SKF Canada Ltd.

Test and Measuring Equipment

|

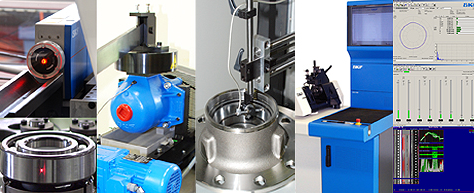

| As a major engineering company, SKF needs to make sure that it provides products and services that meet its own high standards. Measurement and quality-assurance systems, based at our own Condition Monitoring Centre for test and measuring equipment (CMC-Steyr), have provided the means to do that for the last 25 years. |

| Today, we offer the same capabilities to customers. SKF develops and supplies the latest technology and instrumentation, designed to gauge compliance with each customer’s defined goals. A full range of measurement approaches fulfill the quality assurance needs of manufacturers of high precision round parts and related products, as well as grease testing for the grease industry. |

| SKF also works closely with other specialists, if required. Installation, setup, training (on or off site) and extensive follow-up activities are all part of the services supplied. In addition, SKF offers a range of gauges to check tapered shaft journals or the radial internal clearance of cylindrical roller bearings. They are designed to meet the requirements of high-precision technology, especially in machine tool and spindle manufacturing and spindle repair services. |

| Technology and measurement approaches include: |

|

• Waviness, roundness and form analysis • Noise and vibration testing for bearings • Dimension testing • Optical inspection • Non destructive testing • Grease testing machines |

| A noisy application might be caused by wavy bearing components, local defects in the rings and balls or by dirt particles in the bearing. While basic requirements on a bearing like stiffness, load capacity, speed limit and service life play a critical role in applications, low noise and vibration are becoming even more important. |

| All of these bearing quality issues can be tested with bearing vibration equipment by SKF. |

| High tech analysis and measurement such as frequency analysis (FFT) and further advanced analysis pinpoints faults. Spectral masks help to optimize the bearing performance in the particular customer application. |

| With some experience, the measurement results of these machines can also be used by experts to detect imperfect manufacturing steps, such as missing honing for example. The introduction of a worldwide calibration system permits vibration equipment to be set to operate according to international standards. |

|

SKF provides products and solutions for a wide variety of optical measurement and optical inspection applications related to bearing manufacture. Primarily for rotation symmetric components, such as balls, rollers, rings and bearings, industrial optical inspection equipment from SKF keeps costs to a minimum while maximizing your application. In optical systems, the following basic physical principle is involved: "The appearance of the product is different to what we have decided to be acceptable." That appearance is dependent on three factors: |

|

• condition of the object - colour, roughness, etc. • nature of the illumination - white light, coloured light, laser light, etc. • properties of the sensors - matrix camera, line camera, single photo-detector, etc. |

| SKF specializes in all three of these areas, as well as in signal processing and handling of the products. Our goal is to keep factories running efficiently by helping to establish zero defect production and to control the surface appearance of your products. |