Paradox Access Solutions

You Deserve More Durable Roads—Tough Cell Technology Is Here to Make That Happen

Roads, like all engineered structures, must stand up to the punishment of the elements and traffic. According to the 2019 Canadian Infrastructure Report Card (CIRC), “there are enough Canadian roads in poor condition to build a road almost halfway to the moon.”

But just because this is the way things are, doesn’t mean it’s the way things must continue to be. Today, we’re going to explore how advancements in roadbuilding and geotechnical engineering technologies are enabling companies and governments around the world to build roads in ways that offer:

- Significant reductions in carbon emissions from construction activities;

- Long-term cost savings thanks to reduced material required and maintenance, and;

- Longer-lasting, more durable roads.

Which elements of road construction mean the most to you?

If you’re an engineer, owner, project manager, or contractor involved in the construction and maintenance of a road, bridge, sidewalk, or other similar infrastructure, it’s critical that the long-term integrity and cost are considered as you decide which technologies to leverage when building the road—regardless of whether the asset in question is public or private. If the up-front cost is cheap but the projected maintenance schedule and costs are too high to commit to wholeheartedly, is it really worth it?

Until recent years, this was basically the only option. Build a road today and maintain it frequently for years to come. If your road is publicly owned, you will suffer the incessant calls of displeased drivers and rattled taxpayers. But this is changing—and it’s changing fast.

Paradox Access Solutions introduced Tough Cell technology to the Canadian market in 2009 with the mission to deliver state-of-the-art roadbuilding solutions that are eco-friendlier, more affordable, and easier to maintain than any conventional options. Consider this:

Construction Materials

- A conventional road building company typically requires 25,000 tons of crushed stone per 2 kilometres. With Tough Cell, your project can realize 25% savings on aggregate infill volume versus conventional builds—we’ve seen savings of as much as 50% in some cases.

- You can reduce pavement thickness by up to 50%.

- Tough Cell performs well by improving the modulus of lower grade infill. This allows you to use locally available inferior aggregate sources, which wouldn't normally be used in conventional builds. Inferior aggregates include recycled asphalt and concrete (RAP, RAC, sand), saving money and reducing your carbon footprint.

Construction Time

- Full depth sub grade preparation is usually not necessary for Tough Cell, eliminating a substantial portion of preparation. Soil replacement is minimized, and many times eliminated. Ultimately, such shallow treatment takes a fraction of the time.

- More time and money are saved because the base and sub base layers require fewer “lifts” (passes of material and compacting equipment). And since you can easily use locally available materials, you can save time and costs on trucking infill from excessive distances.

- The asphalt concrete pavement (ACP) thickness for a Tough Cell road is generally 25% less than that of a conventional base and this translates to less time and money spent on constructing this expensive layer.

- Finally, Tough Cell can be installed under almost any weather condition including northern climate winters.

All these result in shorter traffic disruptions, lower overhead and less time on site in general.

Paved Roads

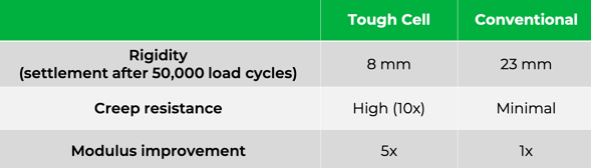

Asphalt and concrete surfaces often require less than half the thickness of base course layers when Tough Cell is employed even while bearing capacity is increased by a factor of 2-3x. Studies show that Tough Cell provides a high modulus improvement factor (MIF) of 3-15x, depending on infill material and subgrade condition.

- For the paving itself, the asphalt concrete pavement (ACP) can be reduced by up to 25% of the normal thickness without compromising the support structure.

- If you will be using reclaimed asphalt pavement (RAP) as a filler, there's no need to ship back to the plant, to mix with virgin aggregate and chemical reagents. Plus, you don't have to haul new aggregates to fill the geocells.

- The geocell confinement reduces creep and improves the modulus of RAP infill in a wide range of milled grade sizes, including poorly graded materials.

- By reducing vertical stress and reducing differential settlement, increased traffic and loadings can be accommodated with less rutting, less pavement failure, and less maintenance.

Unpaved Roads

Unpaved roads were designed many years ago, for much lighter traffic (horse and buggies and model Ts). Today we have much larger equipment (even in the agriculture industry).

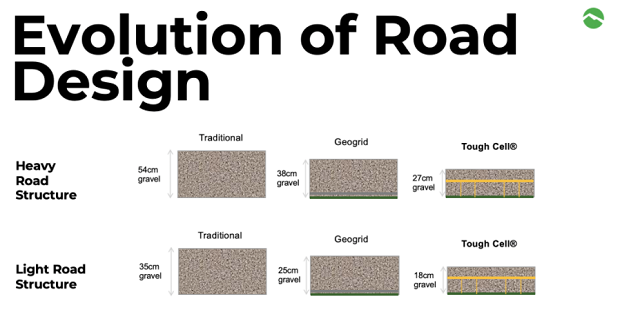

For roads to be able to handle today's increasing population, heavier traffic and axle loads, a durable, long-lasting solution is required. Tough Cell roads offer a longer service life with less maintenance and less costs. Tough Cell reinforcement results in thinner overall road structures than traditional methods, yet possess greater stiffness. And, because Tough Cell significantly increases base course strength, you can reduce layer thickness by at least 25%.

In addition, weaker soils can be reinforced and used for subgrade support without compromising integrity, and gravel attrition is greatly reduced (up to 5x improvement) to meet current requirements. All this adds up.

Construction Costs

The combined savings on construction materials and time add up to significant savings, depending upon the different conditions.

- Labour, material, and equipment costs can be significantly lower compared to conventional methods for both construction and total cost of ownership.

- Gravel costs can be reduced significantly by up to 40% because of reduced volumes.

- The Tough Cell advantages should result in overall initial construction cost savings over conventional methods and often much more.

Maintenance

Tough Cell reduces maintenance cycles and life-cycle costs. This results from the reinforcement properties of Tough Cell geocells maintaining the grade structure with minimal material attrition. This means that when you build with Tough Cell, asphalt life can generally be expected to increase by up 50%, so you can expect a lifespan of up to six years by using Tough Cell compared to four years using comparable materials. Furthermore, you’ll enjoy a significant increase in base and subbase lifetimes.

The most heavily used infrastructure made with Tough Cell experience dramatic reductions in maintenance costs over the course of time. One example of such an installation is currently saving our client over $1,000,000 per year in maintenance costs compared to their previous conventionally constructed yard.

Environment

With the road construction industry showing no signs of slowing down and requiring a huge amount of finite resources, the importance of reducing its footprint is paramount. According to Natural Resources Canada, the Canadian construction industry’s greenhouse gas (GHG) emissions have increased by approx. 75% from 1990 to 2017 (4.4Mt of CO2 and 7.7Mt CO2, respectively).

Tough Cell technology slashes consumption and emissions in road construction.

- First of all, far less infill and paving materials are needed for construction when using Tough Cell. Low material attrition and extended maintenance means less material consumption over the life of the surface.

- Secondly, building with Tough Cell demands less equipment usage, thereby reducing CO2 emissions by 20% or more thanks to reduced hauling, processing, placement, and compaction requirements.

- And, because lower quality infill can be used with Tough Cell—including recycled or waste materials—while still delivering stronger, longer-lasting roads compared to conventional methods, you can use local supplies that may be unsuitable for other purposes (and benefit from reduced logistics to transport it).

- Finally, RAP material can be used as-is, without additives or expensive processing.

Durability

Tough Cell geocells are made from a novel polymeric alloy (NPA), which uses nanotechnology to deliver a stronger, more durable material for geocell fabrication. Controlled tests project that Tough Cells can provide road structure support without failing for 75 years, far longer than any other geosynthetic product.

Other tests show that Tough Cell can provide unprecedented strength as great at 22 kN/m and can function in climates ranging from subarctic freeze to Saharan desert (-60°C to +60°C) without degradation or deformation.

Is Tough Cell the right solution for your next project?

When it comes to road design and construction, it’s important to remember that each project has its own set of unique factors that require thorough consideration in order to establish the optimal project design and construction methodology.

For some projects, traditional methods may serve best—for others, leveraging more advanced technologies (such as geosynthetic textiles and NPA geocells) may substantially enhance a project’s KPIs.

The good news is, you don’t have to figure any of that out alone. Our geotechnical engineering and Tough Cell experts are here to help you determine the best path forward based on your project’s unique characteristics. Talk to us today to get started!

Tough Cell versus the others?

HDPE

Research by the University of Kansas and the Indian Institute of Technology, Madras, comparing Tough Cell to HDPE-based geocells and webbing has proven that Tough Cell’s construction provides superior benefits. Tough Cell provides:

- a higher elastic modulus

- greater improvement in terms of stiffness

- greater load bearing capacity

- superior stress distribution

- reduced deformation

HDPE geocells are typically used for soil erosion control in slope and channel protection applications, and as low earth retention structures, but their use in base reinforcement and load support applications is often limited to low volume roads and temporary pavement structures, because they can often lack the necessary stiffness and durability.

Tough Cell geocells have a higher tensile stiffness and strength, and are more durable over time and under elevated temperatures than HDPE geocells. This makes Tough Cell a more cost-effective solutions for long-term, low maintenance solutions. Plus, NPA geocells carry a 75 year manufacturers warranty.

HDPE (left) stretched and deformed under pressure while Tough Cell (right) stayed its original shape and size.

DMA

Polymers tend to lose elastic modulus over time, particularly under dynamic loading. A geocell system must maintain stiffness and elastic properties without permanent deformation or loss of geometry, which could result in losing confinement or even worse crack and fail.

The Dynamical Mechanical Analysis (DMA) examines the net elastic modulus of polymers. The analysis extracts the polymer stiffness in the elastic mode – the ability to apply loads on the system without permanent deformation.

A stable net elastic modulus also ensures elastic behaviour at elevated temperatures.

This method is well supported by ASTM and ISO standards and commonly used in the automotive, electronic, military industries. The following table summarize the Tough Cell geocells Elastic (Stiffness) Modulus Properties.

Geogrid

Tough Cell creates a reinforced mattress with a beam effect when applied to unbounded base material. Compared to 2D geosynthetic products, such as geogrids and geotextiles, geocell confinement in three dimensions reduces the lateral movement of soil particles. This results in a higher locked-in confining stress and thus a higher modulus of the base.

Conventional ground stabilization solutions (soil replacement, soil cements, or thicker base layers) either do not provide sufficient long-term stability and strength for transportation engineering, and/or entail higher costs and environmental impacts.

Source: https://blog.paradoxaccess.com/build-more-durable-roads-with-tough-cell-technology

Class 1 Driver

Paradox Access Solutions is seeking a Class 1 Driver to join their team!

Senior Marketing Coordinator - Contract

Paradox Access Solutions is seeking a Senior Marketing Coordinator to join their team!