Winding and Reeling

Roll quality is critical to ensure problem free operation in the pressroom. If the wound-in-tension is not correct the roll can have crepe wrinkles or bursts which will cause breaks in the pressroom. These problems can be resolved with measuring the tension, nip load, and torque differential (TNT) of the winding process along with the density profile. Since reeling on a paper machine is another winding process, problems here are resolved in a similar manner. In this case, special attention must be paid to the primary arm lowering and the transfer of the reel to the secondary arms.

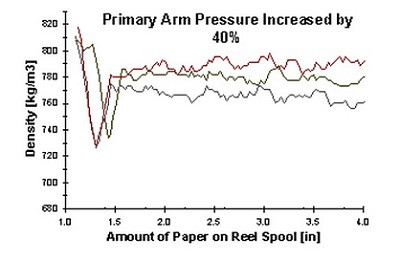

Figure 1 Density profile with primary arm loading increased by 40%.

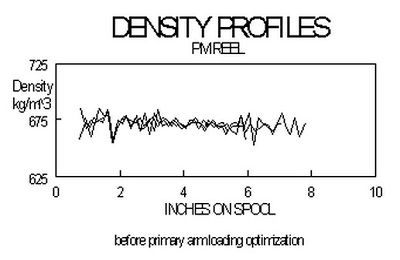

Figure 2 The density profiles after the bumpless transfer was installed. Note the repetitive downward density spike at 1.75" jacket.

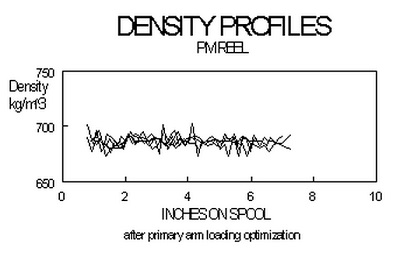

Figure 3 The density profile after the bumpless transfer was optimized.

Spectrum Technologies works closely with LSZ PaperTech to supply consulting services in winding and reeling.

Source: http://www.spectrum-tec.com/english/pulpandpaper/windingreeling.html