TELEDYNE OPTECH

Industrial Lasers

Advanced laser-based range finding instruments

Laser based Level and Process measurement has become indispensable to industry by allowing continuous measurements in hazardous locations and environments that often impede the performance of more conventional non-contact technologies. The compact units can be easily mounted where needed, will automatically detect levels and regularly transmit with a user adjustable update rate of up to 5 per second. Optech systems in particular are designed for the harshest environments, are explosion proof, and have been rated for operation in hazardous locations.

The ultimate solution for industrial process challenges, Optech’s laser rangefinders exploit the unique properties of light to produce precise, reliable, and fast measurements. High update rates provide accurate measurements even when objects move or change appearance quickly, or when material levels change rapidly. “Last-pulse logic” and internal windowing software filter out false returns from temporary obstacles passing between the rangefinder and the object or material.

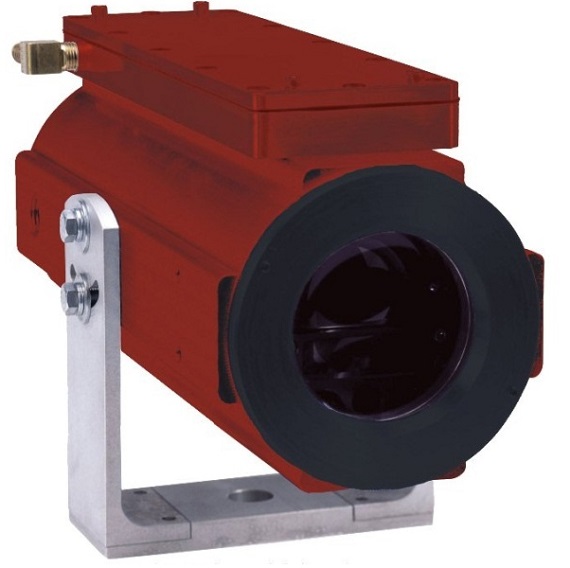

Sentry Level Monitor

Optech is the market leader in advanced laser-based range finding instruments, with clients world-wide. Originally considered an outsider, Laser Process Measurement has taken its rightful place in industry by allowing measurements in hazardous locations and environments that often impede the performance of more conventional non-contact technologies. The ultimate solution for industrial process challenges, Optech’s laser rangefinders exploit the unique properties of light to produce precise, reliable, and fast measurements. High update rates provide accurate measurements even when objects move or change appearance quickly, or when material levels change rapidly. “Last-pulse logic” and internal windowing software filter out false returns from temporary obstacles passing between the rangefinder and the object or material.

Optech Time-of-Flight (TOF) Lidar Technology:

Rapid measurements: Up to 5 Hz

Accurate: Absolute (“out-of-box”) accuracies of 2-4 cm (repeatability of 2 mm once adjusted against known references)

Non-contact, non-intrusive measurements

Narrow beam divergence permits flexibility in mounting locations and allows measurements through structural obstacles and measurement-interfering equipment such as agitators

Laser measurements unaffected by moderate amounts of dust, mounting angle or orientation, low/high/varying temperature of material or vessel interior, material angle of repose, background noise, vehicle or equipment vibration, vapor pressure, o¬ff-gas layers or steam, vacuum barriers, or low dielectric constant of material

• Applications

• Level Monitoring (Solid)

Made to Measure!

• Factory-calibrated, ready to measure

• Quick to set up, easy to service – no plant down-time

• Low maintenance, no moving parts

• Completely eye-safe

• RS-232C and isolated analog outputs

• Rugged, industrial-rated, explosion-proof enclosure

• CSA, CE, FM approved

• Applications

○ Level Monitoring (Liquid)

○ Liquid asphalt

○ Polymerization reactor vessels (under high pressure)

○ Reactor vessels (under vacuum)

○ Molten glass

○ Gels and high-fouling compounds

○ Ferrous and non-ferrous metals and alloys

• Level Monitoring (Solid)

○ Polystyrene, nylon and PRVC pellets

○ Talc and lime powders

○ Aggregates and granules

○ Ore and muck in ore passes

○ Wet or dry wood chips

○ Coal stacking

○ Coal bunker level

• Positioning Applications

• Positioning Applications

○ Waste water treatment digester roof height

○ Storage tank floating roof height

○ Asphalt paper tension monitoring (“looper” control in shingle manufacturing)

○ OSB manufacturing (horizontally-discharging chip bin)