Pneuma-Tool Inc.

Improved Workplace Safety

How oil mists affect phisical performance

How oil mists affect phisical performance

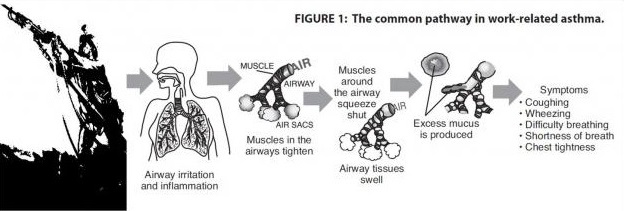

Our lungs are poorly equipped to handle irritants such as dust, smoke and oil. When these contaminants enter the lungs, the body secretes mucous to prevent the contaminant from being absorbed into the bloodstream. These secretions diminish the lungs’ capacity to absorb oxygen, and reduce the bodies ability to perform.

The effect is similar to operating an internal combustion engine with a dirty air filter. Performance is sluggish, and more energy is consumed to perform tasks.

You can’t expect optimum performance from your miners if the air they are breathing is contaminated.

Reduced environmental impact

Pneuma-Tool™ is inherently biodegradable, making it the right choice for ecologically sensitive areas, and one less pollutant of concern for the mine operator.

Flexibility

Pneuma-Tool™ is available in several grades to allow the mine operator to optimize product consumption, fogging, tool performance and cold weather attributes. New cold weather formulas remain fluid and functional in temperature extremes as cold as -50C

WHMIS / OSHA compliance

Pneuma-Tool™ meets more stringent air quality recommendations for airborne particulate contaminants, such as those developed by the ACGIH, for the metalworking industry.

Reduced consumption

Pneuma-Tool’s patented polar formulas operate at the “LOW” setting on the lubricator, which means less inventory to buy, ship, store, and handle. Needle and seat lubricators enable operators to reduce consumption by as much as 80%.

Outstanding wear performance

Pneuma-Tools’s new wear additives provides a 0.20 -0.30 mm wear scar (depending on viscosity) on the Four Ball Wear test, measured at extreme parameters of temperature (up to 70 C.) and pressure (up to 40 Kg.)versus 0.20 - 0.60 mm for the leading competitors, measured at much lower parameters (average 20 C / 20 Kg.). Tool performance and tool life are both enhanced, especially under conditions of high torque and load, such as in bolting. These tests more accurately represent the severe conditions encountered in mining.

Pneuma-Tool is suitable for use in all types of pneumatic equipment, such as, but not limited to:

• Jack Legs and Stopers

• Bolters

• ITH Drills

• Alimak Raises

• Long Hole Drills

• Vertical shaft Muckers (VSM's)

• Face jumbos

• Face bolters

• Diamond Drills

• Air Cylinders

• Tugger Motors

• Bit Grinders

Source: http://www.pneuma-tool.com/news.html

Magazine

No information