Variant Mining Technologies

The Variant Arc Gate Chute is a feature-rich, cost-effective loading system designed for low-tonnage applications. Available in custom sizes to suit your environment, it is specifically designed for easy assembly and installation. This contributes to keeping your installation costs low and minimizing downtime.

Increased Durability

The chute is extremely ruggedly built, with wear points reinforced with minimum 400 BHN hardened steel liners. Liners are optionally available in 500 BHN hardened steel for maximum durability.

Improved Safety

Our Arc Gates Chutes are engineered for safety. They come equipped with a complete safety brattice system to protect workers from flying debris. Both the hydraulic and pneumatic models are failsafe.

Simplified Maintenance

The Variant Arc Gate Chute is designed for easy maintenance. All units are equipped with central lubrication systems. Improved Safety Our Arc Gates Chutes are engineered for safety. They come equipped with a complete safety brattice system to protect workers from flying debris. Both the hydraulic and pneumatic models are failsafe.

Available Options

• Failsafe hydraulic or pneumatic operation

• Custom platforms, ladders and staircases

• 500 BHN hardened steel liners for maximum durability

• PLC-based controls or relay-based controls

• Additional control inputs /outputs for handshaking with access gates, level monitoring, or other mine systems

• Pedestal, pendant, and/or infrared remote control with chute/chute interchangeable remotes

• Can be supported using structural ground supports, or self-supporting through anchoring into the drift back and walls

The Variant In-line Loading Chute is highly reliable, productive system for rapidly loading ore into haulage trucks or rail cars.

Simple Proven Design—with Improved Durability

The Standard Duty Variant Chute is a conventional headblock configuration loadout chute, incorporating several of the key design features developed with the Heavy Duty Variant Chute — lapped liner plates, perpendicular assembly joints, cast-in upper rockbox frames, and added structural stiffeners throughout the rockbox and lip structure.

Hydraulic or Pneumatic

The Variant Chute (Standard Duty) is available in either hydraulic or pneumatic configurations. Both hydraulic and pneumatic versions can be provided “fail-safe” with the ability to close and latch under loss of electrical or pneumatic/hydraulic power.

Available Options

• Sidewall access doors (blast doors)

• Wide variety of access platforms

• Lip configurations for loading rail cars or haulage trucks

• Air cannon

• PLC-based controls or relay-based controls

• Additional control inputs/outputs for handshaking with accessgates, level monitoring, or other mine systems

• Fully enclosed hydraulics systems, including integrated cooling

• Pedestal, pendant, and/or mine-safe infrared remote controlchute interchangeable remotes.

Sizes

Chutes are available in the following standard sizes:

• 3.5’ x 6’

• 4’ x 6’

• 4’ x 8’

• 5’ x 8’

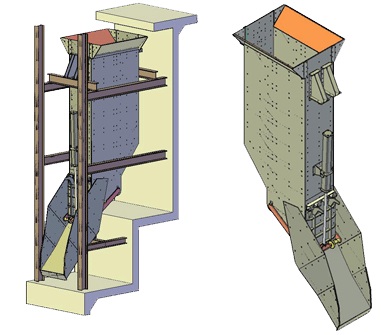

The Variant In-Line Loading Chute (Super Heavy Duty) is step forward in the evolution of In-Line Loading Systems. It is specifically designed for high tonnage ore passes where a chute is expected to last many years.

Increased Durability

The chute is a extremely ruggedly built, with heavy reinforcement on all sidewalls, lip walls, lip floor and pin connections. The lip pins are brass bushed and pinned, providing a zero-radius hinge— with no hinge crush point.

The rockbox is designed to be cast directly into concrete—not simply anchored. This provides additional rock-box reinforcement in the area that it’s most needed. All liners are lapped over bolted joints, and bolted joints are all perpendicular to the muck flow.

Improved Safety

The Super Heavy Duty Chute is designed from the ground-up with a failsafe hydraulic system. It includes side-mounted gate and lip cylinders, providing much safer maintenance access than traditional chute designs.

Simplified Maintenance

The sidewall-mounted cylinder configuration eliminates the entire headblock assembly—a high maintenance area in traditional chute designs. The traditional sidewall extension plates are replaced by heavy sidewall extension liners which fit inside the main lip sidewalls. The provides better maintenance access, and eliminates a narrow bolted connection.

Available Options

• Sidewall access doors (blast doors)

• Wide variety of access platforms

• Lip configurations for loading rail cars or haulage trucks

• Air cannon

• PLC-based controls or relay-based controls

• Additional control inputs/outputs for handshaking withaccess gates, level monitoring, or other mine systems

• Fully enclosed hydraulics systems, including integratedcooling systems

• Pedestal, pendant, and/or infrared remote control withchute/chute interchangeable remotes.

Sizes

Chutes are available in the following sizes:

• 4′ x 6′

• 4′ x 8′

• 6′ x 8′

• 5′ x 8′

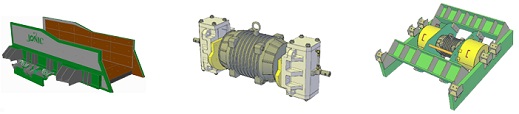

Variant Mining Technologies’ innovative Vibratory Feeders are designed to transport and redirect muck in underground circuits. Built to the highest engineering standards, they can be incorporated into your existing systems or coupled with Variant Mining Technologies’ industry-leading chutes.Each Vibratory Feeder is custom-built to meet our customers’ individual requirements. Our Feeders are completely cageable and specifically designed for easy installation. They can be pneumatically or hydraulically driven, according to your needs.

Maximum Durability

Variant Mining Technologies Vibratory Feeders are designed to withstand the most extreme conditions. With wearpoints reinforced with 400BHN or 500BHN hardened steel liners, our Vibratory Feeders are built to last.

Variant Mining Technologies Vibratory Feeders feature a Dynamic Rotary Cylinder, a pneumatically controlled adjustable counterweight. Milled from a solid block of T6061 high-strength aluminum and lined with 1/4” nitro tubing, the Dynamic Rotary Cylinder is extremely durable and light. With a maximum feed rate at 0 psi, the Dynamic Rotary Cylinder is not only reliable—it is also energy efficient.

Standard Features

• Bolts on each cylinder cap allow internal access from either end of the cylinder.

• Easy-to-access external grease fitting on rotary coupling.

• Dry O-ring sealed cylinder caps for clean assembly and disassembly.

• Lift points integrated directly into the Dynamic Rotary Cylinder.

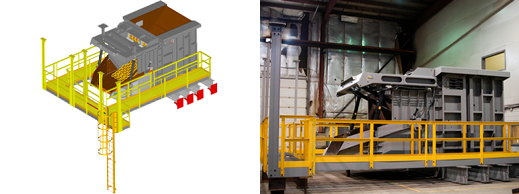

Custom-built to suit your application, Variant Measuring Boxes can be used to load skips, haulage trucks, ore cars, and conveyors. They are pre-assembled and tested in the Variant manufacturing facility prior to shipment.

Models

Models

We offer both volumetric and gravimetric models of measuring boxes:

Volumetric Measuring Boxes

Our volumetric measuring boxes are precisely dimensioned using material with accurate density and size to maintain an accurate payload measurement.

Gravimetric Measuring Boxes

Our gravimetric measuring boxes are supported on heavy duty load cells that provide a continuous accurate read-out. Size or density of material is no longer a critical factor.

Standard Features

• Meets ANSI/ASCE wind load and seismic requirements.

• Checkless design does not require load cell stays or check rods.

• Double cantilever design improves system performance and accuracy.

Available Features

• Wear liners available to best suit your application (such as 500HS, rubber and Domite).

• Pneumatic or hydraulic operation, including complete control systems.

• Infrared wireless control.

• Integrated arc gate chute.