Bruel and Kjaer EMS Inc.

Hardware Maintenance

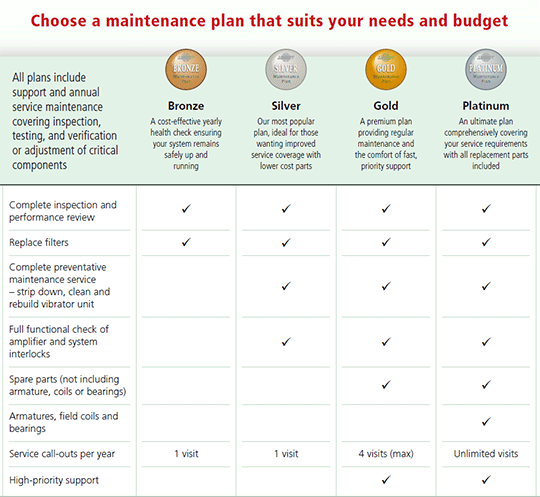

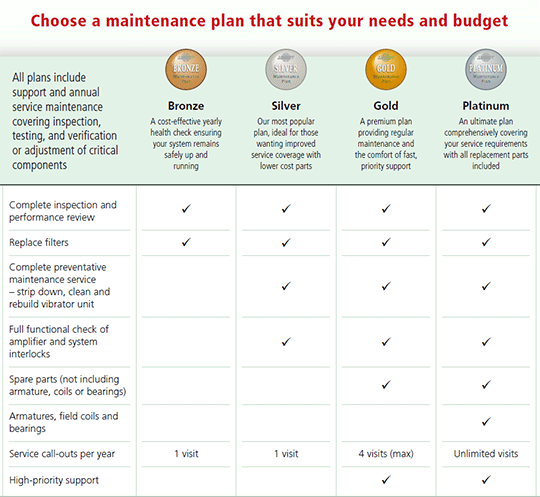

Hardware maintenance and field service for LDS vibration test systems - Type S0100 (Bronze), S0101 (Silver), S0102 (Gold), S0103 (Platinum)

Regular preventative maintenance is essential to keep your vibration test system delivering top performance, safety and reliability for decades to come. We offer a range of service and maintenance plans to choose from, so you can enjoy the peace of mind that comes from knowing your investment will always be operating at optimal capacity.

Our services are designed to minimise downtime, maximise the life of your equipment, and avoid unplanned repair costs. They are performed by specialised service professionals who are highly trained in vibration test system (VTS) maintenance and repair at Brüel & Kjær's factory.

Service agreement and preventative maintenance plans

All mechanical systems with moving parts require preventative maintenance from time to time. The most effective way to manage the associated costs and services is through a planned maintenance schedule and service agreement.

• Maximum uptime

Maximise your productivity by detecting issues before they become larger problems, to avoid unplanned downtime

• Improved test quality

Keeping your vibration test system well maintained will improve your ability to manage its performance and consequently improve the consistency and quality of all your tests, data and results

• Increased lifetime

Consistent professional servicing and maintenance will increase the lifetime of your vibration test system, extend the intervals between servicing, and improve the return on your investment. A well maintained, professionally operated vibration test system can provide decades of reliable operation.

• Manage operational costs

Planned maintenance and servicing gives a known annual spend while minimising the risk of unexpected operational service costs

• Genuine LDS spare and replacement parts

All service and replacement parts installed under the service agreement and preventative maintenance plans are genuine LDS parts from Brüel & Kjær. These are manufactured to precise tolerances and meet the original manufacturer and material specifications. Replacement with non-original parts can have a negative effect on system performance, can lead to the breakdown of more complex and costly components, and will invalidate your warranty.

• Factory-trained service personnel

All maintenance and service is performed to Brüel & Kjær specifications by our highly skilled teams of service engineers and technicians. Our service teams provide the highest level of competence in the industry thanks to extensive training and many years of hands-on experience of Brüel & Kjær equipment.

• Additional operator training available

We offer professional product training to keep your staff updated on the latest vibration test procedures, developments and trends. Our training courses help ensure your equipment is used within the recommended specifications by providing guidance on the proper test and measurement procedures and safe operating practises.

Source: http://www.bksv.com/ServiceCalibration/Services/HardwareMaintenance

|

Application Engineer

Application Engineer, part of the Americas Support Group and is responsible for supporting both our customers and Sales Engineers in the sale and use of our products.

Software Engineer

Prenscia Engineering Solutions is looking for a talented Software Engineer to join our fast growing team in Southfield, MI.

Accounts Receivable Accountant

You will be responsible for collections of outstanding accounts receivable from the existing client base and the end to end process of collections, managing and establishing credit limits, and reducing accounts receivable delinquency.