Pepper Maintenance Canada

Infrared Analysis

Infrared Overview

Pepper Maintenance Systems thermographers are predictive maintenance specialists. They serve the industrial processing and grain industries. Pepper believes that experience is important as is staying current with changing technology. Studying heat and vibration, they are able to identify potential weaknesses in equipment--weaknesses that could lead to major damage and cost thousands of dollars in repair.

What is Infrared Thermography?

Also called "thermal imaging," infrared thermography is the study and analysis of heat. Infrared thermography uses the law of thermodynamics, and although electrical applications are the most widely recognized, uses extend far beyond the electrical to:

When to Schedule an Infrared Survey

• Bearings

• Motors

• Motors

• Drives

• Belts

Pepper Maintenance Stresses the Importance of.....

1. Knowledge: how hot should this be?

2. Communication with key plant operations personnel

3. Predicting the future and learning to trust the thermographer

When to Schedule an Infrared Survey

The sooner potential problem areas are identified, the better chance you have to avoid costly down time. Although any time is a good time to do a survey---equipment does not have to be at full load---crucial productivity periods may not be the best time. Maintenance operations are already short-staffed in many locations. We will work with you to find the optimal time.

Savings are clear and may be substantial. Ask yourself:

• What is the value of a day lost, and what is it worth to your future?

• What is a smoothly operating plant worth?

The Thermographic Survey

Infrared thermography survey technology is a recognized and proven form of nondestructive testing. A diagnostic tool used in preventive maintenance, infrared thermography has a wide range of applications.

Thermographic technology helps detect potential breakdowns before they occur. Predictive maintenance complements any industry's approach toward the most efficient and economically feasible, total maintenance plan.

Survey Results and Reports

Thermographic Examples

The Thermographic Survey

Infrared thermography survey technology is a recognized and proven form of nondestructive testing. A diagnostic tool used in preventive maintenance, infrared thermography has a wide range of applications.

Thermographic technology helps detect potential breakdowns before they occur. Predictive maintenance complements any industry's approach toward the most efficient and economically feasible, total maintenance plan.

Survey Process

Pepper Maintenance Systems, Inc. uses the technology found in the FLIR system for the Thermographic Survey services they offer. All testing is done during plant operation while equipment is under load.

The images recorded during these surveys are used to diagnose problems in:

The images recorded during these surveys are used to diagnose problems in:

• Electrical panels

• Overhead lines

• Electric motors

• Many other applications that generate abnormal amounts of heat

Survey Results and Reports

During the survey, a Pepper Maintenance thermographer records abnormal heat variations in a unit both digitally and orally.

Our themographer also develops a detailed, written report. The report contains color images that show the source of heat, all pertinent information and suggestions for correction. Your Pepper Maintenance thermographer is trained to provide the most accurate and reliable reports. Pepper Maintenance provides the written report to the surveyed facility as soon as possible, but first reports critical conditions to management for their immediate and direct attention.

Standards for Analysis

Standards for Analysis

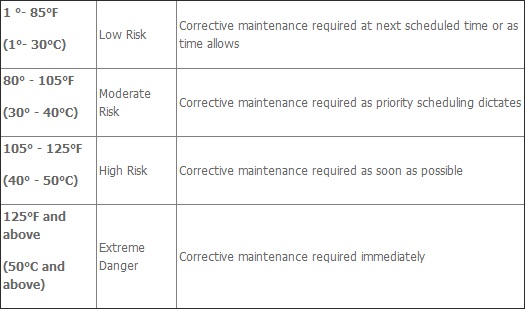

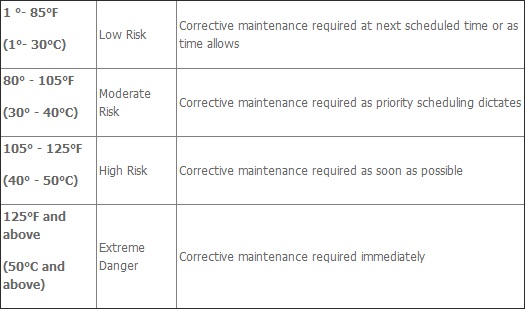

Standards for Analysis and Corrective Measures

Thermography survey field experience shows that component temperature levels above ambient levels indicate need for repair and maintenance response. Decisions for corrective action should be based on the measured degree of differences within individual components and the effect of an equipment or plant shut down. Actual percentage loads upon individual equipment comprising the thermographic survey are not determined. Each unit surveyed is in an "as is" condition.

Voltage Systems 120V - 480V

Temperature Differential of "Hot Spot" Measured Versus Ambient

Thermographic Examples

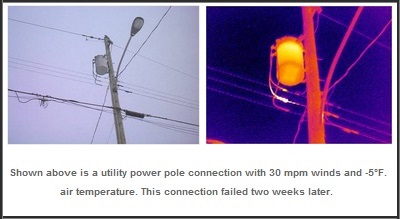

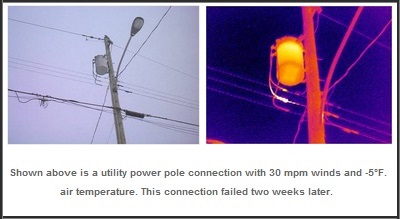

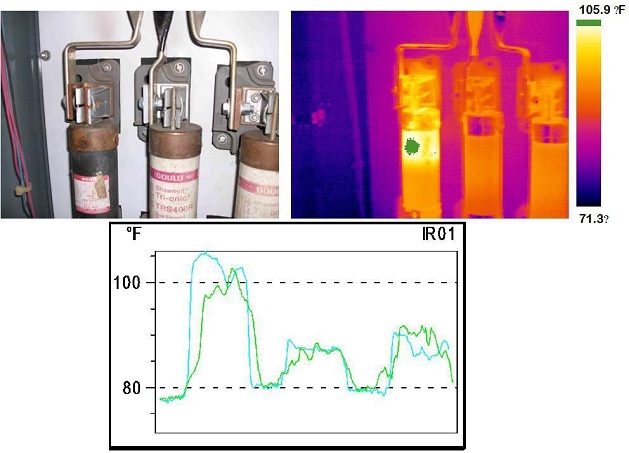

View examples of actual hazards identified during a routine Pepper Maintenance survey below:

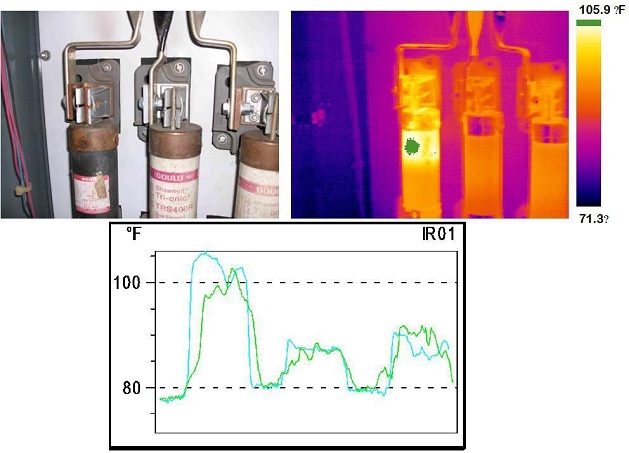

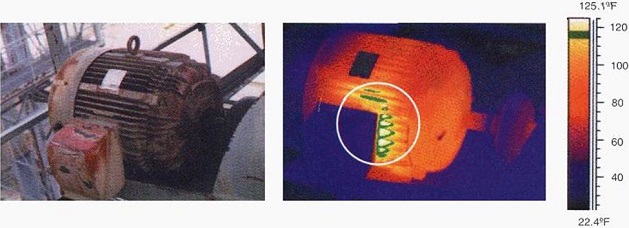

How to read the sample data: The hot spot in each example is circled with a line through the location of the highest temperature. The color of the hot spot corresponds to a color on the temperature scale.

Note: Ambient temperature is indicated at the bottom of the temperature scale. Abnormal temperature rise above the ambient temperature is what indicates the hot spot and a probable trouble spot.

|

Motor Coupling |

Motor Phase Imbalance |

|

|

|

Masthead Connections |

Starter/Thermal Unit |

|

|

|

Conveyor Belt |

Fuse Disconnect |

|

|

|

Tail Pulley Bearing |

Fuse Disconnect |

|

|

|

Fuse Disconnect |

Fuse Disconnect |

|

|

|

Fuse Disconnect Reflective Heat |

Conveyor Tail Pulley Bearing |

|

|

|

New Dryer Breaker |

Primary Feed Connection |

|

|

|

Gear Reducer Input Shaft |

Transformer Connection |

|

|

|

Head Pulley Bearing |

Normal Transformer Connection |

|

|

|

Motor Bearing |

|

|

Source: https://www.peppermaintenance.com/infrared-analysis