Paradox Access Solutions

Market Outlook - Lumber & Access Matting

Up until now access mats were the most efficient and affordable way to ensure your crew and equipment could safely travel to and from your work site. Due to their highly versatile nature, the access matting industry has had increased prominence in many temporary access solutions. The most common access mats are wooden due to their affordability and ease of acquisition; this leads to concerns related to the variability of the lumber market. However, other access mats composed of rubber, composites, fiberglass and bamboo remain available.

Throughout the years the lumber industry has fluctuated. However, recently the lumber industry has seen a sharp increase in demand and a worrying inventory shortage causing prices to surge. The effects of the contrasting forces in the lumber market can be felt across the economy. The price for a single 2x4 used to be $3.50 and is now $9.80; the price for OSB plywood was $12 and is now $56 per sheet. You might want to consider postponing your deck renovation. This has also had a drastic impact on the access matting world.

Lumber Market - What is Causing the Change?

In Canada, the provincial governments mandate an Annual Allowable Cut (AAC), which ultimately defines the amount of timber that can be harvested within a defined planning area. The AAC is often altered to maintain sustainability; thus, the AAC varies from year to year.

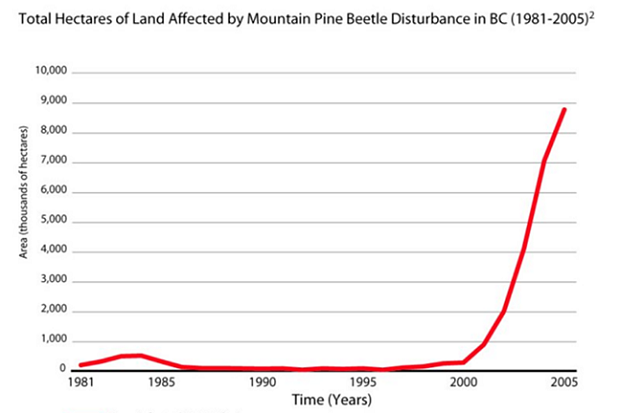

Several years ago, the pine beetle ravaged many forests in Northern British Columbia and Alberta. In order to effectively eradicate the pine beetle all infested trees had to be cut. The provincial governments of British Columbia and Alberta subsequently increased the AAC to help combat the pine beetle and allow harvesters to cut more trees.

Following the pine beetle incident, British Columbia experienced two summers of major forest fires in the Central and Northern regions, leaving many trees burnt and in need of harvest. Following the fires, the AAC was once again increased to eliminate potential waste from not cutting down burnt trees. By not cutting down the trees following the fire the lumber would eventually lose its usefulness.

The growing cycle for trees in Canada can range from 60-100 years, therefore, the AAC must be lowered to account for the prior provincial increases. This decrease helps enforce the sustainability of the lumber industry and helps prevent shortages in the future. However, as a nation we are beginning to feel the effects of the lowered AAC as producers harvest amounts have been decreased.

Another consideration within the lumber industry is the additional cost of stumpage fees. The stumpage fees are paid for by logging companies to the owners of the land (usually the government). For wood such as pine or spruce the 2020 August stumpage fees were $36.56 - $67.31 per cubic meter in September.

Lumber Market - Pandemic Influence

On top of the decreased AAC another global phenomenon has impacted the lumber market. Early in 2020 the COVID-19 pandemic forced many manufactures to cease or slow production to a minimum, in keeping with the mandated lockdown orders. The pandemic further depleted the already low supply of treated and ready-to-sell lumber.

Finally, to support the slowing economy, North American governments lowered interest rates to encourage spending once again. The lowered interest rates have sparked a housing boom with similar magnitudes to the boom preceding the 2007 financial crisis. Home buyers began surfacing to secure a mortgage with an attractive interest rate, and housing prices soared. Accordingly, new home construction skyrocketed as it became viable to build a home; however, with a dwindling lumber supply, prices were driven to an all-time high.

The price for lumber in June of 2020 was fluctuating between $350-$400 per thousand board feet; in May of 2021 the price has reached a record setting high of $1670.50 per thousand board feet, and recently dipped closer to the $1300 mark.

How are these Changes Reflected in the Access Matting Market?

The access mat market is relatively small compared to the entire lumber industry, nonetheless, it remains a crucial component for many construction projects. Access matting is often the foundation for many project startups; without access matting, heavy machinery and resources required for construction projects would not be able to reach the intended jobsite. This is especially true for construction projects in areas where environmental sensitivity is crucial. They also perform well in locations where muskeg and unfavourable ground conditions are present.

The access mat market does not stand alone, rather it is highly correlated with the lumber market. The price of an access mat is dependent on the price of the lumber from which it is made, and currently that lumber is reaching a price point higher than ever recorded.

Access matting manufactures in North America are reporting a 30-40% increase in sale pricing over the last six months to help account for the increased cost of lumber. Furthermore, some manufacturers have slowed or ceased mat production as costs continue to steadily rise and demand shrinks. Instead of purchasing mats outright, project managers have shifted towards renting access mats to help cut costs.

While renting access mats appears to be a reasonable solution to the higher purchase costs it has its own drawbacks. All mats come with an expiry date and mat rental companies are being forced to raise their rental prices as the inevitable purchase of new expensive inventory approaches.

Alternative Solutions

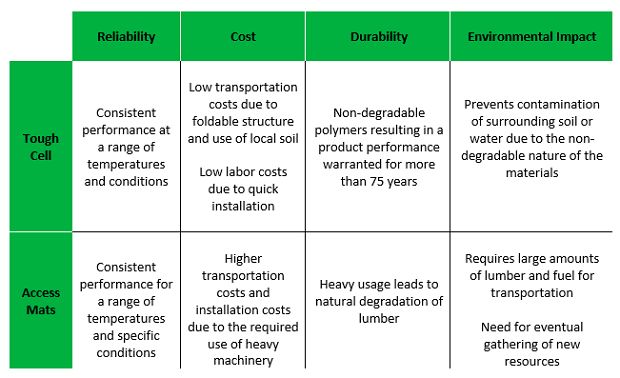

It has become necessary for many project managers to seek out alternative solutions to unstable ground conditions. One solution has proven to standout among the rest: Tough Cell Technology - honeycomb like structures that can be utilized in the aforementioned conditions prevalent in Canada.

Benefits of NPA Tough Cell

Cost Reduction

Tough Cell provides the opportunity to: use local infills, reduce transportation costs, create long term durability with low maintenance needs, facilitate fast installation with local work crews, and adapt to changing weather conditions; all of which contribute to a lower expense placed on the customer.

Green Solution

Tough Cell requires less hauling and heavy machinery use when being installed which means there is a significant reduction in carbon emissions and the environmental footprint. Furthermore, it requires less ground removal and deforestation than other solutions.

Sustainability

The combination of geotechnical structures and the Neoloy (NPA) material present in Tough Cell solutions enables a structural integrity improvement of up to 75 years.

Summary

As the economy continues to catch up to the low supply and high demand of lumber, it remains imperative that projects stick to their timelines. Access matting still maintains its benefits, however, as the cost continues to climb, new solutions should be considered. Tough Cell has proven to be a reliable and cost-effective solution to the shifting economic conditions in the post pandemic world.

Source: https://blog.paradoxaccess.com/market-outlook-lumber-access-matting

Class 1 Driver

Paradox Access Solutions is seeking a Class 1 Driver to join their team!

Senior Marketing Coordinator - Contract

Paradox Access Solutions is seeking a Senior Marketing Coordinator to join their team!