|

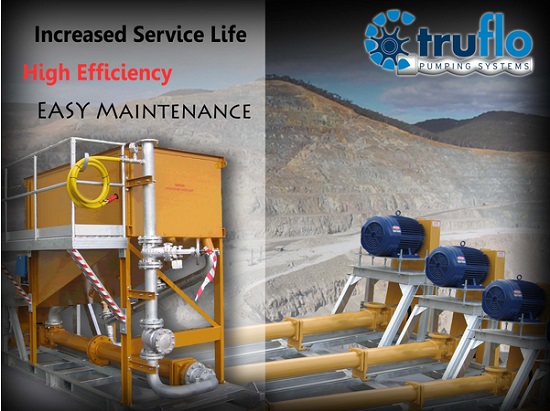

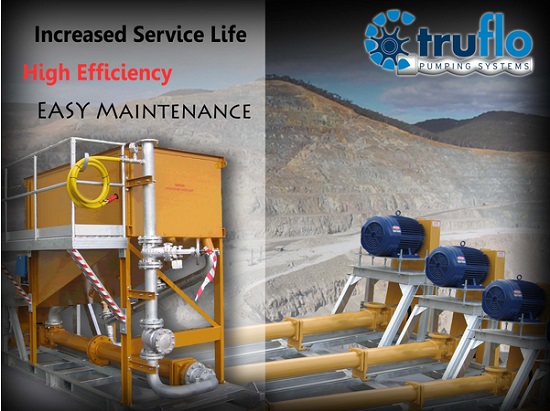

TRU-FLO continues its commitment to provide quality products, system solutions and after-sale support and service to national mining companies. |

|

|

|

The TRU-FLO product has been designed to offer exacting footprint specifications, parts interchangability, flange/pipe-work compatibility and improved performance on helical rotor pumps previously installed into mine dewatering applications. |

|

|

|

|

|

|

Body Components: Discharge port/end cover fabricated from stainless steel to improve corrosion and erosion resistance and longer life at the stator seal point. Suction chamber extension is fitted with a stainless steel insert at the stator seal for extended seal life in corrosive applications. All external hardware is manufactured from stainless steel. The unique split ring design improves serviceability by removing the cumbersome tie bar arrangement previously used. Flexible Shaft Joint: Having no wearing parts and without the need for lubrication, the rotor adaptor offers high reliability and lower maintenance. This simplistic joint provides optimal serviceability. |

|

|

|

Flexible Drive Shaft: The flexible drive shaft is manufactured from toughened materials and is now covered with an improved thickness of chemically inert, abrasive resistant Halar coating. |

|

|

|

Heavy Duty Bearing Housing: The TRU-FLO range employs labyrinth-bearing seals at the DE and the NDE of the bearing housing to provide maximum bearing protection in the moist, corrosive and dusty environments experienced in underground mining. The pumps are fitted with tapered roller bearings, which have been selected for long life and continuous operation in the most arduous of applications. A triple greasing point system is used for the bearing housing body for bearing lubrication and at the DE and NDE labyrinths. The bearing cover is sealed with Loctite 5370 to prevent contamination of bearing lubricant through end cover joint. Bearing lubrication is a lithium based high temperature, high performance (EP) grease. |

|

|

|

Rotor: All rotors are manufactures from 316+410 stainless steel for maximum corrosion and abrasion resistance. |

|

|

|

Stator: TRU-FLO Natural rubber double bonded resilient synthetic stators offer maximum abrasion resistance. |

|

|

|

Rotor Coating: The TRU-FLO range has increased the HCP coating from 0.25mm to 0.4mm and improved the chrome quality by using the MAHC chrome technology. This provides benefits such as extra hardness and improved frictional properties for extended life when pumping highly corrosive and abrasive liquids. |

|

|

|

Shaft/Flexible Shaft Joint: Having no wearing parts and without the need for lubrication, this joint offers high reliability and simplified maintenance. The tapered joint allows removal of the bearing housing assembly without the need for dismantling the pump or disconnecting the pipe-work. |

|

|

|

TRU-FLO Shaft Sleeve Sealing as Standard: The TRU-FLO range offers soft packed gland running on the unique tough, wear resistant coated shaft sleeve as standard. The shaft sealing on a helical rotor positive displacement pump is performed on the suction side, which makes this system ideally suited for high head abrasive liquid transfer. Split stainless steel gland follower (3 piece) for simplified gland packing access and maintenance. |

|

|

|

|

|

TF 082 Pump Data Sheet

TF 082 Pump Data Sheet TF 084 Pump Data Sheet

TF 084 Pump Data Sheet TF 088 Pump Data Sheet

TF 088 Pump Data Sheet TF 102 Pump Data Sheet

TF 102 Pump Data Sheet TF 103 Pump Data Sheet

TF 103 Pump Data Sheet TF 104 Pump Data Sheet

TF 104 Pump Data Sheet TF 106 Pump Data Sheet

TF 106 Pump Data Sheet TF 4 Pump Data Sheet

TF 4 Pump Data Sheet