation.

Hepburn’s worldwide installed hoist population is extensive and a strong international presence is maintained by a network of effective local representatives and a corporate commitment to excellent service and reliability.

Over the years Hepburn has acquired and absorbed the engineering designs, data and detail drawings for the mine hoist technology of Canadian Ingersoll Rand, Fullerton, Hodgart & Barclay, Westinghouse Canada and Ottumwa. This places Hepburn in a unique position to provide OEM spare parts and service, overhauls or refurbishing for the many hoists previously built by these manufacturers.

- Shaft sinking platform winches

- Head and deflector sheaves

- Compensating sheaves

- Shaft mucking and material winches

- Central control systems for shaft sinking

- Hepburn Hoist Manager

- Hepburn Hoist Care

- Hepburn Digital Safety Monitor

- Remote diagnostics and support

- Hepburn Production Reporter

- Proven safety and reliability

- Regulated braking backed up by fixed level braking

- Automated braking tests

- Simple, reliable manifold design

- Semi or fully automated weighing and loading

- Fully integrated with hoist controls

- On-line production data

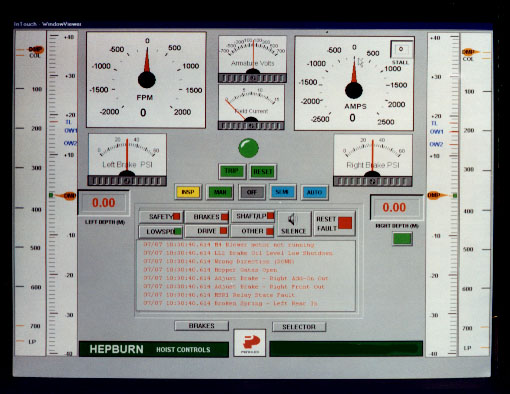

Hepburn Engineering’s "Hepburn Hoist Manager" is a powerful, state-of-the-art window into the hoist, for monitoring and control.

The Hoist Manager provides increased levels of automation for hoist operations, including automatic brake testing, over travel testing and hoist start-up. It also provides a simple way to control one or more hoists from a central or remote location. The system is extremely user-friendly for both operators and maintenance personnel.

The powerful software that underlies the graphical interface has allowed Hepburn to integrate substantial diagnostic, operating and maintenance support systems into the Hoist Manager.

The Hoist Manager fault diagnostics system provides comprehensive information for troubleshooting and component replacement and allows maintenance staff to retrieve information using graphical and picture-driven selections.

Hoist operation is carried out from the main operating screen. It provides information on the position of the conveyances, hoist speed, motor torque and excitation, brake pressures, alarms, control buttons for selecting operating states, and links to further hoisting system control and information from other screens.

The brake system screen incorporates a hydraulic schematic identifying all components in the system. Information such as brake pressure and condition of brakes and clutches is shown together with animation of valves, pumps, levels and filters. Pop-up functions provide brake static and dynamic brake testing, real time recording of valve operation, brake pressure and hoist speed.

The electrical system screen provides a schematic with pushbuttons for each starter and circuit breaker, as well as a graphical representation of fault indication and temperature monitoring of critical components.

The Hepburn Hoist Manager is tailored to each hoist where it is installed. It can be retrofitted to existing hoisting systems, as well as incorporated in new hoists, and is designed to improve hoist automation, safety, maintenance and productivity.

With Hepburn Engineering’s new remote hoist access solution, Hoist Care, remote diagnostic technical support can also be provided, using a secure link over the internet, from Hepburn Engineering’s hoisting specialists, to ensure the hoisting system's top operational effectiveness. Hepburn Engineering’s Hoist Care has been carefully designed and configured to satisfy the critical safety issues inherent in mine hoisting, allowing Hepburn Engineering specialists access to the Hoist controllers (PLC), Hoist Manager, and Hoist Reporter, without exposing the hoist controllers, Hoist Manager, or any of the core hoist control elements to the internet.

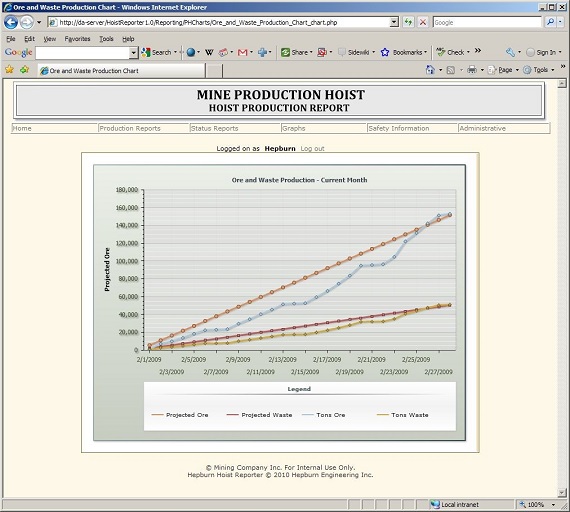

Continuing in the tradition of innovation, Hepburn Engineering also recently introduced the Hepburn Hoist Reporter, a next-generation Mine Hoist Production reporting system that complements the Hepburn Hoist Manager. Hepburn Hoist Reporter provides mine management with real-time hoist status and production reports, at their desk, or remotely, using standard web technology.

Hepburn Engineering Inc. is offering the HEPBURN Hoist Reporter, the next-generation Mine Hoist Production Reporting System. The Hoist Reporter is a software product which is integrated with the Hepburn Hoist Manager HMI, currently installed in most of Hepburn's hoists.

HEPBURN Hoist Reporter provides mine management with real-time hoist status and production reports, using standard web browsers.

Some of the benefits of the Hoist reporter include:

Some of the benefits of the Hoist reporter include:

• Monitoring hoist status in real-time, using a standard web browser from local or remote locations

• Graphical production charts

• Detailed production reports

• Recording and reporting safety system tests

• Providing a powerful web interface to the hoist alarms. Results can also be exported in a file or data format suitable to the customer.

Underway Replenishment Systems, Deck Machinery, Offshore Equipment, Integrated Control Systems, Support Services

Hepburn marine products and services have been meeting the needs of naval and commercial clients around the world for more than 30 years. Our equipment and systems have proven themselves in marine environments from the Arctic to the Persian Gulf, the South Atlantic to the North Sea.

Hepburn’s experience spans structural, mechanical, hydraulic, electrical, and control technology. Hepburn engineers use their skills to design and implement efficient, functional solutions for marine and offshore handling requirements.

Underway Replenishment at Sea

Italian supply ship "Vesuvio" refueling two ships at sea

Hepburn Engineering is the leading supplier of Underway Replenishment at Sea Systems. The Hepburn system features and performance have made it the replenishment system of choice for more sovereign navies around the world than any other system.

The Hepburn equipment functions in the STREAM (Standard Tensioned Replenishment Alongside Method), and is operated in accordance with the widely applied N.A.T.O and USN. operating procedures (i.e. ATP16 and NWP14 ).

Experience with Hepburn alongside replenishment systems suggests that the controlling factor in heavy sea states is personnel safety and the ability to maneuver the vessels, rather than any limitation of the Hepburn system to respond. Successful operation of this system has been demonstrated in conditions up to sea state 6. The equipment can be operated in poor visibility and at night utilizing pre-programmed solids transfer and automatic highline, spanwire and outboard saddle operation.

Solids Transfer from Canadian AOR

The Dual station concept was developed by Hepburn for the compact "One-stop" replenishment ship to provide solids or liquids from the same station, permitting great flexibility of transfer operations with a simplified supply ship layout and reduced equipment weight.

Hepburn has continued to lead the industry with the introduction of a choice of open deck or enclosed equipment configurations.

To assist client navies train deck crews, Hepburn can also supply on-shore trainer installations simulating RAS/FAS operations on receiving and/or sending vessels.

Hepburn Field Service personnel have recently completed sea trials on four alongside replenishment stations and one astern fueling station on the latest Spanish supply ship "Cantabria".

Underway Replenishment (UNREP) Systems:

• Liquids Stations - Fuel oil, JP5, water

• Solids Stations - Munitions, dry stores

• Dual Stations - Solids and liquids

• Open Deck or Enclosed Systems

• On-shore Trainers, RAS/FAS simulators

• Astern Refueling - Low headroom hose reels

• Receiving Stations - RAS and FAS, Sliding

• Padeyes, King Posts.

• Testing RAS / FAS Receiving Equipment

Deck Machinery & Offshore Equipment:

• Special Purpose Deck Cranes

• B.O.P. Cranes

• Special Purpose Winches

• Hose & Pipe Handling