Spectrum Technologies Ltd

Wet End Survey

Determine the Source of Basis Weight Variations

Have you ever looked up through your paper at a source of light and seen large scale light and dark spots, particularly as the paper was traveling through the winder at low speed? Or has a paper analysis determined that there is excessive variability in your paper? In either of these cases, a wet end survey is recommended.

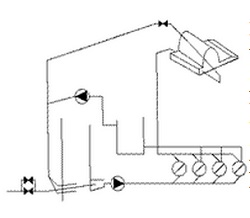

Basis weight in the sheet is determined by the mass of pulp fibers being frozen into the sheet. The uniformity of the basis weight depends upon the stability of the flow coming from the headbox, the stability of the headbox itself, the consistency uniformity of the stock, and the type of former.

In a wet end survey, measurements of the wet end are taken to determine the cause of the variability in your paper. Typically, pressure measurements are taken on the taper header and upstream to the fan pump. These pressures determine the level of pulsation at the headbox. Vibration measurements are taken on the headbox. The vibration survey is extended to other components as necessary. The rotational speeds of the main wet end components are measured. These can be critical to determining the source of the problem. Depending upon the type of variation present, the consistency may need to be measured as well.

These measurements are compared to the basis weight variations. If there is a relationship between the process measurement and the basis weight, then we are one step closer to determining the source of the problem. The measurements are continued until the source of the problem is found.

If the variation is occurring at frequencies around 1 Hz, then a wet end audit is recommended. All this work needs an intimate knowledge of the process along with the dynamic characteristics of the equipment.

Source: http://www.spectrum-tec.com/english/pulpandpaper/wetendsurvey.html

Magazine

No information