Pepper Maintenance Canada

Vibration Analysis

Vibration analysis is a natural diagnostic tool for equipment. Vibration--the destructive movement present in all rotating machinery--needs to be understood for infrared analysis to be done in the most effective manner. There are many causes of vibration.

Why is Vibration Analysis so Important?

There are occasions of multiple causes of failure, which also require a complete analysis of all issues. Pepper Maintenance technicians are thoroughly trained in vibration analysis.

In addition to gathering vibration data, our technicians can interpret that data and diagnose problems. Randy Springer is experienced in both vibration analysis and infrared and has completed two vibration courses with IRD Mechanalysis and Robert Schleiser of St. Louis, MO.

Pepper Maintenance maintains a close association with Springer Engineering of Fort Wayne, IN for expert engineering assistance when needed.

Causes of Vibration

Electrical

Aerodynamic or Hydraulic Forces

Reciprocating Forces/Pistons/Engines

Resonance

By the way....is air a liquid, solid, or gas?

Examples

Causes of Vibration

What Makes This Thing Shake?

Unbalance is the most common cause, but that is not always the case. Unbalance is caused by a heavy spot, from various sources and conditions; rarely is it the primary reason for vibration.

• Misalignment-couplings/bearings and bent shafts; why do motor bearings fail? which one fails first?

• Bad bearings

• Eccentric journals--think of it as being off-center

• Bad gears or shafts, bent or chipped teeth, normal wear and more

• Mechanical looseness

• Bad drive belts; when replacing one gear on chain drive, always replace both (same for sheave)

• The mark on the belt; with unit properly locked out, place a chalk mark across multiple V belts, and rotate the unit by hand; observe what happens to the marks as the belts rotate at different rpm's

Electrical

• Rotor not round

• Eccentric armature journals

• Rotor and stator misalignment - unequal air gap

• Elliptical stator bore - egg-shaped barrel

• Open or shorted windings

Aerodynamic or Hydraulic Forces

• Blade pass - in water or air

• Why fan housings vibrate opposite the rotating blades

Reciprocating Forces/Pistons/Engines

Back and forth, stop and go the other way

Resonance

• Everything runs smoothly until the second dryer is started

• A machine's "natural" beat

• A great way to bring down the Golden Gate Bridge

By the way....is air a liquid, solid, or gas?

Examples

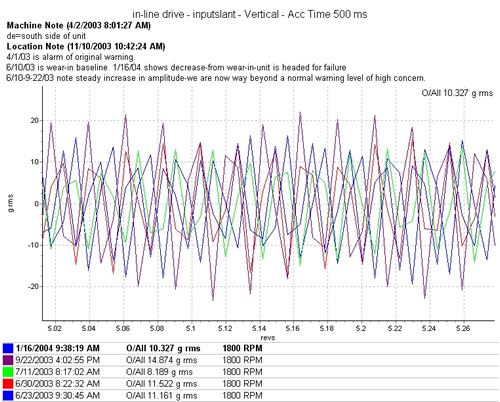

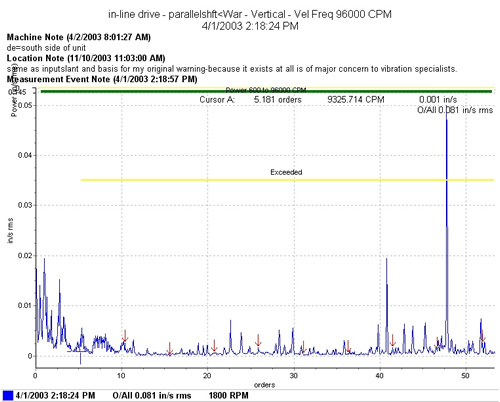

Failure in Progress

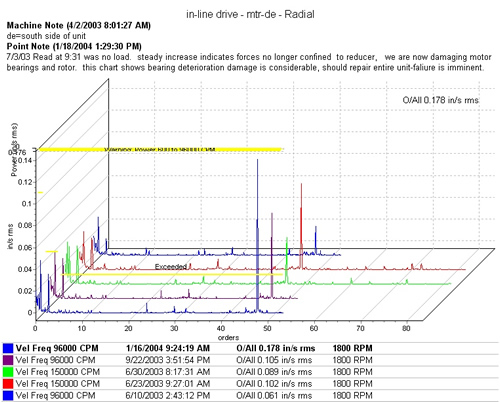

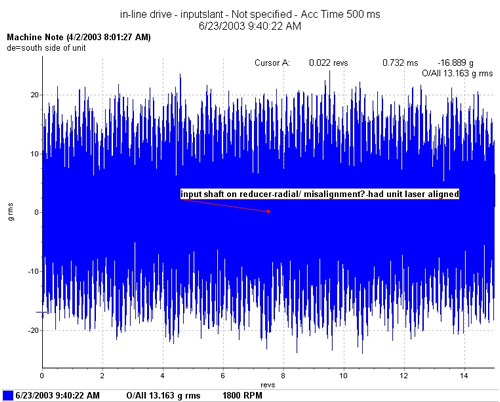

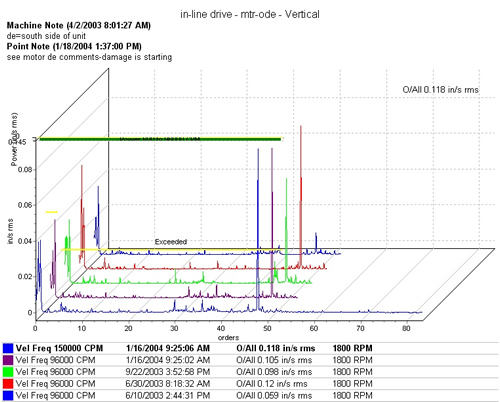

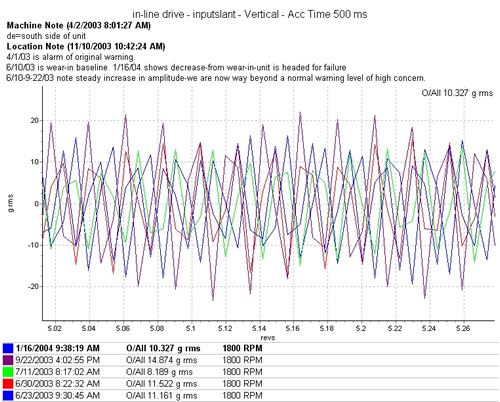

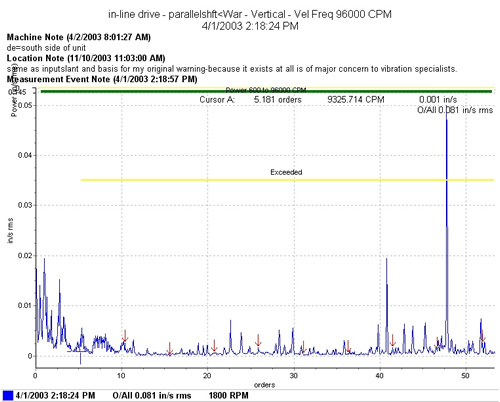

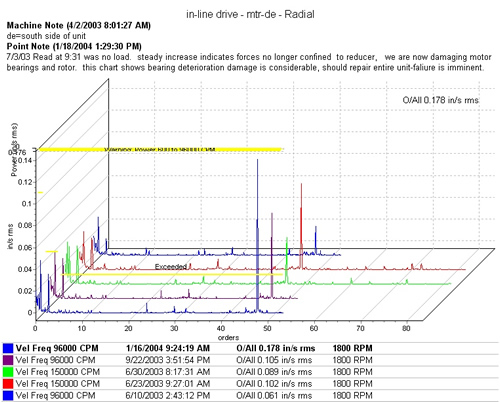

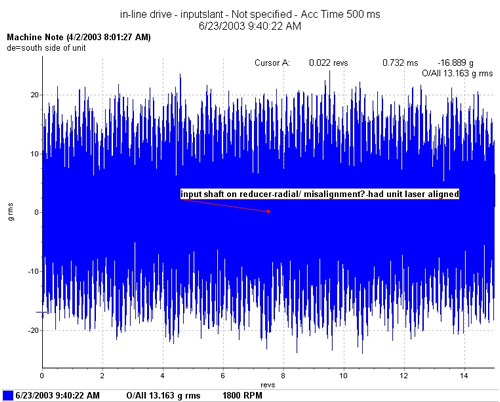

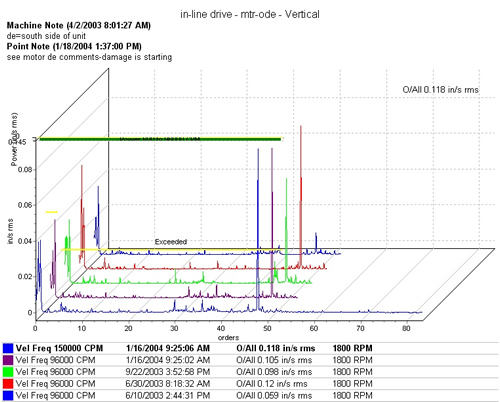

Since June, 2003, Pepper Maintenance has been observing and monitoring the imminent failure of an extremely large, high horsepower gear reducer. The customer is fully aware of the deteriorating condition of the equipment. Pepper Maintenance will continue to monitor the situation until the customer is able to remove the equipment from service for maintenance and repair.

The signatures of failure are graphically obvious in the real-life illustrations exhibited here. Follow the detective-technician's trail as he listens to the heartbeat of this huge reducer over multiple, consecutive visits. These signatures are from the actual report provided to the customer, showing the progressive deterioration.

High Speed Output Shaft

Motor Inboard Bearing

Imput Shaft

Mototr Outboard Bearing

Input Shaft

Above Input Shaft

High Speed Output Shaft

Motor Inboard Bearing

Imput Shaft

Mototr Outboard Bearing

Input Shaft

Above Input Shaft

Source: https://www.peppermaintenance.com/vibrational-analysis