Calhoun Super Structure

Hot Dip Galvanization

The Hot-Dipped Galvanizing Process

The Hot Dipped galvanizing process means that Calhoun Super Structures last longer. Studies show that next to stainless steel, hot dipped galvanizing (HDG) is the best protection against rust and weathering. Hot dip galvanizing process makes our trusses strong and more reliable while creating a smooth surface that won't snag or tear the cover.

Here's how it works.

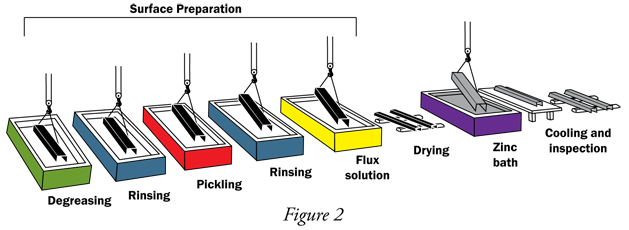

Surface preparation

Galvanizing involves bonding zinc to steel, and surface preparation is extremely important. If it is not done correctly, the zinc won't adhere to the steel and sections will be left uncoated. Our steel undergoes three stages of preparation.

Caustic Cleaning

A hot alkali solution removes organic contaminants, such as dirt, paint markings, grease and oil from the metal surface. Epoxies, vinyl, asphalt, or welding slag must be removed before galvanizing by grit blasting, sand blasting or other mechanical means.

Acid Pickling

Scale and rust are removed from the steel surface by pickling in a dilute solution of hot sulphuric acid or ambient temperature hydrochloric acid.

Fluxing

Fluxing removes oxides and prevents further oxides from forming on the surface of the metal prior to galvanizing. The steel is dipped into an aqueous solution of zinc ammonium chloride. The material is then dried prior to immersion in molten zinc.

Galvanizing

Each welded truss is completely immersed in a bath consisting of a minimum of 98% pure molten zinc at a temperature of about 840°F (449°C). The zinc metal then reacts with the iron on the steel surface to form a zinc/iron inter-metallic alloy. The trusses are then withdrawn slowly from the galvanizing bath, and the excess zinc is removed by draining and vibrating. Because the galvanization process involves total immersion, all surfaces are coated- providing protection for both the outside and the inside of the steel tubing used in the trusses.

Inspection

After the trusses have dried, the galvanizer closely scrutinizes the coating thickness and appearance. Through a battery of physical and laboratory tests, they determine thickness uniformity, adherence and appearance. Every Calhoun super Structure is galvanized according to long-established, well accepted and approved standards of ASTM, the Canadian Standards Association (CSA), and the American Standards of State Highway and Transportation Officials (AASHTO). These standards cover everything from minimum required coating thickness for various categories of galvanized items to the composition of the zinc metal used in the process.