Pneuma-Tool Inc.

Improved Tool Life

Pneuma-Tool Improves Tool Life in 4 ways:

#1 - Superior Oxidative Stability

Pneuma-Tool resisted oxidative breakdown 3X longer than the competition in lab tests. When oils break down they produce abrasive carbon particles that quickly produce tool wear. Bolting produces the ideal conditions to break down oils. Pneuma-Tool has been proven to maintain its lubricating qualities at temperatures estimated to be between 465 and 485F. At these high temperatures, most competitive oils break down and lose their ability to protect the tool. Pneuma-Tool's flash point is, on average, 100F higher than its most other rock drill oils, which means that Pneuma-Tool protects the tool at temperatures that are well beyond the capabilities of its major competitors.

#2 - Superior Anti-Wear and Extreme Pressure Additives

Pneuma-Tool produced wear scars on the four ball wear test that were 50% less than the competition, under severe load conditions such as are encountered in bolting operations.

#3 - The polar attraction of Pneuma-Tool to metals provides consistent reliable lubrication.

Pneuma-Tool adheres tenaciously to metal surfaces and provides consistent tool protection even under severe conditions and with reduced or interrupted flow. The tool runs cooler, and due to the high oxidative stability of Pneuma-Tool, the lubricant remains effective at a greatly reduced replenishment rate as compared to traditional rock drill oils.

#4 - High Viscosity Index

Pneuma-Tool's high viscosity index means that it thins out less at high temperatures, providing good metal to metal separation and thus longer tool life.

Pneuma-Tool also becomes less viscous at cold temperatures, reducing tool lag and minimizing freeze up at the muffler.

Stoper Torture Test

A new stoper was bench tested with Pneuma-Tool at 185 CFM, 110 psi, 125 F ambient air - NO STEEL - NO WATER

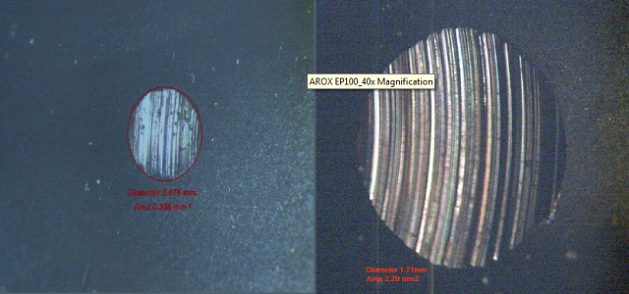

The tool was run for 8.5 hours, and reached operating temperatures internally that were estimated by the tool manufacturer to have reached 465 to 485 F. The stoper was disassembled and inspected by the manufacturer at the conclusion of the test. All parts were within manufactured specifications, and the tool was reassembled and sent into service. There was no sign of tool damage. The photos below show the breakdown of traditional rock drill oil at high temperature (left), and the phase separation of an overbased calcium sulfonate liquid grease at approximately 300 F. Once the liquid grease has separated, the calcium sulfonate (the centre glob), can dry out and form solid deposits within the tool, which can block lubricant flow. This will eventually lead to premature tool failure.

Source: http://www.pneuma-tool.com/about.html

Magazine

No information