Beka-Lube Products Inc

Industrial Lubrication Systems

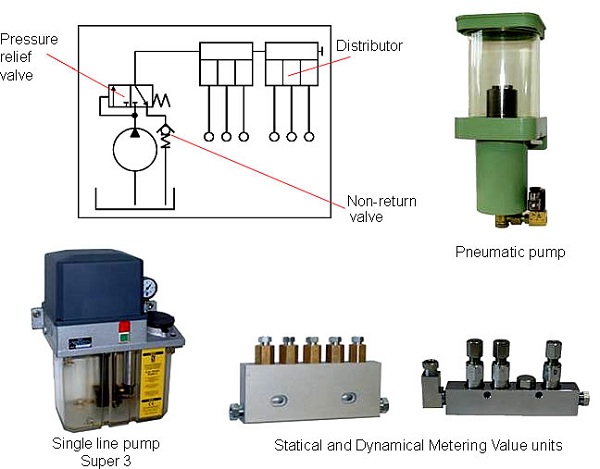

Single Line Systems

Single line central lubrication systems supply lubricant to bearings on a cyclical pressure basis. Applications demand a wide range of pumps and system components.

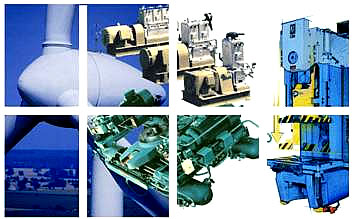

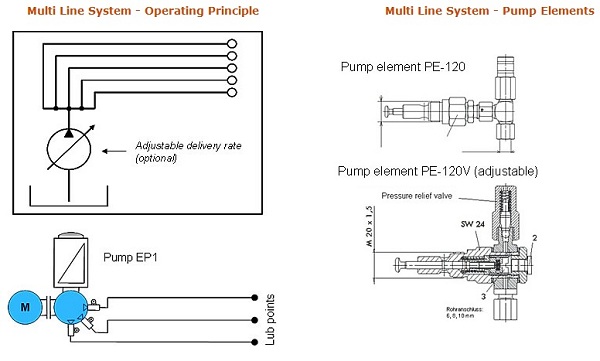

Multi Line Systems

Since 1927, BEKA has designed and built this traditional range of oil and grease lubrication pumps. The current range of multi line centralized lubrication offers solutions for all line classes and drive types.

Progressive and Dual Line Systems

The dual line system represents the classic solution for lubricating large plants. Progressive distributors are indispensable within modern central lubrication systems as they can cover several lubrication sites with only one supply.

Oil Recirculation Systems and Gear Pumps

BEKA designs and supplies oil circulating systems from the pump station and the oil distribution up to the complete piping layout.

Single line central lubrication systems supply lubricant to bearings on a cyclical pressure basis. Applications demand a wide range of pumps and system components.

Single line central lubrication systems supply lubricant to bearings on a cyclical pressure basis. Applications demand a wide range of pumps and system components.

The BEKA range includes hydraulic, pneumatic, manual and motorized units to match the specific application.

Lubricant: Oil and vicious oil NLGI 000-00

Application

To supply the lubrication requirements of small and medium sized machines, machinery groups and plants, such as machine tools, machining centres, weaving machines, textile machinery

Since 1927, BEKA has designed and built this traditional range of oil and grease lubrication pumps. The current range of multi line centralized lubrication offers solutions for all line classes and drive types.

Since 1927, BEKA has designed and built this traditional range of oil and grease lubrication pumps. The current range of multi line centralized lubrication offers solutions for all line classes and drive types.

Lubricant: Oil, vicious oil NLGI 000,00 and grease up to NLGI 3

Application

For small machines and groups of machinery with a low number of lubrication points, such as compressors, vacuum pumps, bakery machines, chain lubrication, presses, punches, timber yards

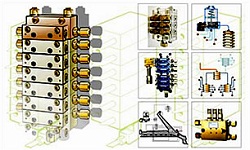

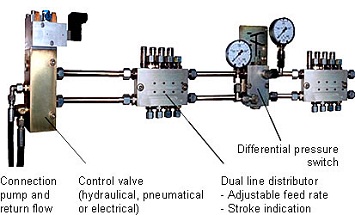

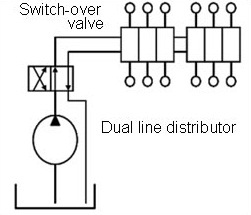

The dual line system represents the classic solution for lubricating large plants. Progressive distributors are indispensable within modern central lubrication systems as they can cover several lubrication sites with only one supply. Push-pull dosing pistons allow an effective monitoring of the distribution.

The dual line system represents the classic solution for lubricating large plants. Progressive distributors are indispensable within modern central lubrication systems as they can cover several lubrication sites with only one supply. Push-pull dosing pistons allow an effective monitoring of the distribution.

BEKA supplies progressive distributors for all areas of application.

Lubricant: Oil and vicious oil up to NLGI 3

Application

Progressive system:

Progressive system:

For machines, machine groups and plants where the lub points can be collected in groups, such as presses, punches, cranes.

Dual line system:

For machines and plants where the groups of lub points are widely separated, such as steel industry, paper machines, coal mining, timber yards

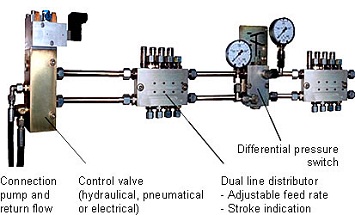

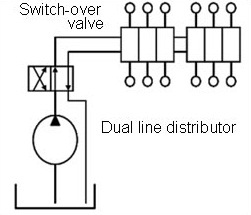

Progressive and Dual Line System - Operating Principle

Beka Industrial Progressive and Dual Line System The dual line system delivers the lubricant over a switch-over valve and two main lines to the dual line distributors.

Progressive and Dual Line System - Example of Application

Opencast mining excavator

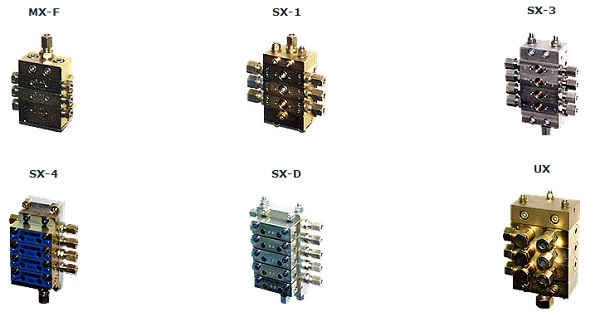

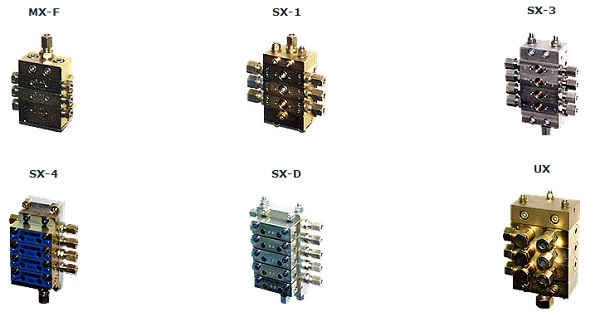

Progressive System - Distributor Types

Progressive and Dual Line System - Example of Application

Opencast mining excavator

Progressive System - Distributor Types

BEKA designs and supplies oil circulating systems from the pump station and the oil distribution up to the complete piping layout.

BEKA designs and supplies oil circulating systems from the pump station and the oil distribution up to the complete piping layout.

Gear pumps from our own production can be adapted in construction and form to the requirements of the customer.

Lubricant: Oil

Application

For all machinery and plants requiring an oil circulation lubrication with or without cooling effect, such as rolling mills, calenders, gear boxes, printing presses, presses, paper machines

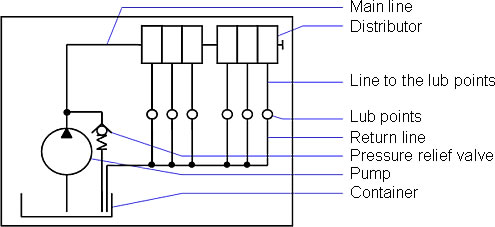

Oil Circulating System - Operating Principle

Customized design

• Container up to 12.000 liters and more

• With heating for separate thermo oil

• Oil cooler

• With electronic control