American Mine Door

Door Automation

Door Automation

The American Mine Door Co. has the ability to design controls to operate your mine door package. After initial review of your specific needs, we will offer the customer a written description of exactly how the control system we design will operate. At that time, the customer will review the system operation overview and make any final alterations that they want included. American Mine Door Co. will build the controls in-house, complete a thorough testing of the system, and then complete wiring schematics and installation instructions for the customer.

Automation control highlights:

Automation control highlights:

• Increase safety and productivity while maintaining air lock integrity by using an American Mine Door Co. PLC automation package.

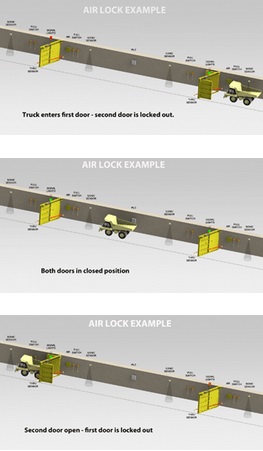

• 1 door, 2 door “air lock” and 3 door “T” automation control packages available. Each automation package is unique and has been proven in hundreds of installations in many types of mines.

• Our control packages have evolved over the last 10 years by listening to our customers’ needs.

• We only use the highest quality enclosures and components to assemble packages to survive many years of trouble free service.

• We will custom design and program automation packages to solve any unique customer issue.

Our controls packages offer the ability to automate your air locks. Secure your air lock by locking out one door, use thru-door scanners to detect obstacles between the doors to avoid injury or damage. Open/close doors via sonic sensors to detect vehicles approaching and exiting your doors - eliminating idle time”

Control Features:

• NEMA 12/13 enclosure

• Allen Bradley Micrologix 1000 PLC

• Line conditioner in each system

• All Allen Bradley components (relays, terminal blocks, switches, fuse holders etc.)

Available options and programmable logic control packages:

• Door interlock logic – lock out 1 door in airlock to maintain neutral airways.

• Logic for “T’s” and “cross” traffic patterns.

• Lighting systems (green, red and yellow shows traffic conditions).

• Buzzer/ horns for audible alerts.

• Rope pull switches – used to manually open/close a mine door.

• Thru-door scanners – scan between the door wings during the close cycle to detect anything between the doors. If any object is identified during the close cycle the doors wings will immediately open to avoid injury or damage.

• Sonic sensors – located on the roof of the mine, a sonic sensor is placed a predetermined distance at the entry and exit of the mine door. When the sonic sensor identifies a moving object, a signal is sent to the PLC which signals the door to open or close. These can be used in track or trackless mines very effectively, significantly reducing idle time at each mine door.

• Remote control systems via remote transmitters.

• Cap lamp sensors to activate door systems.

• Above ground controls of your mine doors via Ethernet communication cable.

• Bump style safety curtains affixed at the door wing edge (at center where door wings come together). Used as an E-stop in the event an object comes into contact with the curtain.