BCIT Engineering Project Sponsored by Sepro Mineral Systems Corp. Intiates Development of New Small-Scale Gravity Concentrator for Field Use

By Dev Saini

Sep 25, 2015

|

|

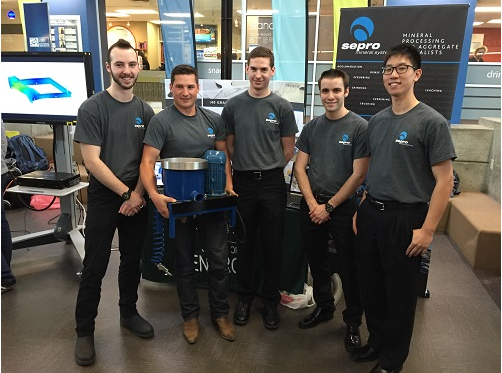

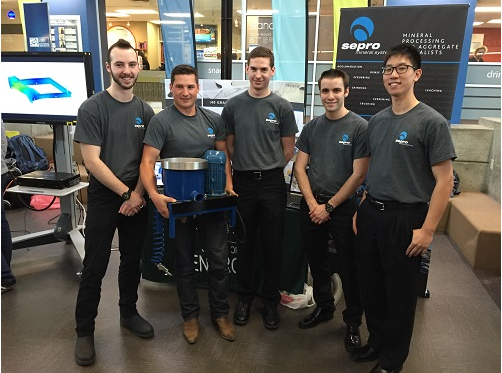

BCIT MECH 4490 Project Team from left to right: Kevin Bryan, Myles Panz, Carlton Matzek,Braedon Bainbridge, Zachary Oyama |

Earlier this year at the annual British Columbia Institute of Technology (BCIT) Mech Expo, a group of BCIT students showcased their concept design for a small-scale, cost effective, gravity concentrator that could be sold to artisanal miners for field use. The project was completed as part of MECH 4490 Engineering Design/Projects, which is a required class for the completion of the Mechanical Engineering Technology Diploma at BCIT.

The basis of the project, The Falcon Gravity Concentrator, is typically utilized for the recovery of fine minerals and materials in a wide range of industries. Sepro Mineral Systems Corp. offers three models of Falcon Gravity Concentrators: Ultra Fine, Semi-Batch and Continuous. Each Gravity Concentrator has a specialized purpose dependent on the application and stage of recovery required within a given mining operation, plant or circuit.

Sepro was pleased to sponsor the project as it was an opportunity to support local British Columbian engineering students while also exploring the long-term feasibility of developing a small scale gravity concentrator for hard rock mining applications. The idea was initiated by team member, Braedon Bainbridge who at the time worked as a Project Draftsman at Sepro while concurrently completing his Mechanical Engineering Diploma at BCIT. Braedon has since been promoted to full time Project Engineer at Sepro.

Braedon’s BCIT project team met with Sepro management to discuss new product development concepts which hadn’t been fully realized. This discussion lead to the final decision to focus on the new concentrator prototype as the basis of the assignment. Sepro maintains a progressive role in the education of post-secondary students given the significant part they will play in establishing future engineering solutions and endeavors.

Ultimately, the main focus of the small-scale Falcon prototype produced by the team was to create a cost effective concentrator that could be utilized by artisanal miners in countries such as Peru. The prototype was made out of mild steel, and incorporated a single phase AC motor. The simple design greatly contributed to meeting the desired cost objectives.

Following the success of the project and graduating from the Mechanical Engineering Technology Diploma in summer 2015, team member Kevin Bryan was hired by Sepro to develop the original prototype into a final working model. With an improved design, the new model will feature a further reduction in weight and cost.

Details on the new small-scale gravity concentrator project will be provided in future updates.

Source: http://www.seprosystems.com/sepro-mineral-systems-news/bcit-engineering-project-sponsored-by-sepro-mineral-systems-corp-intiates-development-of-new-small-scale-gravity-concentrator-for-field-use#.VpjoIfmLSCo