Symboticware Inc.

Mobile Equipment Monitoring Solution

The SymBot® is used in monitoring applications for Productivity Gains, Risk Mitigation, Energy Savings and as a platform for new development projects where real-time data collection is crucial for making better and informed decisions. The SymBot® is a ruggedized hardware/software device that acts as a hub connected to various OEM equipment to, collect, format, store and forward from remote locations, such as underground mines or remote environmental stations. The Symboticware software suite receives the data feeds, standardizes, analyzes, reports and/or integrates the data with the customer’s existing IT environment.

Real Time Visualization, Tracking and Reporting

• Operator Pre-Check

• Material Movement

• Operator and Vehicle Performance

Safer working environment, minimize equipment failure

Speed Guard is a solution that prevents mobile equipment operators from over-speeding, resulting in increased mine safety by preventing speeds in excess of equipment’s and organization’s safe operating parameters. Speed Guard saves money by minimizing premature component failure due to operating above equipment manufacturer specifications.

How does it work?

• Mounted in operator cab

• Wired into vehicle harness to engine and powertrain ECM

• Monitors vehicle ground speed and engine RPM

• Speed Guard will notify operator when pre-set value for over RPM or ground speed have been reached

• When upper threshold has been reached the operator will be notified by both a visual and audible alarm on the device

• Once alarm is triggered operator will have configurable time to lower RPM and/or speed

• If the alarm is ignored beyond configurable time the device will place the vehicle into a pre-set governed state

• Vehicle will stay in governed state until a reset can be conducted either manually or via Symbot

• Data will be logged

Safety

Prevent speeds in excess of equipment’s safe operating parameters and organization’s safe operating procedures

Component Failure

Minimize premature component failure due to operating above equipment manufacturer specifications

Production Tracking

Log run-time hour meter based on speed, RPM, and brake release for accurate production tracking

Brochure Speed Guard

Brochure Speed Guard

Brochure Speed Guard

Brochure Speed Guard

Wireless Access Point

Symboticware’s SymWAP® (Wireless Access Point) has been specifically designed to meet its customers’ demands by optimizing wireless throughput communications. The SymWAP is Symboticware’s solution for minimizing costs while maximizing deployment ease-ability in rugged environments.

With a single Wi-Fi radio housed in a rugged IP67 case, this product can be attached directly onto the walls or roof of a mine for both temporary and permanent extension of its wireless network.

The SymWAP’s leading 802.11a/b/g/n performance in both 2.4GHz and 5GHz bands, supports up to 300Mbps physical data rates, and up to 200Mbps of actual user throughput on both the uplink and downlink. 802.11n in your Wireless device provides higher efficiency for everyday activities such as local network file transfers, Internet browsing, and media streaming.

SymWAP has a high powered transmitter, bringing even greater range and connectivity to the applications you require. SymWAP is the ultimate companion to any network.

SymWap Brochure

SymWap Brochure

SymWap Brochure

SymWap Brochure

Intelligent Wireless SCADA Distributed Control System IWS HUB

The SymRTU (IWS) nodes comprise of a range of distributed wireless products from Symboticware providing advanced supervisory, control and data acquisition (SCADA) functionality for commercial and industrial applications.

With ‘out the box’ auto mesh wireless functionality, IWS nodes can be easily installed at a remote location and connected to standard sensors, supporting 4-20mA or 0-5V or using internal integrated pressure and depth measurements.

Either through a direct wireless connection or automatically hopping through a series of other IWS nodes, the sensor data is relayed back to the IWS Hub for termination over Ethernet to the IWS Management Server application for display, logging and alarm management.

The IWS Hub provides local data logging with time-stamps to ensure that no data is lost in case of communications failure on the WAN (e.g. Cell modem).

The data is securely stored on site on the IWS Hub and can be retrieved and archived using FTP. In addition, the hub continues to provide real-time data access.

Real-time data can also be accessed via a Web GUI over the Ethernet interface or over the WAN – e.g. over a cellular data connection to a smartphone or any Tablet, PC or other device that supports a standard web browser.

Features and Benefits:

• Provides Network Interface, Data Logging and Protocol Conversion for Next generation distributed, intelligent wireless SCADA system.

• Ethernet with PoE for connection to wired or wireless networks.

• Internal time-stamped data logging.

• Web based GUI for Configuration and RTU status.

• Real time web based GUI for RTU monitoring and control.

• GUI accessible via browser on Smartphone, Tablet or PC.

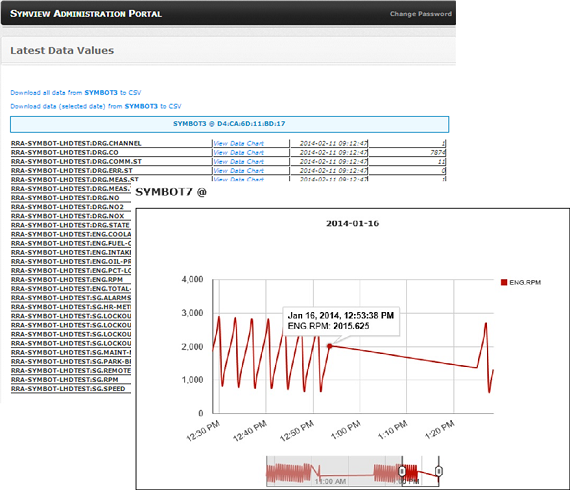

Status, Reporting, Analytics and Remote Configuration Software Solution

SymView® is a data collection software application that provides access to real-time and historical data. The application efficiently records data from process monitoring and control systems for all polled devices and sensors (ex.the SymBot, Speed Guard and SymRTU) into a compressed time stamped database capable of configuring data with trending mechanisms and predictive analysis software to predict future maintenance issues, send automated email notifications when alarms occur and create operator checklist repository and reporting mechanisms.

Features and Benefits

• Customizable Platform

• Secure Login with user ID and Password Protection

• No software installation required; web based application

• Google Maps Integration

• PI Integration

• Easy to follow screens

• Limited operator input required

• Easily deployable software

• Embedded deployments available

Technical Layout

• Software solution that collects transferred real-time and historical data, providing the capability to remotely manage, view, report and analyze raw data.

• Display’s integrated and continuous; mobile and fixed asset data, displaying real-time dashboards, reporting and event based alerts.

• Channels data to users of process control and/or data historian software, such as OSIsoft PI and GE MaxxMine, and ERP (Enterprise Resource Planning) software.

• Enables data distribution throughout the organization to multiple stakeholders.

SymBot Brochure

SymBot Brochure

SymRTU Brochure

SymRTU Brochure