Maestro Mine Ventilation

The revolutionary AirScout™ Flowmeter has transformed the measurement of airflow in underground mine drifts, tunnels and primary or booster fans.

The AirScout™ Flowmeter can be used in dusty, dirty and humid conditions with no effect on measurement or accuracy. In fact, the airflow is averaged between the two non-contact ultrasonic sensors ensuring the highest accuracy and repeatability in these challenging applications.

Reduce ventilation surveys with real time monitoring

The AirScout™ Flowmeter provides real time measurement without costly and outdated surveys. Real time measurements can be integrated directly into most advanced mine ventilation simulation software or OSIsoft's PI data historian through MaestroLink™ software.

Get measurement data today

The AirScout™ Flowmeter or any other Maestro AQS can be easily integrated in any analog, serial or Ethernet network. Just select your method to connect, configure the simple web pages through Windows Explorer and start collecting data. No fuss – no muss – no proprietary software!!

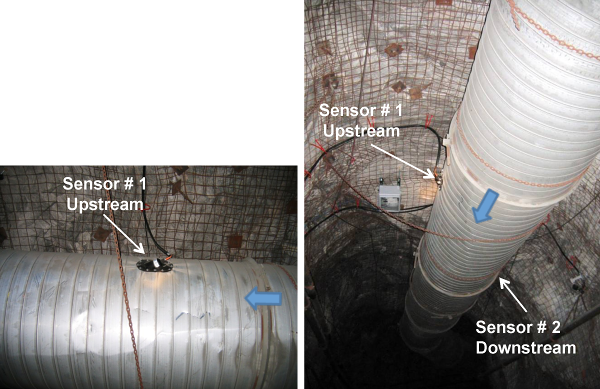

Drifts, tunnels or shafts – no problem

The digital ultrasonic sensors are a snap to install in any mine drift, tunnel or even mine shaft. The ultra-compact design allows a small form factor for easy placement in most applications. The technology is based upon using non-contact ultrasonic sensors with a range of over 85' in most difficult applications. The measurement is unaffected by dust concentration, moisture and temperature changes making it the only ideal solution in a mining environment. The airflow velocity is averaged between the two sensors leading to superior accuracy and repeatability in even the most demanding conditions.

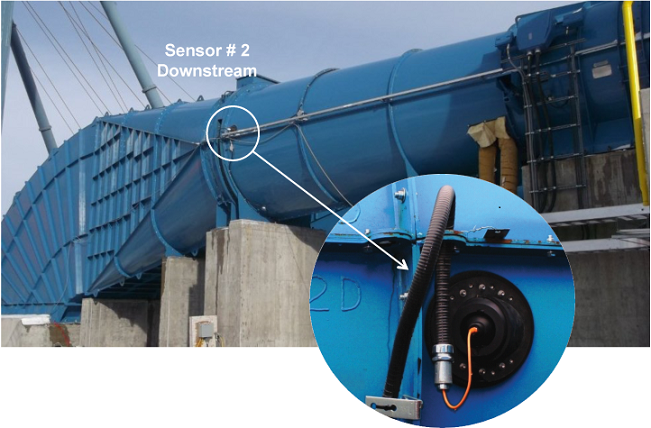

Rigid steel or plastic ducting – no welding required

Many mines utilize either rigid spiral wound round/oval ducting or plastic welded ducting sections to augment flexible fabric ducting. Maestro's Duct Mounting sensors provide the ideal connection to any rigid duct work without the need of welded fittings or special hardware. The mounting bracket is flexible and adjusts to any size of duct work from 24" (600 mm) upwards.

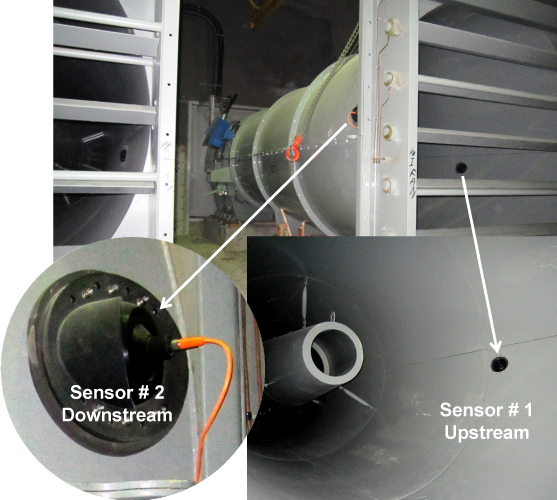

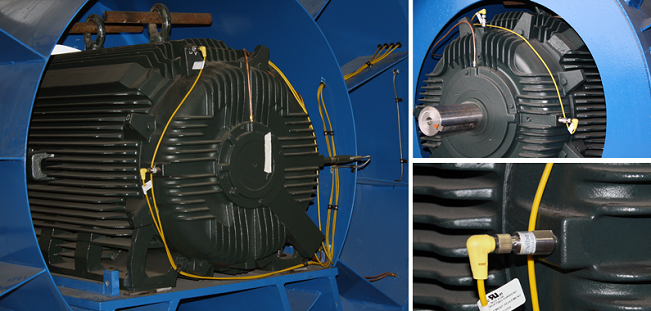

Primary and Booster Fans – the only solution!

Mine fans are the most difficult application for any airflow measurement technology - period. Ask any person that has done a pitot tube traverse.

Fan applications especially those over 700 HP (500 kW) have severe mechanical vibration, turbulent and uneven flow profiles due to high air speeds through the fan housing and directional changes in flow. This and electrical noise due the use of VFD (variable frequency drives) require the use of specially designed ultrasonic airflow sensors to provide a suitable stable but responsive measurement. The Maestro digital airflow sensor has been designed to overcome these challenges while the mounting bracket provides simple integration in all fan applications.

The Maestro FanMon™ is a complete fan monitoring system ideally used in primary and booster fan applications.

The dual LED display will dynamically display fan airflow, air temperature, pressure and vibration levels.

Each FanMon™ system is shipped preconfigured for the correct fan application.

The system provides airflow rate, static pressure, dry bulb temperature measurement. The system will accept RTD temperature inputs from the motor stator and bearings and fan damper limit switches.

The vibration system will monitor each fan bearing (inner raceway, outer raceway and rolling elements) along with total fan imbalance. The system will alarm on high vibration and allow a vibration specialist the tools to diagnose exact issue leading to the increase in vibration through visualization software. Each system comes complete with this software. The software can be remotely used anywhere on the communication network.

The system can communicate to any SCADA, HMI or PLC via Modbus TCP communication protocol.

Additionally, an analog output signal is available for vibration level and a relay is available for high vibration.

The Vigilante AQS™ is a third generation underground mine air quality monitoring station designed with an improved communication platform.

The modular design provides extremely flexible integration to any SCADA, PLC, DCS, PLS or HMI system. Whether it is Ethernet TCP/IP or RS485 serial based, the Vigilante AQS™ does it with grace and efficiency.

The single point IP address makes this system quick, simple and economical to match to any Ethernet based network.

Simply plug the Vigilante AQS™ into a network switch, configure the settings via the built-in web pages and start measuring. The register maps can easily be paired to most current or legacy monitoring platforms.

• Modular design provides ultimate user flexibility.

• Make informed ventilation decisions with real time data.

• Save time with Maestro EZ Upgrades

• Easy as PI – integration into historians

• Improve your mine ventilation simulation models

• EZ Cal gas sensors increase sensor reliability and accuracy

• Examine how the Vigilante AQS™ can provide these benefits to your mine today.

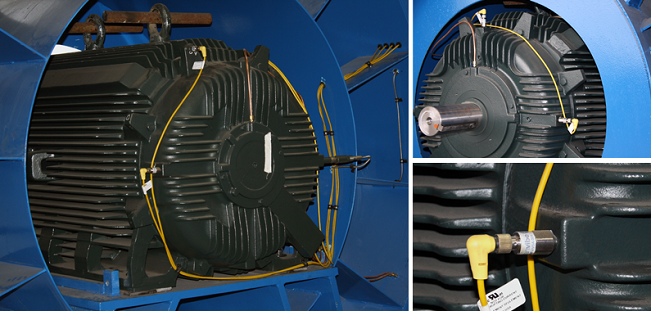

The Maestro FanVibe™ vibration monitoring system is ideally suited to measure the amount of vibration on all types of rotating equipment.

This system has been specifically designed to meet the harsh demands of fan applications which require measurement in the X-Y and Z axis.

FanVibe™ not only detects vibration data, but also carries out signal analysis and diagnostics of the fan.

The fan condition is determined and is forwarded to the PLC or to the SCADA software.

Each system comes complete with an OPC server that can be installed on the SCADA or HMI software system for easy and open interface.

The FanVibe™ system has an internal trending memory of 30,000 points which allows a detailed analysis and optimization of the application without external data recording. The storage intervals are freely selectable. This means that the storage length of the non-volatile FIFO (First in - First out) memory is optimized for each application.

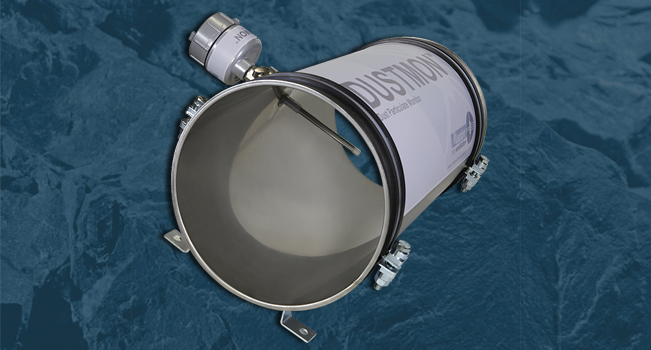

The DustMon™ is simple and effective sensor that can monitor the change in dust loading in underground haulage roads and ramps

Haulage roads can generate high dust exposures. Overexposures to respirable dust can occur to both equipment operators and workers in the vicinity of the road. The majority of the fugitive dust is generated through the forces of the wheels on the road surface and by the turbulence created by the vehicles.

Optimize dust suppressant operational costs

The DustMon™ can be added to any Vigilante AQS™ system to monitor the change in dust loading over time thereby optimizing the delivery of the dust suppressant – whether it is water, surfactants, salt solutions, petroleum resins, polymers or adhesives.

Why should dust loading be monitoring and controlled?

The National Institute for Occupational Safety and Health (NIOSH) reported occupational exposure to respirable crystalline silica dust can have several adverse health consequences, including silicosis, tuberculosis, chronic bronchitis, emphysema, and chronic renal disease and has classified crystalline silica as 2a potential occupational carcinogen.

EZ Install

The DustMon™ is simply mounted to the back of the drift along with a set of drift airflow sensors that both connect to the Vigilante AQS™ air quality station. Empirical base line testing is done to calibrate the system and alarms and output ranges can be set from the built-in webpage.

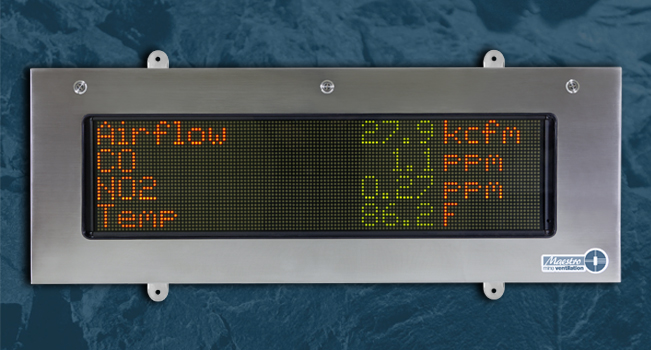

The SuperBrite™ Marquee Station Display is a fully mine-hardened, large display designed to integrate with PLC, HMI or SCADA system.

The Marquee uses state-of-the-art Tri-colour LED's arranged in four addressable lines. Each line can be addressed either as a Modbus register or by a Web Page entry. This functionality is done through the Web Page configuration interface and does not require any other software.

Through Modbus registers, the Marquee will display the tag name, tag value and tag units.

The colour along with either character solid state or flashing state can also be initiated by a register value. As an example, this function will allow a change in colour from green to amber in a high level state and a flashing red to signify a high-high level state.

Through the Web Page entry portal, a user can type in text to be displayed on the Marquee.

As an example, a Mine Captain may want to post a text message on the level where the Marquee exists. He or she will simply access the Marquee directly from any PC on the Network via the Marquee's IP address. The text can be directly added to the Web Page interface.

The Marquee also has a single analog, 4-20 mA output signal and three output relays that can be utilized over a Modbus address. These outputs could be used to turn on/off fans, control fan VFD drives, control louver positions or turn on/off external lights or annunciators.

The Marquee is fully fail-safe.

In the event of communication failure, the display will change from the last value to **** to alert to the miner that the mine communication system not working.