Home >

Suppliers Companies

> Hydraulique NES >

Products > DYNASET > HPWDUST High Pressure Dust Suppression

Hydraulique NES

HPWDUST High Pressure Dust Suppression

DYNASET HPW-DUST Dust Suppression System converts the hydraulic power of a mobile machine into a high pressure water mist. It is integrated onto the base machine’s attachment head or where the dust suppression is needed to get the maximum effect. The system creates an effective high pressure dust control with optimal water consumption. High pressure water uses less water and gives better dust suppression performances with a smaller water drop size than traditional low pressure dust suppression systems.

BASE MACHINES AND INSTALLATION

The compact HPW-DUST is easy to install onto any mobile machine. It is suitable for demolition machinery, excavators, screeners and crushers. The nozzles of the HPW-DUST are installed either straight to the attachment head or anywhere dust suppression is needed.

HOW DOES THE DYNASET HPW-DUST HIGH PRESSURE DUST SUPPRESSION SYSTEM WORK?

The HPW-DUST Dust Suppression System uses the power from the base machine’s hydraulic system. The HPW-DUST patented piston-to-piston pump converts the hydraulic power into high pressure water. It is pumped to the carefully designed dust suppression nozzles which create the atomized water mist.

PRODUCTIVITY

Integrating the HPW-DUST system on to a mobile machine increases the machines versatility and utilization rate. Compact system takes minimal space and is easy to use. It has a powerful dust suppression effect that binds the dust with a minimal amount of water. A smaller drop size bind more dust particles and improves the dust suppression compared to low-pressure dust suppression systems. The machine operator can simultaneously use the HPW-DUST and machines tool. The operator also has better field of view with the targeted dust control. This minimizes the need for multiple equipment and operators. It saves costs and time, enabling larger utilization of machines with less work force.

A smaller drop size bind more dust particles and improves the dust suppression compared to higher water volume dust suppression systems.

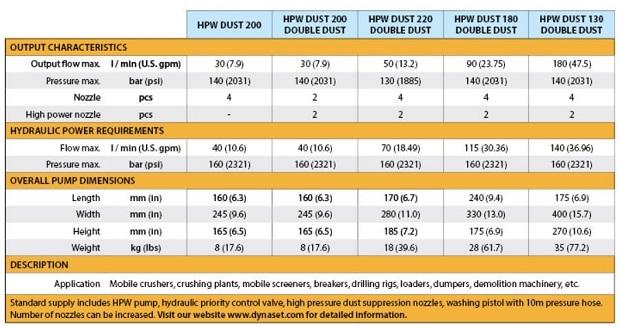

MODEL & SPECIFICATIONS